Are you curious about what sets gummy bears apart from energy chews in their manufacturing process?

Gummy bears and energy chews differ significantly in their production processes due to their unique ingredients and intended uses. While gummy bears primarily use gelatin, sugar, and corn syrup, energy chews incorporate active ingredients like caffeine or vitamins. This distinction leads to different cooking temperatures, molding techniques, and texture outcomes.

Quick Comparison of Manufacturing Processes for Gummy Bears and Energy Chews?

This comparison highlights the distinct ingredients and orocessing techniques required for each product type.

| Aspect | Gummy Bears | Energy Chews |

|---|---|---|

| Primary Ingredients | Gelatin, sugar, corn syrup | Sweeteners, binders, active ingredients |

| Cooking Temperature | High (240°F / 115°C) | Low (preserves heat-sensitive actives) |

| Shaping Method | Deposited into molds | Pressed or extruded into shape |

| Cooling Process | Long cooling (overnight) | Minimal cooling |

| Texture | Chewy with gel-like consistency | Soft and pliable |

| Coating | Glossy finishes with oil or sugar | Powder or minimal coating |

Understanding these differences can be crucial for manufacturers and businesses looking to optimize production or diversify product offerings. Dive deeper into the world of confectionery manufacturing as we unpack the intricate steps and techniques behind these beloved snacks.

Gummy bears use gelatin as a primary ingredient.True

Gummy bears are made with gelatin, sugar, and corn syrup.

Energy chews and gummy bears have identical cooking temperatures.False

Energy chews require different temperatures due to active ingredients.

What Ingredients Are Used in Gummy Bears vs. Energy Chews?

Gummy bears and energy chews are both popular snacks, but their ingredient lists differ significantly. While gummy bears focus on sweetness and texture, energy chews are designed to fuel activity. Let's explore these differences.

Gummy bears primarily contain gelatin, sugar, corn syrup, and water, focusing on taste and texture. In contrast, energy chews include active ingredients like caffeine or vitamins to enhance performance, often excluding gelatin for a softer texture.

Ingredients in Gummy Bears

Gummy bears are cherished for their chewy texture and vibrant flavors. The primary ingredients include:

- Gelatin: A protein derived from animal collagen, giving gummies their signature chewiness.

- Sugar and Corn Syrup: These sweeteners create the delightful taste that many enjoy.

- Water: Essential for mixing ingredients and achieving the right consistency.

- Flavorings and Colorings: Added after cooking to enhance taste and visual appeal.

The manufacturing involves heating the mixture to dissolve the gelatin and form a thick slurry, followed by flavoring, molding, and cooling. This creates the perfect gummy consistency that people love.

