For gummy manufacturers, maintaining consistent quality and texture in production is essential to meet regulatory standards1 and satisfy customer expectations. However, numerous factors—ranging from precise ingredient ratios to stringent humidity and temperature control—affect gummy production quality and consistency. By understanding these variables, manufacturers can optimize their processes, producing gummies that not only look and taste great but also maintain structural integrity over time.

Maintaining gummy production quality and consistency hinges on key factors such as humidity control, exact ingredient ratios, and specialized equipment calibration. Optimal gummy manufacturing also relies on selecting the right binding agents, like gelatin or pectin, and managing processing parameters to ensure that each gummy meets the desired standards in flavor, texture, and shelf life.

Let us explore the primary factors affecting gummy production quality and consistency, examining each process and technique used to control these elements for optimal results.

Precise ingredient ratios and environmental control are essential for consistent gummy production quality.True

Maintaining consistent ingredient ratios and humidity helps ensure uniform texture and flavor in each gummy batch.

What Factors Influence Gummy Consistency?

In gummy production, texture and consistency are greatly affected by ingredient choices, especially the types of binding agents like gelatin and pectin2 as well as by environmental conditions.

The choice of binding agents like gelatin and pectin is central to gummy consistency. Gelatin provides a chewy, elastic texture, while pectin offers a firmer bite. Adjusting these ingredients lets manufacturers fine-tune texture for various consumer preferences.

1. The Science of Gelatin and Pectin in Gummy Consistency

- How Gelatin Creates Chewiness in Gummies: Gelatin is the primary binding agent in gummy production, responsible for the elastic, chewy texture that customers expect. When gelatin is combined with water and heated, it forms a flexible network that gives gummies their structure. Adjusting gelatin levels allows manufacturers to control the exact elasticity and mouthfeel.

- Pectin for Firm, Vegan-Friendly Gummies: Pectin, derived from fruits, provides an alternative to gelatin. Its short, firm bite makes it ideal for vegan or health-conscious markets. Pectin requires precise pH levels and temperature control to achieve consistent texture.

- Modifying Gummy Texture with Ingredient Ratios: Balancing gelatin and pectin allows manufacturers to customize the texture. Increasing pectin levels yields a firmer product, while increasing gelatin creates a stretchier bite, catering to varied consumer preferences.

Gelatin is the primary binding agent for chewy gummies.True

Gelatin creates an elastic, chewy texture when heated and combined with water, forming a flexible network essential for traditional gummies.

Adjusting gelatin levels does not significantly change gummy texture.False

Increasing gelatin concentration directly affects chewiness and mouthfeel, enabling manufacturers to modify the gummy texture according to consumer preference.

2. Impact of Ingredient Ratios in Gummy Production Quality

- Gelatin Concentration for Precise Texture Control: Higher gelatin levels increase chewiness, a factor valued in adult gummies or nutraceuticals, as these products often have unique textural needs.

- Incorporating Texture-Stabilizing Additives: Corn syrup3 and other stabilizers maintain softness and prevent crystallization, enhancing mouthfeel and extending shelf life. These additives are essential for achieving reliable texture across large batches.

- Flavor-Taste Synergy for Consumer Appeal: Certain flavors pair better with specific textures, creating a seamless sensory experience. For example, fruit-flavored gummies often work best with a softer, pectin-based texture.

Higher gelatin levels increase gummy firmness.True

Increasing gelatin concentration in the mixture yields a firmer, more resilient gummy texture.

Flavor selection does not impact gummy texture.False

Certain flavors pair better with specific textures, impacting the overall sensory experience of the gummy.

3. Humidity and Environmental Control in Gummy Manufacturing for Consistent Texture

-

Controlling Temperature Sensitivity of Gelatin and Pectin: Both ingredients require precise temperature control during cooking and cooling, as variations can lead to texture issues. For example, overheating gelatin can break down its structure, resulting in a less elastic gummy.

-

Humidity’s Role in Production and Storage: Humidity control4 during production and storage is essential for preventing gummy stickiness or moisture imbalances, which impact texture and quality. Production rooms must have regulated humidity to keep gummies at their optimal consistency.

-

Maintaining a Stable Environment for Quality Assurance: Gummy consistency can vary with fluctuations in environmental factors, underscoring the need for stable, controlled manufacturing environments.

