Gummy vitamins, one of the most popular forms of supplements today, offer a convenient and tasty alternative to traditional pills. However, like all supplements, gummy vitamins have a shelf life. So, do gummy vitamins expire? Here’s what you need to know about their longevity and the factors that impact their potency and effectiveness.

Gummy vitamins do expire, typically losing potency over time. However, learning how to increase the shelf life of gummy vitamins through proper storage—such as keeping them in cool, dry conditions—can ensure they remain effective for longer periods.

A Common Misconception About Gummy Products

There is a common misconception in both the pharmaceutical and confectionery industries that gummy vitamins, supplements, and candies do not expire. This misunderstanding leads to ineffective gummy vitamin spoilage prevention. While these products are shelf-stable, they are not immune to expiration.

Gummy products contain water, which affects their freshness and safety over time. Gummy vitamins may appear fine but could lose their potency as their active ingredients degrade. In some cases, microbial growth may occur, making them unsafe for consumption.

.

How Long Are Gummy Vitamins Good After Expiration?

Most gummy vitamins remain effective for up to two years if stored properly. After this, the active ingredients begin to degrade. While they may still be consumable for a short time, it’s important to inspect them for signs of spoilage such as mold, discoloration, or texture changes.

.

Is It Safe To Consume Expired Gummy Vitamins?

Expired gummy vitamins typically won’t spoil like food, but without proper gummy vitamin spoilage prevention, they can lose potency, effectiveness, and safety. It’s unlikely that expired gummies will make you sick, but you should check for mold, a foul odor, or discoloration. If any of these signs are present, discard them to avoid potential health risks.

Even if they appear safe, expired gummy vitamins may not provide the expected nutritional benefits due to ingredient degradation. This could result in nutrient deficiencies over time.

.

What Happens If you Take Expired Vitamins?

Taking expired vitamins, including gummies, won’t necessarily harm you, but their potency will be reduced. As vitamins lose effectiveness, they may not deliver the full health benefits you rely on. Over time, this could lead to nutrient deficiencies if you take them regularly.

.

.

How Do I Know If My Gummy Vitamins Are Bad?

Signs that your gummy vitamins have expired include:

- Texture changes: They may become hard, sticky, or too soft.

- Discoloration: Faded colors or mold spots indicate spoilage.

- Foul odor: A sour or off smell suggests the gummies are no longer safe.

- Loss of potency: If the benefits are less noticeable, the vitamins may have lost their effectiveness.

.

Do Gummy Vitamins Lose Potency?

Yes, gummy vitamins lose potency over time, especially if not stored correctly. Gummies are more sensitive to heat, light, and moisture than tablets, which accelerates their degradation. While they can last up to two years with proper storage, their potency diminishes gradually.

Factors affecting potency include:

- Water content: Gummies contain more water, which can lead to faster degradation.

- Storage conditions: Heat, moisture, or sunlight can further degrade the active ingredients.

.

How Can You Store Gummy Vitamins to Extend Their Shelf Life?

To extend the shelf life of gummy vitamins, store them in a cool, dry place, away from direct sunlight. Heat and moisture speed up the breakdown of active ingredients and promote mold growth. Use airtight containers or keep them in their original sealed packaging with desiccant inserts to maintain freshness.

.

How Important is Water Activity in Determining Gummy Vitamin Shelf Life?

Water activity (aW) is crucial for gummy vitamin spoilage prevention. It measures the amount of free water that can support microbial growth. Maintaining a water activity level between 0.35 and 0.45 helps ensure the product's longevity and stability.

.

Do Gummy Vitamins Have a Shorter Shelf Life Than Tablets?

Yes, gummy vitamins generally have a shorter shelf life compared to tablets due to their higher water content and sensitivity to heat, moisture, and light. Proper storage can help extend their shelf life up to two years, but tablets tend to last longer under similar conditions.

.

Best Practices for Gummy Vitamin Production to Extend Shelf Life

Implementing shelf life best practices for gummy vitamins is essential for product longevity. Several manufacturing processes can help extend the shelf life of gummy vitamins, including controlling water activity, using proper packaging, and conducting regular quality checks.

.

1. Improving Shelf Life with Proper Water Activity Control

Water activity (aW) is one of the most important factors in gummy vitamin spoilage prevention. Keeping the correct aW level ensures that gummies remain safe and effective. Too high, and they can develop mold; too low, and they become brittle and unstable.

Actionable Step: Use water activity meters to monitor aW during production. Maintaining a level between 0.35 and 0.45 inhibits microbial growth while ensuring the gummies remain chewy.

Example: Manufacturers can use automated monitoring systems to track aW levels in real time, adjusting moisture levels during cooking and cooling.

.

.

2. Use of Food-Grade Preservatives

Adding food-grade preservatives prevents microbial growth and extends the shelf life of gummy vitamins.

Actionable Step: Choose preservatives that comply with FDA standards and maintain the texture and taste of the gummies.

Example: Preservatives like sorbic acid or citric acid help keep gummies fresh without affecting their nutritional composition.

.

