The days of gummy bears being the only gummy candy on the block are long gone! Nowadays, gummies have exploded in popularity. Candy makers constantly push the boundaries to meet the growing demand for diverse and innovative options.

If you want to make different types of gummies and tap into your customers’ cravings and preferences, this is your inspiration. Read on to explore the various gummy types, trends, and possibilities that await you.

What Are Different Types of Gummy Candies?

The gummy market is booming! With more and more companies joining the scene, standing out from the competition is tougher than ever. To keep up, brands have poured time and resources into developing unique and enticing gummy creations. Here, we’ll explore popular gummy types according to different classifications:

1. Flavor-Based Gummies

Flavor-based gummies focus on the taste experience. They include classic fruit flavors and bold sour varieties that appeal to different demographics.

Key varieties include:

| Gummy Type | Description | Target Audience | Key Characteristics |

| Fruit-Flavored Gummies | Classic flavors like orange, strawberry, raspberry. | General consumers | Uses real fruit juice, appeals to health-conscious buyers, suitable for natural snack markets. |

| Sour Gummies | Bold, tangy flavors using citric acid or malic acid. | Gen Z, millennials | Popular for adventurous flavor seekers, influenced by social media trends like sour challenges. Seasonal/exotic flavors appeal to trend-driven consumers. |

.

2. Ingredient-Based Gummies

Ingredient-based gummies are categorized by the base ingredients used to create them, such as gelatin, pectin, or agar. These choices impact both the texture and target audience of the product.

Key varieties include:

| Gummy Type | Description | Target Audience | Key Characteristics |

| Gelatin-Based Gummies | Chewy texture, iconic designs like bears or worms. | Traditional candy lovers | Cost-effective, familiar texture, but faces demand for plant-based alternatives due to ethical concerns. |

| Pectin-Based Gummies | Plant-based gelling agent, firmer texture than gelatin. | Vegans, vegetarians | Offers a clean-label and ethical alternative, taps into the growing plant-based product market. |

| Agar-Based Gummies | Seaweed-based, providing a firm, resilient texture. | Vegan, gourmet markets | Quick-setting, ideal for detailed shapes and high-temperature environments, premium product appeal. |

.

3. Functional Gummies

Functional gummies include ingredients designed to provide health benefits beyond basic nutrition. These types are popular with millennials and health-conscious consumers.

Key varieties include:

| Gummy Type | Description | Target Audience | Key Characteristics |

| CBD Gummies | Combines wellness benefits with gummy format. | Millennials, Gen Z, wellness seekers | Popular for stress relief, relaxation, pain management. Compliance with regulations and precise dosing is crucial for manufacturers. |

| Vitamin Gummies | Infused with vitamins like C, D, B12 to meet daily nutritional needs. | Adults, children | Growing demand for immune support, energy boosts, and convenient nutrition. Appeals to health-conscious consumers seeking fun alternatives to pills. |

.

4. Dietary Gummies

Dietary gummies focus on meeting specific dietary needs, including sugar-free options and plant-based alternatives.

Key varieties include:

| Gummy Type | Description | Target Audience | Key Characteristics |

| Sugar-Free Gummies | Made with sugar substitutes like stevia or monk fruit. | Diabetics, low-carb dieters | Meets demand for healthier alternatives without sacrificing taste. Appeals to better-for-you snack markets. |

| Vegetarian/Vegan Gummies | Uses pectin or agar instead of animal-based gelatin. | Vegans, vegetarians | Perfect for consumers seeking ethical and sustainable products. Part of the growing plant-based diet movement and clean-label trends. |

.

.

5. Age-Specific Gummies

Age-specific gummies are formulated to meet the nutritional needs and preferences of different age groups, including children and adults. The shape, flavor, and ingredients are often tailored to suit each demographic.

Key varieties include:

| Gummy Type | Description | Target Audience | Key Characteristics |

| Kids' Gummies | Gummies formulated specifically for children, often in fun shapes like animals or cartoons. | Children | Focused on taste, fun shapes, and nutritional needs. Popular for vitamins or functional gummies for children. |

| Adult Gummies | Gummies that cater to the nutritional needs and preferences of adults, often with added supplements like CBD or vitamins. | Adults | Functional focus for immune support, wellness, and convenience. Often features minimalist shapes like cubes or discs for a professional appearance. |

.

What Are Gummies Made Of? Ingredients Behind Different Gummy Candies

Gummies candies come in a wide array of flavors, shapes, and purposes. However, their ingredients can be broadly categorized based on their primary function. Let's delve into the components that make up these delightful chewy treats.