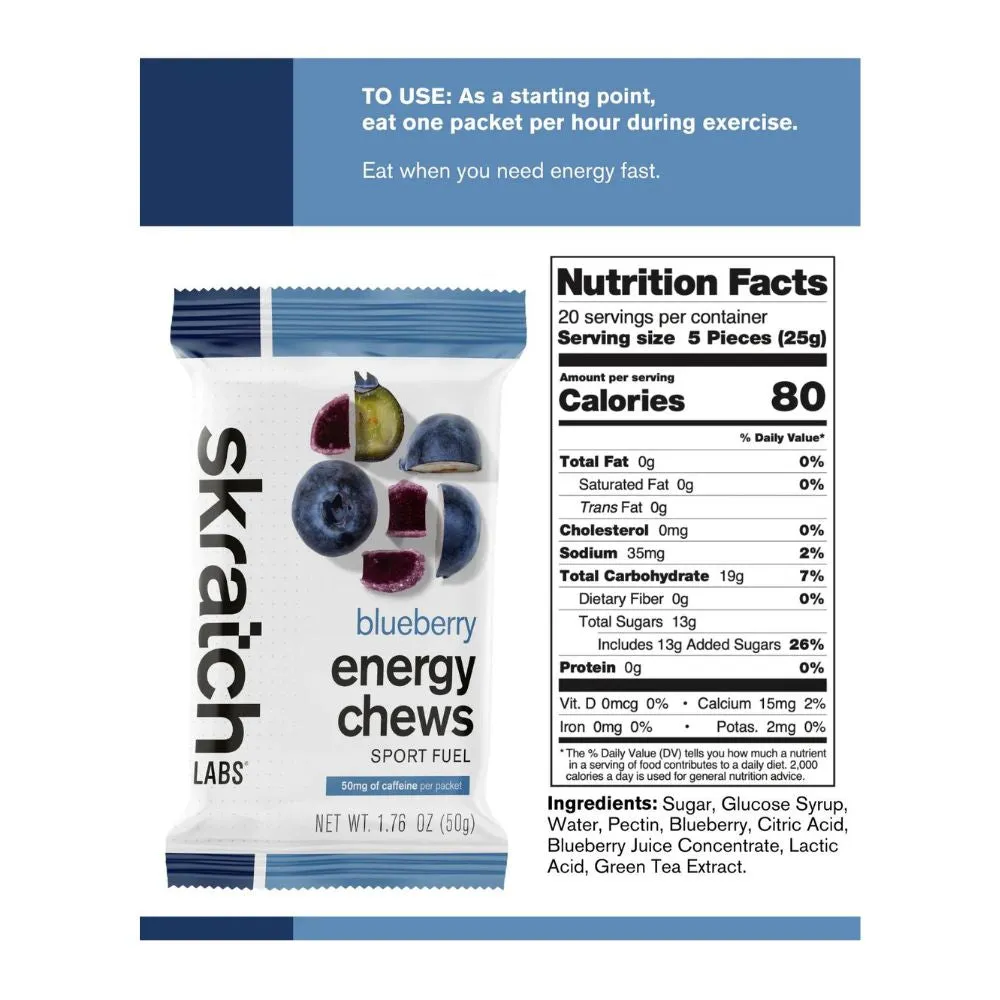

Ingredients in Energy Chews

Energy chews aim to provide a quick energy boost, hence their ingredients differ:

- Active Ingredients: These may include caffeine, electrolytes, or B vitamins to enhance endurance and alertness.

- Sweeteners and Binders: Used to create a palatable flavor while holding the chew together without gelatin.

Unlike gummies, energy chews use low-temperature processing to preserve heat-sensitive ingredients. They are often pressed into shape rather than molded, making them efficient for high-volume production.

For athletes or those seeking a performance edge, understanding these ingredients helps in selecting the right product. To explore more about nutritional benefits of energy chews1, check relevant resources for insights.

Additionally, energy chews are designed to maintain a softer texture while retaining moisture. Some varieties may include a coating to prevent sticking during packaging.

For further insights on how gelatin affects gummy bear texture2, delve into detailed studies that explore its unique properties.

Gummy bears contain caffeine for energy.False

Gummy bears focus on taste and texture, not energy-boosting ingredients.

Energy chews often exclude gelatin.True

Energy chews use binders instead of gelatin to retain a soft texture.

How Does the Cooking Process Affect Texture and Consistency?

Cooking transforms ingredients, affecting their texture and consistency. From chewy gummy bears to tender meats, understanding these changes can improve your culinary results. Let's explore how cooking alters these key attributes.

The cooking process affects texture and consistency by altering the physical and chemical properties of ingredients. Heat can break down proteins, starches, and fibers, leading to changes in firmness, moisture content, and overall mouthfeel.

Understanding the Science Behind Cooking

Cooking involves applying heat to food, which triggers a series of chemical reactions3 that fundamentally change the ingredients. For instance, proteins denature and coagulate when exposed to heat. This process tightens and firms up foods like meat and eggs.

Starch is another component that changes dramatically during cooking. Heat causes starch granules to absorb water, swell, and eventually gelatinize, which thickens sauces or gives pasta its desired texture.

The Role of Moisture

Moisture content is crucial for texture and consistency. During cooking, water can evaporate, leading to drier textures or concentrate flavors. Conversely, adding moisture through techniques like steaming or braising keeps foods tender.

For example, gummy bears4 rely on a precise balance of water and gelatin to achieve their chewy texture. Overcooking them can result in a hard, brittle product.

Cooking Techniques and Their Impact

Different cooking methods affect texture in unique ways. Grilling or frying introduces a crispy exterior through the Maillard reaction, while boiling softens food by breaking down its cellular structure.

Slow-cooking methods like braising allow connective tissues in meats to break down, resulting in a tender, melt-in-your-mouth experience. In contrast, high-heat5 methods like searing lock in juices but require precise timing to avoid toughness.

Considerations for Consistency

Consistency refers to the uniformity of a dish's texture throughout. This can be influenced by ingredient ratios, cooking time, and temperature control. Achieving the perfect sauce consistency often requires understanding how thickeners like cornstarch or roux interact with heat and liquid.

In summary, mastering the cooking process is key to controlling texture and consistency. By adjusting heat levels and cooking times, chefs can manipulate food properties to create the desired end result.

Heat causes proteins to coagulate and firm up.True

Heating denatures proteins, causing them to unfold and form a firm structure.

Boiling makes food crispy through the Maillard reaction.False

Boiling softens food; the Maillard reaction requires dry heat for crispiness.

Why Is Molding Different for Gummy Bears and Energy Chews?

Ever wondered why your favorite gummy bears have that perfect shape while energy chews seem less uniform? The secret lies in their distinct molding processes.

