Fibre Gummies Production: How to Perfect Texture and Quality?

Fibre gummies are a growing segment in the health supplement market. To manufacture them successfully, focus on key aspects such as ingredient selection (like inulin and pectin), precise temperature control, effective moulding techniques, and appropriate packaging solutions. Each stage of production presents unique challenges that can be optimized for efficiency and quality. Proper management of moisture levels during drying and cooling is crucial for achieving the desired texture. Additionally, adhering to regulatory standards ensures product safety and builds consumer trust. By understanding these factors, manufacturers can create fibre gummies that are not only tasty but also beneficial for health.

Packaging Gummies: Can Standard Machines Handle It or Require Upgrading?

Packaging gummies using standard confectionery machines is possible but requires modifications to address their unique challenges like stickiness and moisture sensitivity. While these machines can be adapted, investing in specialized gummy packaging equipment is often more efficient. Specialized machines feature non-stick materials, precise environmental controls, and advanced detection systems that enhance product quality and consistency. They also comply with hygiene standards essential for food safety. This blog explores the considerations for using standard machinery versus specialized solutions in gummy production, emphasizing the importance of accuracy in packaging to maintain customer satisfaction and brand reputation.

Gummy Manufacturing Process: What Are the 7 Critical Factors to Monitor?

For new gummy manufacturers, success hinges on monitoring six essential factors: temperature control for texture and shelf life; ingredient consistency for uniformity; pH levels to prevent spoilage; water activity to inhibit microbial growth; humidity management for optimal production conditions; and packaging integrity to safeguard against contamination. Each factor plays a vital role in ensuring product quality and compliance with industry standards. By focusing on these elements, manufacturers can enhance their production processes and meet market expectations effectively. This guide provides insights into practical strategies for maintaining these critical parameters throughout the manufacturing process.

What’s the Difference Between Gummy Bears and Jelly Babies?

Jelly Babies and gummy bears are popular candies with distinct textures influenced by their ingredients. Jelly Babies use pectin or starch for a soft feel, while gummy bears rely on gelatin for chewiness. Their production processes also vary, with Jelly Babies requiring aeration and rounded molds, whereas gummy bears need precise temperature control and intricate molds. Understanding these differences helps manufacturers choose suitable equipment for optimal results. As consumer preferences shift towards healthier options, innovations in candy production allow for the creation of vegan and sugar-free varieties. This article explores the unique characteristics of both candies, providing insights into their production techniques and market trends.

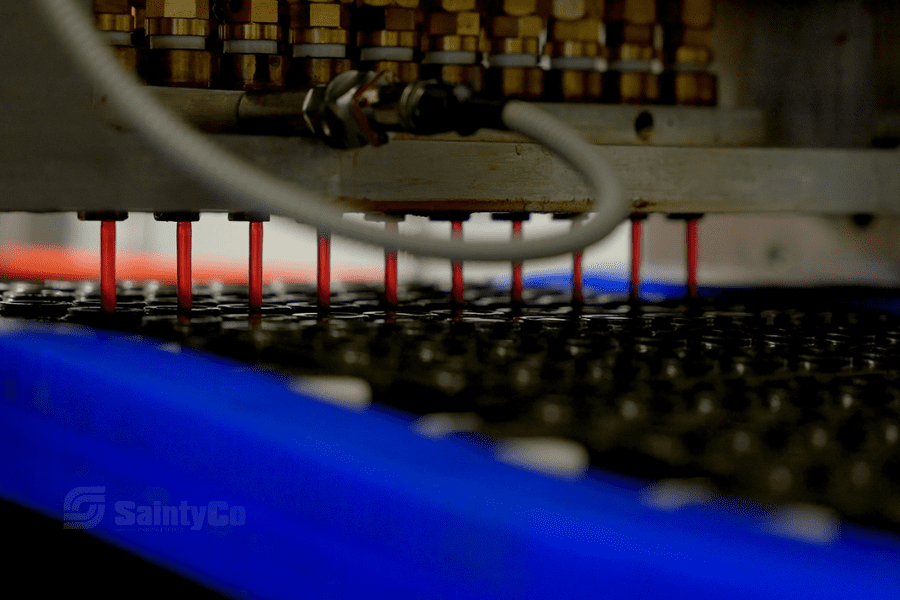

Flood & Scrape vs. Gummy-Making Machines: Which Is Best for Your Production?

Gummy-making machines offer significant advantages over the traditional Flood & Scrape method in gummy production. These machines provide enhanced efficiency, consistency, and scalability, making them ideal for expanding businesses. By minimizing waste through precision dosing and automated cleaning systems, they ensure higher quality and more reliable output. Automation also allows for better control of ingredient handling and environmental factors, reducing human error and improving product uniformity. As demand for gummies grows, investing in modern machinery not only supports sustainability but also aligns with regulatory compliance needs in industries like nutraceuticals and CBD. Ultimately, while initial costs may be higher, the long-term benefits of reduced labor expenses and increased production capacity make gummy machines a cost-effective choice for manufacturers aiming to scale their operations effectively.

Top 6 Gummy Trends for 2025: What Manufacturers Must Know?

The gummy candy market is experiencing significant growth driven by key trends such as the rise of vegan gummies, social media-driven designs, and health-conscious formulations. Consumers are increasingly seeking plant-based options that align with ethical values and dietary preferences. Social media platforms like TikTok and Instagram are influencing gummy designs, pushing manufacturers to create visually appealing products that engage younger audiences. Additionally, the demand for sugar-free and functional gummies is on the rise as health-conscious consumers look for tasty alternatives that offer nutritional benefits. To seize these opportunities, manufacturers should invest in advanced production technologies tailored for pectin-based gummies and explore innovative designs that cater to evolving consumer preferences.

Jelly vs Gummy: Which Candy Best Captures Your Market?

Choosing between jelly and gummy candies can significantly influence your confectionery business’s success. Jelly candies are soft and often favored by health-conscious consumers due to vegan options, while gummy candies offer a chewier texture that appeals to a wider audience with fun shapes. Understanding the differences in texture, ingredients, and production methods is crucial for making an informed decision. This article explores these aspects in detail, helping businesses determine which candy type aligns best with their market goals. Additionally, it discusses how advanced machinery can efficiently produce both types of candies while meeting diverse consumer preferences.

Pharma Grade vs. Confectionery Gummy Machines: What’s the Difference?

This article compares pharma-grade and confectionery-grade gummy production machines, highlighting differences in regulatory compliance, material integrity, cleaning protocols, precision, and cost to guide informed purchasing decisions.

What Are the Expert Tips for Making CBD Gummies?

Learn expert tips for making high-quality CBD gummies at home. Discover the importance of choosing the right CBD extract, ingredient selection, dosage precision, and essential equipment for successful production.

Should You Invest in Gummy Manufacturing Equipment Now?

The gummy market is booming, especially in health and wellness sectors. With such growth, it’s essential to consider if now is the right time to invest in gummy manufacturing equipment. This article dives deep into market trends, automation benefits, compliance considerations, and technological advancements that can impact your decision to invest.