| Ingredients for different gummies | ||

| Gummy candies: | Gelatin: This essential protein forms the chewy backbone of most gummy candies. Sugar: The primary sweetener, adding that familiar sweetness and helping to bind everything together. Corn syrup: Another sweetener that contributes to the texture and prevents sugar from crystallizing, keeping the gummies soft. Citric acid: A natural acid that balances the sweetness and provides a subtle tartness. Natural and artificial flavors: These create the diverse range of flavors we love in gummies, from classic fruits to more adventurous options. Food coloring: Natural or artificial colors are added to make gummies visually appealing and match their intended flavors. | |

| Edible gummies (Infused with CBD, THC, etc.): | Gelatin or pectin: These act as the glue that holds the gummy together, creating its signature chewy texture. Active ingredient (like CBD or THC): This is where the magic happens! It's the component that delivers the desired effect, whether it's relaxation, pain relief, or a little bit of euphoria. Sugar or sugar substitutes: Because what's a gummy without a touch of sweetness? These add flavor and make the experience more enjoyable. Natural flavors: These bring the fun! From fruity bursts to exotic blends, natural flavors make each gummy a tasty adventure. Citric acid: This multitasker not only adds a tangy kick but also helps keep the gummies fresh and safe to eat. | |

| Gummy vitamins: | Gelatin or pectin: These act as the glue that holds the gummy together, creating its signature chewy texture. Gelatin comes from animal sources, while pectin is plant-based, making it suitable for vegans. Vitamins and minerals: A variety of vitamins, such as C, D, E, and B, along with minerals like zinc, calcium, and magnesium, are often added to boost the nutritional value of gummies. Sugar or sugar substitutes: Sugar adds sweetness and enhances the flavor, but for those watching their sugar intake, alternatives like stevia or monk fruit can be used. Natural flavors: These provide the delicious taste that makes gummies so enjoyable. They can be derived from fruits, herbs, or other natural sources. Citric acid: This serves a dual purpose: it acts as a preservative to keep the gummies fresh and also adds a pleasant tangy flavor. | |

.

How Production Processes Define Gummy Edibles: From Starch Molding to Direct Depositing

The production method you choose significantly affects a gummy’s texture, appearance, and manufacturing efficiency. The two main methods are starch molding and direct depositing (also known as starchless or non-starch depositing), each suited for different gummy types.

1. Starch Mogul Molding: Best for Complex Shapes and Softer Textures

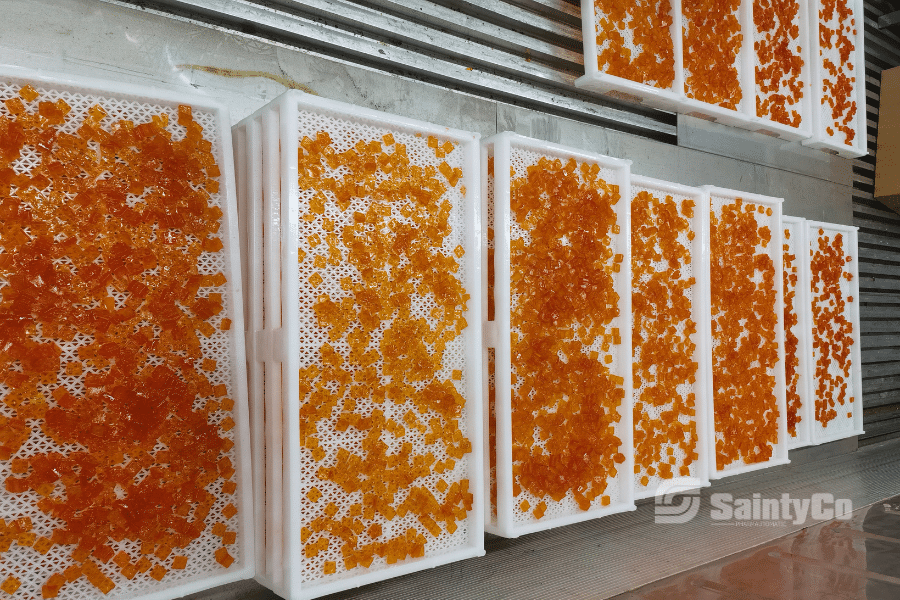

- Process: Gummy mixtures are deposited into trays filled with powdered starch, which absorbs moisture as the gummies cool and set. This results in a softer, more flexible texture.

- Best For: Ideal for intricate shapes (e.g., bears, worms, holiday-themed gummies) and softer textures.

- Challenges: Time-consuming, requires starch removal, and is less efficient for large-scale production.

.

.