Gummy bears and energy chews are shaped using distinct methods to achieve their unique textures and meet composition requirements. Gummy bears are typically formed using cornstarch, metal, or silicone molds, giving them their signature chewy texture. In contrast, energy chews are pressed into shape, resulting in a softer consistency.

Ingredient Composition and Its Impact on Molding

The fundamental difference between gummy bears and energy chews starts with their ingredients. Gummy bears rely heavily on gelatin, which requires high-temperature cooking to dissolve and integrate with sugars. This creates a thick slurry that's perfect for cornstarch molding6. Cornstarch absorbs excess moisture, allowing the gummy mixture to set into the desired shape while ensuring a chewy consistency.

Starchless depositing uses silicone or metal molds, which eliminate the need for cornstarch molds and streamline the gummy-making process. This method is cleaner, faster, and suitable for high-precision production, making it ideal for pharmaceutical or nutraceutical gummies. It accommodates complex designs, such as multi-color or center-filled gummies, with greater consistency. Additionally, starchless depositing reduces waste and simplifies cleaning, enhancing operational efficiency.

Energy chews, on the other hand, often incorporate various active ingredients like caffeine or vitamins, mixed with sweeteners and binders. These components are sensitive to heat, necessitating low-temperature processing. Instead of molding, energy chews are typically shaped by compressing the mixture using specialized machinery. This method is not only efficient but also preserves the active ingredients' efficacy.

Cooling and Setting Processes

The cooling phase also highlights differences in the two confectioneries. Gummy bears are left to cool overnight within their molds to ensure they achieve the correct firmness. This lengthy setting time is essential for maintaining their gel-like texture. On the flip side, energy chews undergo minimal cooling, retaining moisture for a soft and pliable texture. This difference in cooling is crucial for businesses aiming to produce large quantities efficiently without compromising quality.

The Role of Coatings

Post-molding, gummy bears and energy chews may receive additional coatings. Gummy bears often get a mineral oil or sugar coating to enhance their appearance and prevent sticking. Conversely, energy chews might focus on maintaining a softer texture rather than achieving a glossy finish. Gummy production equipment7 can offer specialized solutions for these processes, ensuring each product's unique characteristics are preserved.

Understanding these distinct molding techniques allows manufacturers to tailor their processes, optimizing production efficiency while meeting consumer expectations for texture and flavor.

Gummy bears use gelatin for molding.True

Gummy bears rely on gelatin, which sets into a chewy texture when molded.

Energy chews are molded using cornstarch.False

Energy chews are pressed, not molded with cornstarch, to preserve ingredients.

What Are the Packaging Considerations for Gummies and Enery Chews?

Packaging can make or break a product's success. From maintaining freshness to standing out on shelves, each product requires unique packaging considerations.

Packaging considerations vary by product and involve factors like material choice, size, sustainability, and branding. Each aspect influences cost, market appeal, and functionality, requiring careful evaluation to ensure product success.

Material Selection

Choosing the right material is crucial for both protecting the product and appealing to consumers. For example, gummy bears8 require airtight packaging to maintain freshness and prevent moisture exposure. In contrast, energy chews may need packaging that emphasizes durability and ease of access.

Size and Shape

The size and shape of packaging must align with distribution needs and consumer convenience. Smaller items like individual energy chews might benefit from single-serve packages, whereas bulk packages could be more suitable for retail environments.

Sustainability

Eco-friendly packaging is becoming increasingly important as consumers demand sustainable options. Opting for biodegradable or recyclable materials can enhance brand image and meet regulatory requirements. For instance, using recycled plastics9 can reduce environmental impact while still providing necessary protection.

Branding and Design

Packaging is a critical element of branding. It must convey the product's identity and attract customers visually. Consider how colors, logos, and text can communicate quality and stand out on shelves. Creative designs often lead to improved brand recognition and customer retention.

Cost Implications

Every packaging decision has financial implications. Balancing cost with quality is key to maintaining profitability. Assessing the cost-effectiveness of materials without compromising on quality or appearance is crucial for business success.

Regulatory Compliance

Different products have specific regulatory requirements concerning packaging. Ensure all labels provide necessary information such as ingredients, nutritional content, or safety warnings to comply with local regulations.

Exploring these factors helps businesses create packaging solutions that not only protect their products but also enhance their market appeal and sustainability goals. For a deeper understanding, consider looking into packaging trends10 within your industry to stay competitive.

Gummy bears require airtight packaging for freshness.True

Airtight packaging prevents moisture exposure, preserving gummy bears' quality.

Eco-friendly packaging is irrelevant to modern consumers.False

Consumers increasingly demand sustainable options, enhancing brand image.

Conclusion

Manufacturing gummy bears and energy chews involves distinct processes that reflect their unique formulations, textures, and intended uses. Gummy bears rely on gelatin, precise heating, and advanced depositing techniques to achieve their signature chewy texture, while energy chews use low-temperature processing, binders, and compression or extrusion methods to create a softer, pliable product. These differences not only impact production techniques but also determine the required machinery and manufacturing workflows.