Maintaining strict control over temperature and humidity is essential for achieving consistent gummy quality. Variations in these conditions can lead to texture inconsistencies, stickiness, or hardness in gummies. GummyGenix by SaintyCo's gummy manufacturing equipment, such as the fully automated G80 and G300 production lines, features advanced cooling systems equipped with chilling fans and dehumidification technology, maintaining a stable 0-20℃ environment. This setup is designed to ensure each gummy is produced with a uniform texture, meeting high standards of quality and shelf life.

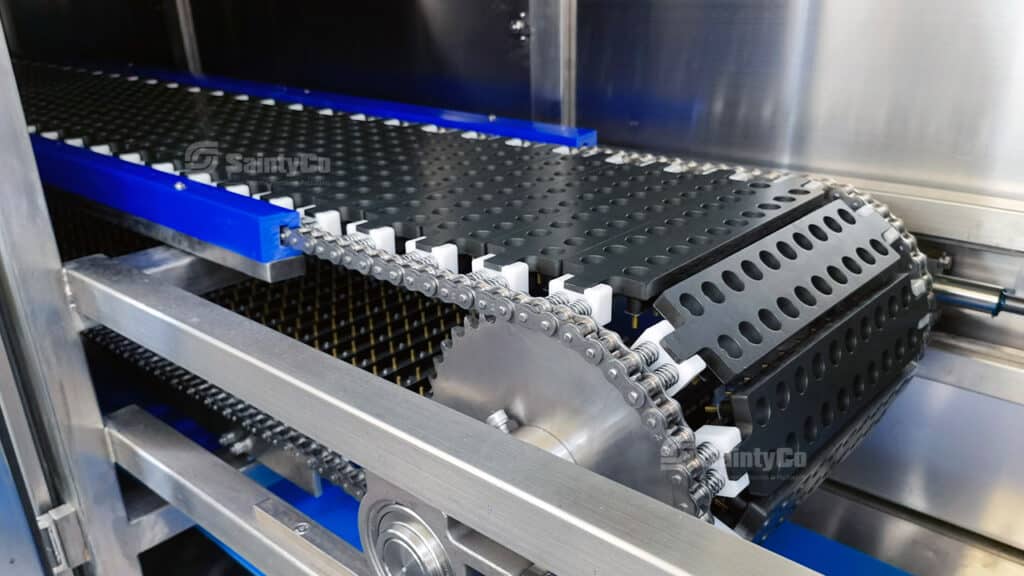

4. Importance of Equipment Calibration and Automation

Accurate equipment calibration and automation are vital for achieving uniform gummy size, shape, and weight. GummyGenix by SaintyCo’s gummy machines are all equipped with servo-driven depositors and intuitive PLC touch screens, enabling operators to adjust depositing parameters with ease. This precision ensures consistent quality across each production run, reducing manual intervention and error. These advanced features streamline production, enhance efficiency, and provide the consistency needed to meet high standards in gummy manufacturing.

How Does Gelatin Affect Gummy Firmness?

Firmness in gummy production is achieved by manipulating gelatin levels and controlling the cooling process. These factors allow manufacturers to create gummies with specific textural qualities.

In gummy production, higher gelatin concentrations lead to firmer, chewier gummies, while cooling techniques influence the final texture and firmness. This allows manufacturers to create varied products suited to market needs.

1. Gelatin Levels: Fine-Tuning Firmness in Gummy Production

- Increasing Gelatin for Greater Firmness: Adding more gelatin to the gummy base directly increases firmness, creating a denser, longer-lasting chew. This is especially popular in gummies geared toward adult or medicinal use, where a firmer bite may be preferred.

- Vegan Alternatives for Firmness: Agar-agar and pectin serve as popular alternatives for vegan gummies. Though pectin gummies are naturally firmer, achieving consistent firmness with agar requires strict control of pH levels and temperatures.

- Ensuring Consistent Firmness Across Production: To achieve uniformity, manufacturers often pre-mix gelatin with other ingredients to avoid clumping and achieve even distribution, ensuring firmness remains consistent in every batch.

Higher gelatin concentration leads to firmer gummies.True

Increasing gelatin levels results in a firmer gummy, providing a chewier experience for certain markets.