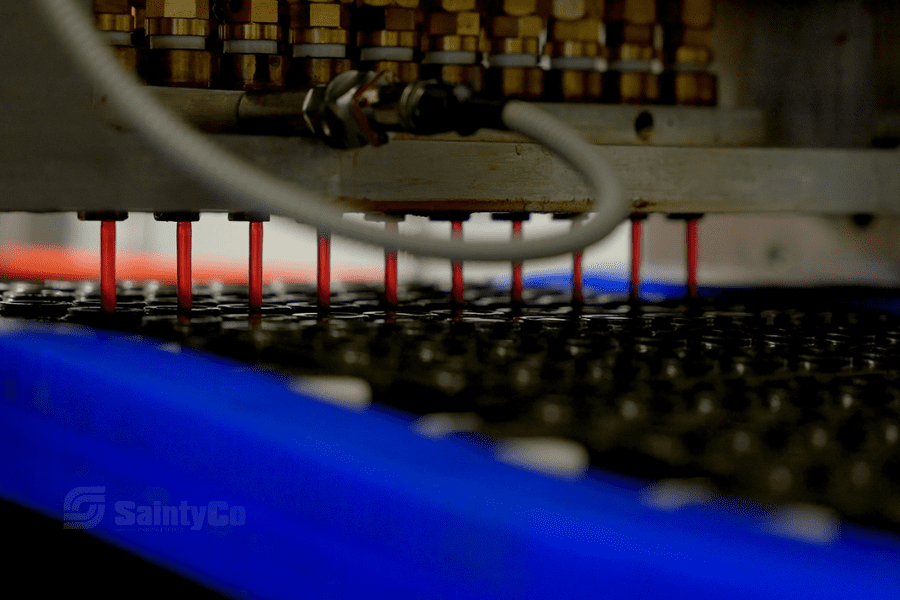

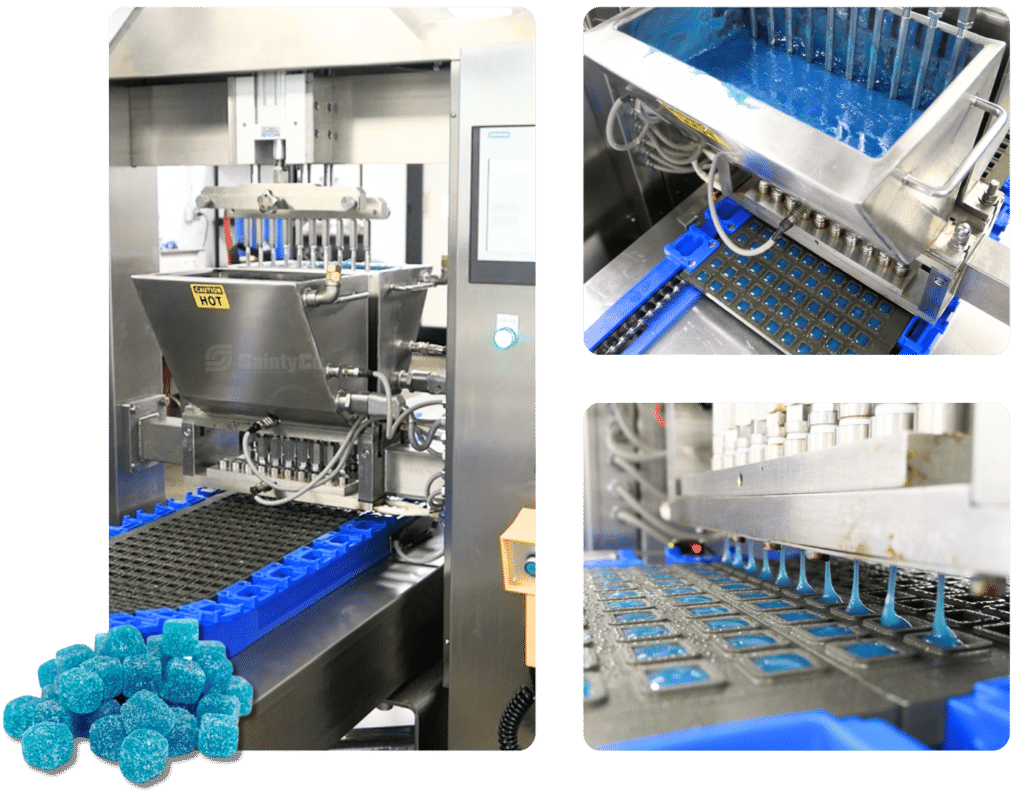

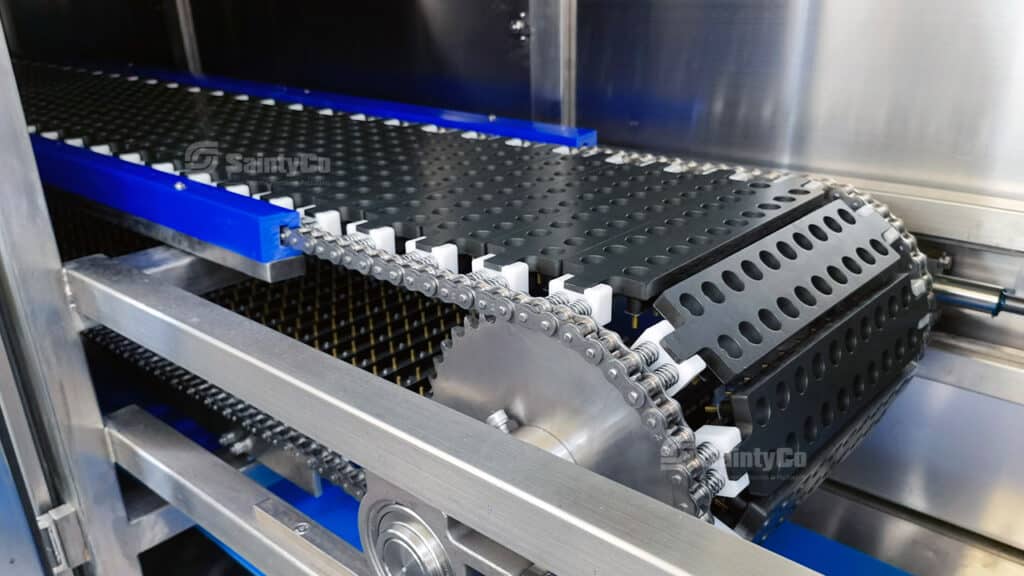

2. Direct Depositing (Starchless or Non-Starch Depositing): Ideal for High-Volume Functional Gummies

- Process: Gummy mixtures are deposited directly into silicone or metal molds without using starch. This method is faster and automated, producing firmer gummies with precise dosing.