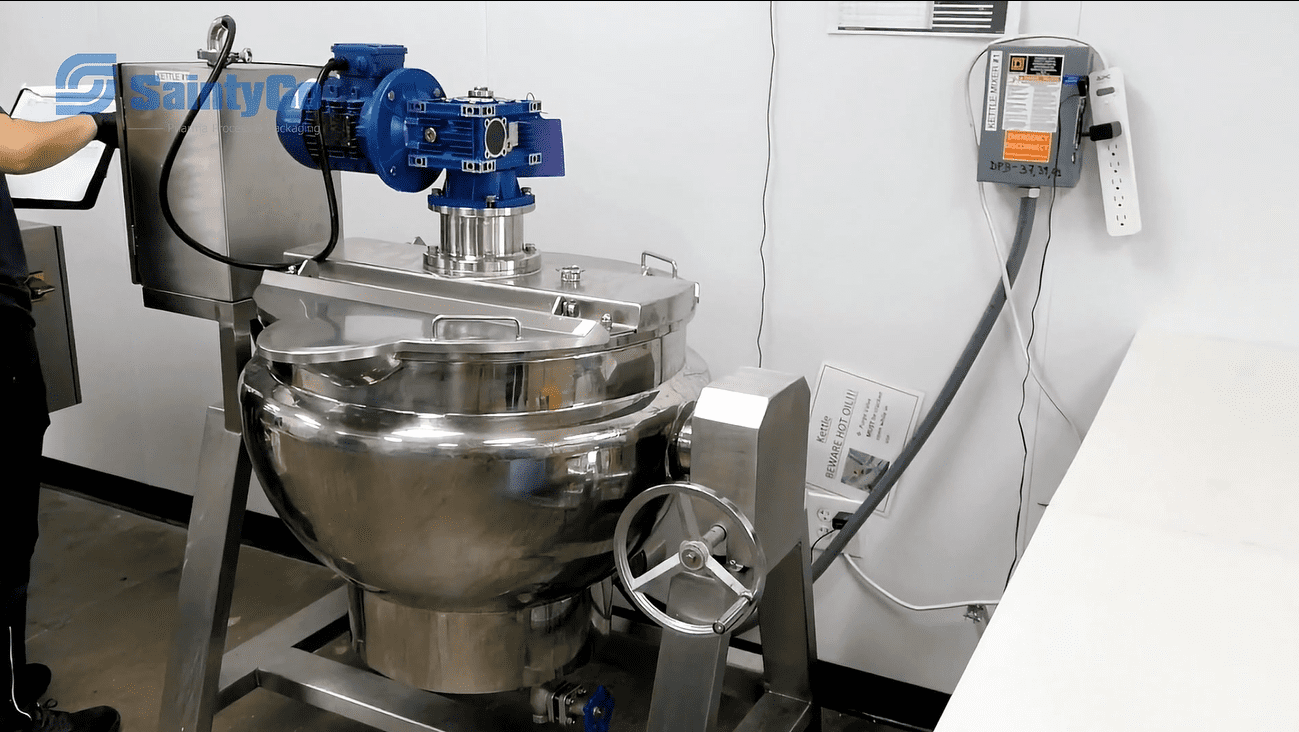

Work with GummyGenix by SaintyCo

At GummyGenix by SaintyCo, we offer advanced equipment and tailored solutions for gummy bear production and energy chew manufacturing.

Whether you’re looking to upscale your gummy bear manufacturing with starchless depositing systems or exploring equipment solutions for high-viscosity energy chew production, our team is ready to support you at every step. Our customizable machinery and process optimization services ensure that your products stand out in the competitive market.

Contact us today to explore innovative solutions and grow your manufacturing capabilities.

-

Learn how energy chews aid athletic performance with essential nutrients and boost energy levels. ↩

-

Discover how gelatin contributes to the chewy texture of gummy bears and its role in production. ↩

-

This link provides insights into the chemical changes that occur when cooking, essential for understanding food texture. ↩

-

Explore how specific ingredients contribute to the chewy texture of gummy bears. ↩

-

Learn about the Maillard reaction's role in creating crispy textures during cooking. ↩

-

Explore how cornstarch molds contribute to the unique texture of gummy bears, offering insights into this crucial manufacturing step. ↩

-

Discover advanced equipment options that streamline gummy production, enhancing quality and efficiency in manufacturing. ↩

-

Discover specific packaging needs for gummy bears to ensure freshness and appeal. ↩

-

Learn how recycled plastics can improve sustainability without compromising quality. ↩

-

Stay updated on innovative design trends to enhance your product's market presence. ↩