Agar and pectin cannot replicate the firmness of gelatin.False

With precise control over pH and temperatures, agar and pectin can achieve comparable firmness, though they offer different texture profiles.

2. Cooling Techniques for Enhanced Gummy Firmness

- Rapid Cooling vs. Gradual Cooling: Rapid cooling produces firmer gummies, which helps maintain shape and reduces the risk of texture degradation. Gradual cooling, on the other hand, allows for a softer texture, which is ideal for children’s gummies or less robust formulas.

- Impact of Advanced Cooling Equipment: State-of-the-art cooling systems with precision temperature controls allow manufacturers to fine-tune gummy firmness, giving greater flexibility for diverse market demands.

- Standardizing Cooling Times for Texture Control: For uniform gummy firmness, precise cooling times are essential. Deviations in cooling can create textural inconsistencies, particularly in larger production runs.

3. Environmental Factors and Post-Production Firmness

- Temperature Stability During Storage: Ambient temperatures affect post-production firmness, especially if products are exposed to fluctuating temperatures during shipping or storage.

- Humidity’s Influence on Firmness Retention: Low-humidity packaging helps preserve gummy firmness, while excess moisture can soften gummies, leading to inconsistency.

- Protective Packaging for Firmness Maintenance: Packaging designed for moisture resistance is crucial for preserving gummy texture, especially in markets where shelf life and stability are essential.

How Do Ingredients Impact Gummy Texture?

Gummy texture is the product of carefully selected ingredients. Each component, from glucose syrup to citric acid, contributes distinct qualities to the final product’s texture.

In gummy manufacturing, core ingredients like gelatin, glucose syrup, and citric acid create the desired chewy texture and smooth mouthfeel. Adjusting these components lets manufacturers tailor texture profiles for specific markets.

1. Key Ingredients Shaping Gummy Texture

- Gelatin and Pectin’s Textural Roles: Gelatin provides elasticity, creating a soft, chewy texture ideal for traditional gummies. Pectin’s firmer texture is popular for health-conscious markets and provides a shorter bite.

- Glucose Syrup for Smooth, Non-Crystalline Texture: Glucose syrup prevents crystallization, which is essential for maintaining a smooth gummy mouthfeel. It also helps balance sweetness, ensuring a palatable taste.

- Citric Acid for Tang and Stability: Citric acid not only adds a tangy flavor but also stabilizes the gummy mixture, preventing spoilage and enhancing shelf life.

2. Moisture Management and Texture Control in Gummy Production

- Mixing for Moisture Consistency: Precise moisture levels during mixing allow for uniform texture across the batch, avoiding issues like dryness or stickiness.

- Preventing Stickiness in Packaging: Too much moisture can lead to sticky gummies, which impacts packaging and can lower customer satisfaction.

- Optimal Moisture Levels for Longevity: Consistent moisture control is crucial to prevent texture degradation and maintain quality through the gummy’s shelf life.

3. Color and Flavor Additives’ Influence on Texture

- Compatibility of Additives with Core Ingredients: Certain colors or flavors can alter gummy texture, so it’s important to select additives that integrate well with the formula.

- Flavor Distribution Consistency: Evenly dispersing flavors in the batch maintains batch quality and ensures a uniform taste experience.

- Natural vs. Synthetic Additives and Their Textural Impact: While natural additives appeal to health-conscious consumers, synthetic options often deliver more consistent textures and extended shelf life, which can be critical for specific markets.

Additives do not alter gummy texture.False

Certain colors and flavors can affect gummy texture, making it essential to choose compatible additives.

Synthetic additives offer more consistent textures than natural ones.True

Synthetic options often provide uniform texture and longer shelf life, while natural additives may vary in effect.

What is the Gummy Manufacturing Process?

The gummy manufacturing process, from ingredient mixing to packaging, is meticulously structured to ensure consistent quality and texture across batches.

Gummy manufacturing involves precise mixing, cooking, depositing, and cooling techniques, each stage contributing to the final product's quality and consistency.

1. Mixing and Cooking: Foundations of Gummy Quality Control

- Ingredient Consistency and Pre-Mixing: Ensuring ingredients are evenly pre-mixed avoids inconsistencies in texture or flavor across the batch, laying the groundwork for uniform gummies.