- Best For: Suited for functional gummies (e.g., CBD or vitamin gummies) that require accurate dosing and uniform shapes.

- Advantages: More efficient, reduces labor costs, and produces a smooth finish. Excellent for large-scale production.

- Challenges: Results in firmer gummies, which may not appeal to those preferring softer textures.

.

.

Choosing the Right Method for Your Gummy Production

The choice between starch molding and direct depositing comes down to your product goals. If you want to produce gummies with intricate shapes or softer textures, starch molding is your go-to. However, if you need high-volume production, especially for functional gummies like vitamin or CBD gummies, direct depositing is the better option. This technique ensures consistency, dosing accuracy, and efficiency, making it ideal for businesses looking to scale production while maintaining product quality.

.

How to Make Gummy Candies (Step-by-step)

Producing gummies on a commercial scale requires precise steps to ensure consistent quality:

- Ingredient Preparation

Ingredients like gelatin, sweeteners, flavorings, and colors are measured according to the recipe. Gelatin is hydrated in cold water, while sugar (or substitutes) dissolves in water to form a sweet syrup, essential for texture and taste. - Cooking and Mixing

The hydrated gelatin and syrup are heated in a kettle under controlled conditions to achieve the perfect gelatinization. Flavorings and colors are added at specific points for even distribution. In some cases, vacuum processing removes air bubbles for a smoother texture. - Depositing or Molding

Automated machines fill molds with the gummy mixture. Starch molding (where starch forms the gummy shapes) is occasionally used in traditional methods. - Cooling and Setting

The filled molds pass through cooling tunnels to solidify the gummies. In starch molding, molds are placed in a controlled environment to set under specific humidity and temperature. - Demolding

Automated systems gently release the gummies from molds. For starch-molded gummies, sieving separates them from the starch, which is reused.

Optional Steps:

Additional steps like oiling to prevent sticking, sugar coating or sanding for texture, and packaging ensure product freshness and appeal.

Through specialized equipment and precise methods, commercial gummy production consistently delivers high-quality, appealing products to consumers.

.

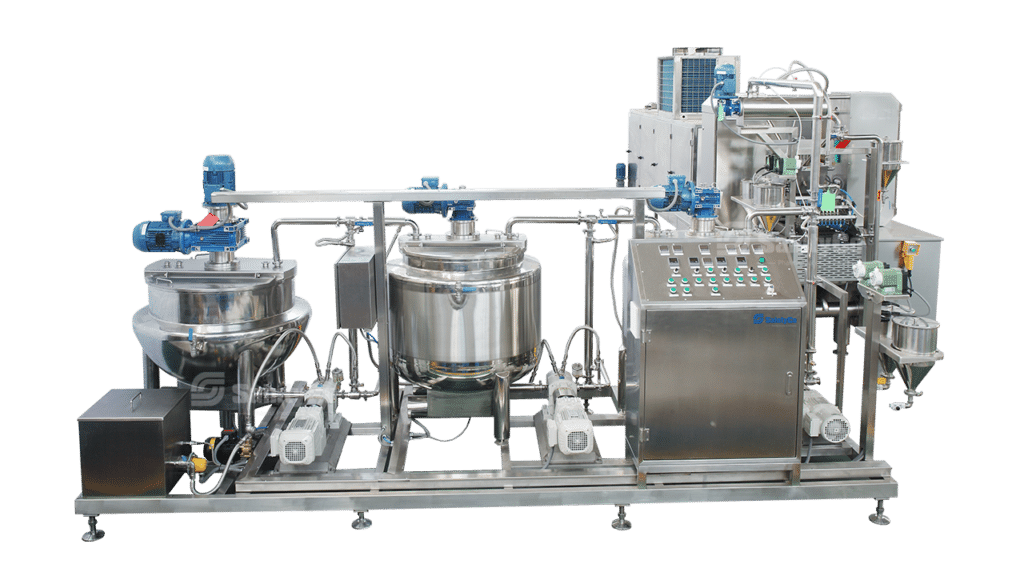

What Equipment Do You Need to Make Gummy Candies?

Producing high-quality gummies—whether sugar-free, CBD-infused, or vegan—requires the right equipment to ensure consistency, scalability, and compliance. Here's a breakdown of essential equipment for different types of gummy production:

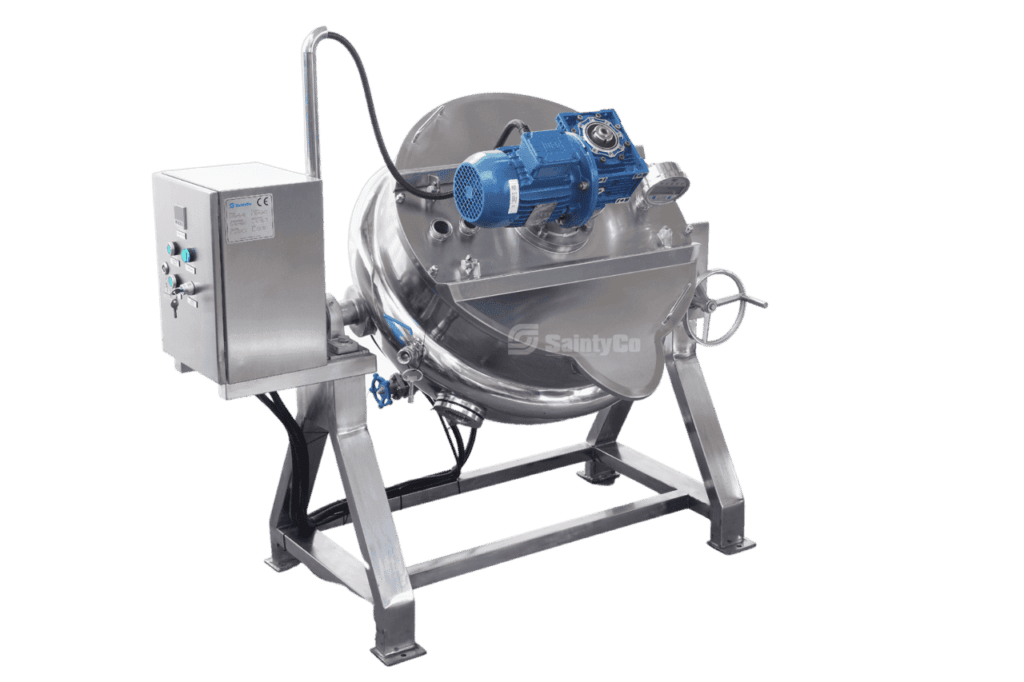

1. Mixing and Cooking Equipment: Ensuring Consistency and Quality

Purpose: Mixing and cooking are critical for achieving the right texture, flavor, and ingredient uniformity. Whether for traditional fruit gummies, CBD-infused products, or sugar-free formulations, the equipment used at this stage plays a vital role.

- Small-Scale Production:

- Batch mixers paired with manual or semi-automated kettles.

- Ideal for artisan or specialty gummies (e.g., CBD gummies) that require tighter control over smaller batches.

- For complex recipes like vegan gummies, batch mixing might lack the precision needed for consistent scaling.

.

- Large-Scale Production:

- Continuous mixers and automated cooking systems for precise blending and temperature control across larger volumes.

- This setup is essential for handling complex formulations (e.g., sugar-free or CBD gummies) where the risk of crystallization or heat damage is higher.

.

Gummy-Type Specific Insights:

- Sugar-Free Gummies:

- Challenges: Thicker mixtures due to sugar substitutes like stevia or erythritol are prone to crystallization if not properly handled.

- Solution: Continuous mixers manage viscosity, while automated kettles prevent issues like grittiness or crystallization.

- Business Strategy: Investing in specialized equipment for sugar substitutes ensures consistent texture and taste, giving sugar-free gummies the same appeal as traditional versions, while capturing the health-conscious market.

- CBD Gummies:

- Challenges: CBD is heat-sensitive and requires precise temperature control to avoid degrading its potency.

- Solution: Automated kettles with real-time temperature monitoring and continuous mixers ensure even CBD distribution without potency loss.

- Business Strategy: Consistent potency builds consumer trust, ensures regulatory compliance, and helps avoid costly recalls. Automation in this area is key for scaling in the growing CBD market.

- Vegan Gummies (Pectin-Based):

- Challenges: Pectin requires higher temperatures and fast thickening, making precise temperature and timing crucial.

- Solution: Continuous mixers and automated systems prevent overcooking and tough textures.

- Business Strategy: With the rising demand for plant-based products, investing in premium equipment ensures that vegan gummies maintain consistent quality, helping manufacturers stand out in the vegan and health-conscious markets.

.

Advanced kitchen technology is necessary for blending ingredients, including gelatin, flavorings, sweeteners, and colors, to create a smooth gummy base. The GummyGenix by SaintyCo industrial-grade mixers ensure that all components are evenly distributed and prepared for the next step. This unit handles your gummy ingredients gently to guarantee accurate recipes and the best texture.

.