3. Moisture Control in Packaging

Proper packaging is one of the most important factors in gummy vitamin spoilage prevention. It is also a key component in following shelf life best practices for gummy vitamins, ensuring that they remain effective throughout their intended lifespan. Exposure to moisture during packaging can drastically reduce the shelf life of gummy vitamins. By incorporating desiccant inserts and ensuring airtight seals, manufacturers can prevent moisture buildup and spoilage. Manufacturers need to ensure that gummies are packaged in airtight, moisture-resistant containers. Incorporating desiccant inserts can also help absorb excess moisture and prevent spoilage.

Actionable Step: Employ packaging machines that create an airtight seal for each bottle or pouch and include moisture barriers in the packaging design. The use of nitrogen flushing during the packaging process can also help by removing excess oxygen and moisture from the container before sealing.

Example: Companies producing high-volume gummy vitamins can invest in automated packaging machines for gummies equipped with nitrogen-flushing technology to minimize moisture and oxygen, extending the shelf life of their products.

.

.

4. Regular Quality Control Checks Throughout the Manufacturing Process

Conduct regular quality control checks to ensure gummies meet safety standards. This includes checking texture, appearance, and water activity at various production stages.

Actionable Step: To implement the best practices for gummy vitamin production, establish a quality control checklist that includes routine testing for water activity, microbial contamination, and physical appearance. This ensures that products meet safety standards and have an extended shelf life. Utilize handheld water activity meters to measure moisture levels quickly, and test random batches for texture and taste to ensure no defects go unnoticed.

Example: A facility might implement a three-stage testing process where gummy vitamins are inspected for water activity during the cooling phase, before packaging, and as part of post-production testing to ensure they meet the shelf life standards.

.

.

Packaging and Storage for Extended Shelf Life

While the manufacturing process lays the foundation for how to increase the shelf life of gummy vitamins, proper packaging and storage are equally important. By using high-quality packaging materials and storing gummies in optimal conditions, manufacturers can significantly extend their shelf life.

.

5. High-Quality Packaging Materials

Using high-quality packaging materials is essential to maintaining the integrity of gummy vitamins. Packaging should be designed to block out UV light, moisture, and oxygen, all of which can degrade the active ingredients.

Actionable Step: Invest in multi-layered packaging that incorporates materials such as PET (Polyethylene Terephthalate) for light resistance and aluminum lining for moisture control. Additionally, consider re-sealable pouches that ensure the product remains fresh after opening.

Example: A manufacturer producing premium gummy vitamins may opt for UV-blocking bottles with desiccant inserts to ensure the product stays fresh, even after the consumer begins using it.

.

6. Cold Storage for Maximum Potency

Storing gummies in temperature-controlled environments can help preserve their potency.

Actionable Step: Designate a cold storage area with temperatures around 20°C (68°F) and humidity below 50% to maintain the quality of the vitamins.

Example: Large-scale production facilities can install climate-controlled storage rooms to retain potency.

.

Identifying and Resolving Quality Issues Before Distribution

Ensuring the quality of gummy vitamins before distribution is the final step in securing their shelf life. Identifying potential quality issues helps prevent spoilage before the products hit the shelves.

.

7. Conducting Sensory and Microbial Tests

Before distribution, conduct sensory tests (taste, smell, texture) and microbial tests to catch any quality issues.

Actionable Step: Regularly test random samples for texture, taste, and microbial activity.

Example: Automated testing can help monitor microbial contamination and ensure optimal water activity.

.

Ensuring Longevity with GummyGenix by SaintyCo’s Advanced Manufacturing Equipment

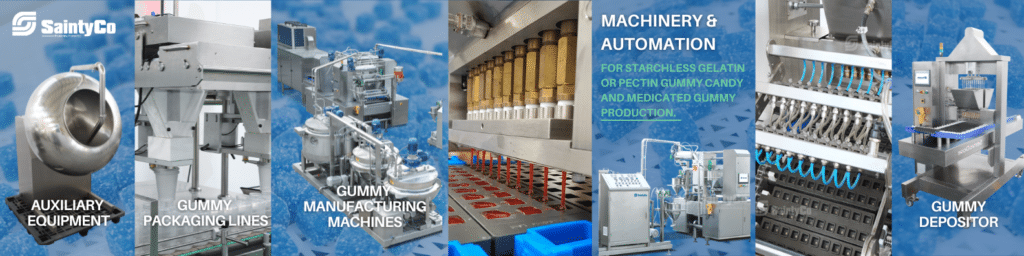

At GummyGenix by SaintyCo, we understand the importance of quality control and manufacturing precision for producing gummy vitamins with long shelf lives. Our advanced equipment helps businesses maintain optimal water activity levels, monitor for microbial growth, and meet rigorous safety and quality standards. Contact us today to learn how we can help your business produce high-quality gummy vitamins that remain safe and effective.

.

.

Summary

In conclusion, knowing how to extend the shelf life of gummy vitamins by following shelf life best practices for gummy vitamins is essential for maintaining potency and safety. Manufacturers can achieve gummy vitamin spoilage prevention by controlling water activity, using food-grade preservatives, and employing moisture-resistant packaging. With proper manufacturing and storage techniques, gummy vitamins can remain safe and effective for longer periods.

Interested in increasing the shelf life and safety of your gummy vitamins? Contact GummyGenix by SaintyCo for a consultation on our advanced gummy manufacturing equipment and automated packaging solutions for gummies.