- Precision in Cooking Temperature for Texture Quality: Maintaining the correct temperature is critical, as fluctuations can impact both texture and flavor, leading to batch inconsistency.

- Timing and Texture in Cooking: Cooking time impacts the gummy’s final texture—longer cooking yields denser gummies, while shorter times yield softer, lighter products.

Uniform ingredient mixing is essential for consistent gummy texture and flavor.True

Pre-mixing ingredients evenly ensures consistency in texture and flavor across batches, reducing variations that could impact quality.

Cooking temperatures do not affect gummy texture.False

Temperature precision during cooking is crucial; fluctuations can cause texture changes, impacting both softness and chewiness.

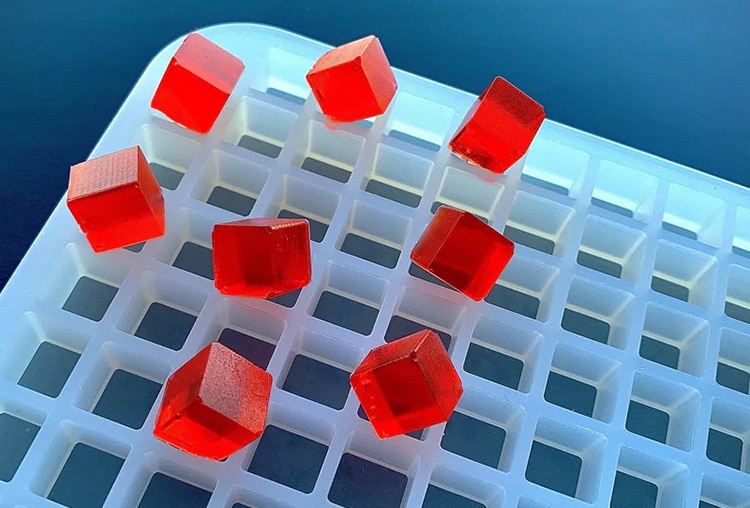

2. Depositing and Molding Techniques for Gummy Consistency

- Precision in Depositing Temperature: Controlling depositing temperature is key to preventing texture issues like air bubbles, which impact uniformity.

- Calibrating Pressure and Speed: Adjustments in pressure and speed help maintain consistent size and shape, ensuring each gummy meets brand standards.

- Impact of Mold Design on Perceived Texture: Custom molds offer a way to subtly influence texture perception, enhancing product appeal through visual and tactile experience.

3. Cooling and Packaging to Ensure Shelf Life

- Cooling for Consistency and Textural Stability: Proper cooling processes stabilize gummies, ensuring texture retention over time.

- Packaging for Quality Preservation: Packaging that resists moisture is essential for preserving texture, especially in regions with high humidity.

- Optimizing Storage and Shipping Conditions: Stable shipping environments protect against texture changes, preserving quality from production to consumer.

Conclusion: Mastering Quality and Consistency in Gummy Production

In the competitive world of gummy production, achieving consistent quality and texture is no small feat. Every stage of the manufacturing process—from choosing the right ingredients like gelatin and pectin to precisely controlling environmental factors—plays a pivotal role in shaping the final product. By carefully managing ingredient ratios, optimizing equipment settings, and maintaining strict control over temperature and humidity, gummy manufacturers can produce batches that meet both consumer expectations and regulatory standards.

Incorporating advanced techniques in cooling, packaging, and environmental management helps ensure that gummies retain their intended firmness, flavor, and texture over time, providing a product that consumers love and trust. With

-

Learn about the regulatory requirements for dietary supplements from the FDA: This guide helps gummy manufacturers ensure their products comply with U.S. standards to maintain consumer safety and quality. ↩

-

Compare gelatin and pectin as binding agents in gummies: Gelatin provides a chewy texture, while pectin offers a firmer bite, catering to different consumer preferences and dietary needs. ↩

-

Explore the role of corn syrup in gummy production: helps maintain gummy texture by preventing crystallization, ensuring a smooth and enjoyable mouthfeel. ↩

-

Discover best practices for managing humidity in gummy manufacturing: Proper humidity control is essential for preventing texture issues and maintaining consistent gummy quality. ↩