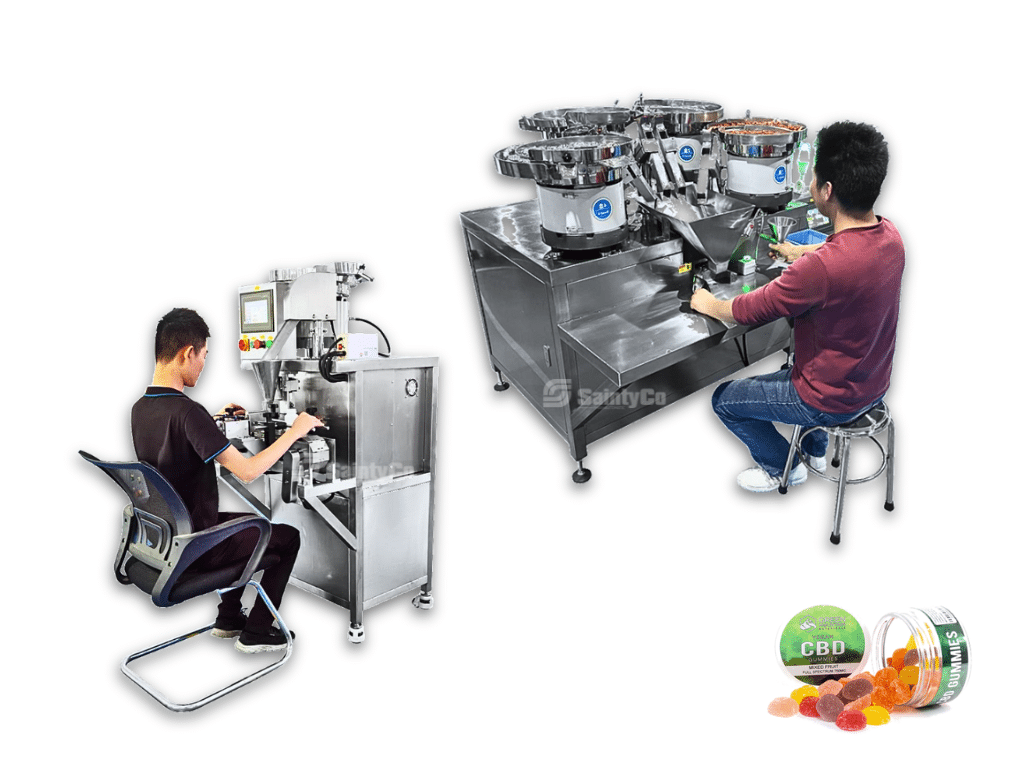

2. Depositing and Molding: Precision for High-Quality Gummies

The depositing and molding stages are critical for ensuring that gummies are shaped correctly and that active ingredients (like CBD or vitamins) are dosed accurately. Precision is particularly crucial for functional gummies, where small dosing errors can lead to compliance issues and consumer mistrust.

- Small-Scale Production

- Semi-automatic depositors are sufficient for boutique production or small runs of specialized gummies (e.g., CBD gummies).

- Manual systems often struggle with thicker formulations, like sugar-free or vegan gummies, due to challenges in maintaining dosing accuracy.

.

- Large-Scale Production

- Automated depositing systems ensure consistent dosing and uniform shapes across large batches.

- These systems are designed to handle a variety of formulations, including pectin-based vegan gummies and sugar-free gummies, where viscosity control is critical.

.

Gummy-Type Specific Insights

- Sugar-Free Gummies:

- Challenges: Thicker formulations (from sugar substitutes like stevia or erythritol) can cause air pockets and inconsistent filling.

- Solution: Automated depositors handle the unique flow of these substitutes, ensuring proper filling and shape retention.

- Business Strategy: Automation prevents waste from failed batches and ensures that sugar-free gummies maintain a soft texture, providing a competitive edge in the health-conscious market.

- CBD Gummies:

- Challenges: Precise dosing is critical to ensure each gummy has the correct CBD content and meets regulatory standards.

- Solution: Automated depositors guarantee accurate dosing, preventing recalls due to inconsistencies.

- Business Strategy: Consistent dosing builds consumer trust and ensures compliance, reducing risks and protecting brand integrity.

- Vegan Gummies (Pectin-Based):

- Challenges: Pectin-based mixtures are thicker and slower to flow than gelatin, requiring specialized depositors for even distribution and preventing air bubbles.

- Solution: Automated equipment ensures smooth depositing without overfilling, maintaining quality.

- Business Strategy: Investing in automated systems enables manufacturers to scale vegan gummies while maintaining high quality, capturing the growing vegan market.

.

3. Cooling and Drying: Ensuring Gummy Texture and Shelf Stability

Proper cooling and drying are essential for gummies to retain their texture, shape, and shelf stability. This is especially critical for formulations like sugar-free gummies, which are prone to crystallization, or CBD gummies, where prolonged heat exposure can degrade active ingredients.

- Small-Scale Production

- Manual drying rooms allow flexibility but can lead to inconsistent cooling and longer production times.

- For sensitive products like CBD gummies, manual cooling can cause uneven ingredient distribution or potency loss if not carefully monitored.

.

- Large-Scale Production

- Automated cooling tunnels offer consistent, rapid cooling, ensuring proper gummy setting.

- Particularly useful for pectin-based vegan gummies, which need to cool quickly to avoid becoming too firm, and CBD gummies, where fast cooling preserves CBD potency.

.

Gummy-Type Specific Insights

- Sugar-Free Gummies:

- Challenges: Prone to crystallization during cooling if temperatures aren’t tightly controlled.

- Solution: Automated cooling tunnels provide a stable environment, preventing crystallization and maintaining softness.

- Business Strategy: Precise cooling ensures sugar-free gummies maintain a texture comparable to traditional sugary versions, meeting consumer expectations for texture and shelf stability.

- CBD Gummies:

- Challenges: Rapid cooling is critical to preserve the potency of the CBD.

- Solution: Automated cooling tunnels prevent heat degradation and ensure quick, consistent cooling.

- Business Strategy: Maintaining product consistency through rapid cooling builds consumer trust and strengthens brand loyalty, ensuring that the gummies deliver promised effects.

- Vegan Gummies (Pectin-Based):

- Challenges: Higher setting temperatures require precise cooling to maintain the ideal texture.

- Solution: Automated systems ensure even cooling, preventing over-setting and preserving a gelatin-like texture.

- Business Strategy: Ensuring proper texture and shape enables manufacturers to meet growing demand for high-quality vegan products, positioning the brand as a leader in the plant-based market.

.

4. Demolding Systems: Ensuring Clean and Efficient Gummy Release

Demolding ensures that gummies are released from molds cleanly without compromising shape, texture, or dosing accuracy. This process is especially critical for sensitive formulations like sugar-free, CBD, and vegan gummies, which are more prone to sticking or breakage.

- Small-Scale Production

- Pneumatic demolders are ideal for small-batch or artisanal production. They use compressed air to gently release gummies, making them more efficient than manual processes.

- However, sticky formulations like vegan gummies made from pectin can pose challenges due to higher mold adhesion.

.

- Large-Scale Production

- Fully automated demolding systems are essential for maintaining high throughput and consistent product quality.

- These systems often include air-puff release or non-stick molds to prevent sticking and ensure quick, damage-free gummy release, even for trickier formulations like sugar-free and CBD gummies.

.

Specific Gummy-Type Insights:

- Sugar-Free Gummies

- Challenges: Sugar substitutes like xylitol or erythritol can make gummies brittle or prone to sticking to molds. These substitutes also lead to harder textures, increasing the risk of breakage during demolding.

- Solution: Pneumatic demolders for small-scale production ensure a gentle release, while automated systems with non-stick molds are essential for preventing crystallization and maintaining consistent shapes in large-scale operations.

- Business Strategy: Investing in automated demolding technology reduces breakage and preserves product appearance, which is critical in the health-conscious market. This also lowers costs by reducing defective products.

- CBD Gummies

- Challenges: CBD gummies often contain oily active ingredients, making them stickier and prone to deformation during manual or semi-automatic demolding.

- Solution: Pneumatic demolders for small batches ensure gentle removal, while silicone molds with air-puff systems prevent sticking and ensure accurate dosing on fully automated lines.

- Business Strategy: Optimizing the demolding process ensures consistent dosing and product quality, helping avoid legal risks and product recalls while building consumer trust.

- Vegan Gummies (Pectin-Based)

- Challenges: Pectin-based gummies tend to be firmer and more likely to stick to molds compared to gelatin gummies, especially if cooling and demolding aren't timed properly.

- Solution: Pneumatic demolders work for small batches, while fully automated systems with precise timing controls and temperature adjustments prevent sticking in large-scale production.

- Business Strategy: Automated systems ensure consistent product quality, crucial for the premium market, where consumers expect perfect shapes and a high-quality finish.

.

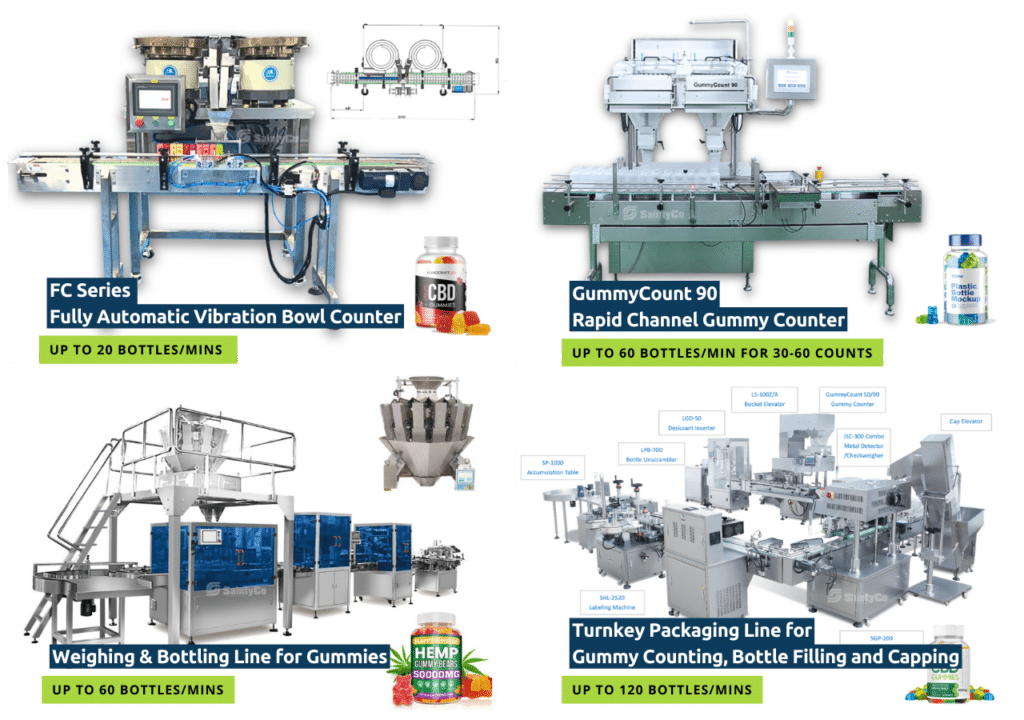

5. Packaging: Protecting Product Quality and Shelf Life

Packaging is the final step in gummy production and is crucial for preserving freshness, potency, and shelf life. For sensitive ingredients like CBD or sugar-free formulations, packaging must protect against moisture, light, and air to maintain quality.

- Manual and Semi-Automatic Packaging (Small Scale)

- Semi-automatic systems offer flexibility for boutique products or limited editions, but may struggle with ensuring consistent, airtight seals, especially for products like CBD gummies that require light and oxygen protection.

- These systems are more labor-intensive and less efficient for large volumes.

.

- Fully Automated Packaging Systems (Large Scale)

- Automated packaging lines are essential for large-scale production, ensuring each gummy is packed in airtight, tamper-proof containers.

- Vital for products like CBD gummies or probiotic-enriched gummies, where exposure to air or moisture can degrade active ingredients.

- Ensures high-quality sealing, improving product freshness and shelf stability across larger production runs.

.

Specific Gummy-Type Insights:

- Sugar-Free Gummies

- Challenges: Moisture-sensitive, prone to texture loss if not sealed properly.

- Solution: Automated packaging lines provide moisture-resistant, airtight sealing to preserve quality and texture.

- Business Strategy: Airtight packaging keeps sugar-free gummies chewy and appealing, ensuring consumer satisfaction in the diet-conscious market.

- CBD Gummies

- Challenges: Require light-blocking and airtight packaging to prevent CBD degradation.

- Solution: Automated systems provide proper sealing to maintain CBD potency over time.

- Business Strategy: Proper packaging guarantees consistency and potency, giving manufacturers a competitive edge in the growing CBD wellness market.

- Vegan Gummies (Pectin-Based)

- Challenges: Often marketed as premium products, they benefit from sustainable packaging (e.g., biodegradable or recyclable materials).

- Solution: Eco-friendly packaging appeals to the eco-conscious segment of the plant-based consumer base.

- Business Strategy: Investing in sustainable packaging boosts brand image and taps into the growing eco-conscious market.

.

Packaging equipment ensures the gummies are sealed and protected for freshness. From basic bagging machines to advanced, automated packaging systems, GummyGenix has it all. They make packaging systems that fill, seal, and print labels automatically. This is a crucial step for presenting your gummies appealingly and professionally.

.

Order the Best Gummy Production Equipment from GummyGenix

GummyGenix is your one-stop shop for all your gummy production equipment needs, from single units to complete production lines. We offer everything you need to streamline your manufacturing process with precision and efficiency. Our equipment is tailored to your brand, ensuring seamless integration with your production line while offering customization options to meet your specific needs.

Contact GummyGenix today to discuss your gummy manufacturing needs and get started on creating your delicious treats!

.

Conclusion

The world of gummies is evolving, with new flavors, dietary options, and health benefits continuing to attract consumers. As the demand for diverse gummy types grows, manufacturers must stay ahead by investing in the right equipment and refining their production processes. Whether you’re a gummy enthusiast or a large-scale producer, the future of gummies is bright—and full of possibilities.

.

FAQs

1. Are gummies healthy?

Regarding health, the downside of gummy consumption may outweigh the benefits. According to a study by Scripps, gummies owe their sweetness to sugar or sugar substitutes. They contain one or more sugar grams per gummy; if you take several gummies daily, the sugar can build up. In fact, Dr. Chappell compares it to like taking a sugar pill 365 days a year. Too much sugar may lead to chronic diseases like diabetes and obesity. Even sugar-free gummies aren’t safe because they contain citric acid, which wears down a person’s tooth enamel. Therefore, you should watch your gummy intake and take gummy vitamins per the recommended dose.

2. What differentiates regular gummies from sour gummies?

Both regular and sour gummies are made using a similar basic process. Their main difference is that sour gummies are coated with a mix of sugar and citric acid, giving them a tangy, tart bite. Sour gummies also tend to have a more intense flavor. They are often a favorite for those who enjoy bold, puckering tastes.

3. Are vitamin gummies a good way to get my daily vitamins?

This depends on many factors. According to a study by Healthline, gummy vitamins offer a more pleasing taste and are easier to take than regular vitamin pills. This makes them a good option for taking vitamins, especially for kids. However, the vitamin present in gummies is typically less than that in chewable vitamins. Also, vitamin gummies tend to have high sugar content, and sometimes their dosage is unreliable. Therefore, they may not be the best option, but ultimately, you are better off taking gummy vitamins than not consuming vitamins at all.

4. What are the latest trends in the gummy candy industry?

The gummy industry is transforming rapidly. According to a recent study, the sector registered a 4% rise in new gummy candy launches in Europe over the last five years. Recent trends are functional gummies and clean label claims. Functional gummies include vegan options, low-sugar gummies, CBD-infused gummies, and supplements. Most gummy manufacturers are constantly innovating to create new and unique flavors.

5. How long do gummies last?

Gummies generally have a shelf life of 6 to 12 months when stored properly. Factors such as ingredients, storage conditions, and packaging will influence how long they stay fresh. Gummies that contain preservatives or sugar substitutes may have a slightly different shelf life. Always check the packaging for expiration dates, and ensure gummies are stored in cool, dry environments away from direct sunlight to maintain their texture and flavor.

6. How should gummies be stored?

For optimal freshness, gummies should be stored in airtight containers in a cool, dry place. Excess moisture can cause gummies to become sticky, while excessive heat can make them melt or lose their shape. It’s also important to avoid placing gummies near strong-smelling foods or substances, as they can absorb odors easily.

7. Why are my gummies becoming sticky?

If your gummies are becoming sticky, it could be due to improper storage or environmental factors like humidity. To prevent this, store gummies in an airtight container in a cool and dry environment. For extra protection, you can dust the gummies lightly with cornstarch or coat them with a thin layer of sugar or oil to keep them from sticking together.

8. How do I prevent gummies from hardening over time?

Gummies may harden if they are exposed to air for too long or if they lose moisture. To prevent this, store them in airtight containers or sealed packaging to maintain moisture levels. Additionally, if gummies become too hard, you can try softening them by placing them in a sealed container with a damp paper towel overnight—the moisture from the paper towel may help restore some of their softness.