Uncover the key elements in selecting the perfect gummy molds for your production line, whether you're an experienced manufacturer or just getting started.

Choosing the best gummy molds requires consideration of material, mold design, and ease of cleaning. Silicone gummy molds are favored for their flexibility and non-stick properties, while metal molds are valued for their durability and heat resistance. The right choice depends on your specific production needs.

Let's explore the details of gummy mold materials and maintenance tips to keep your production running smoothly.

Exploring Different Gummy Molds

When choosing gummy molds for your production line, it's crucial to consider both material and design. Here are the common types of gummy molds and their characteristics:

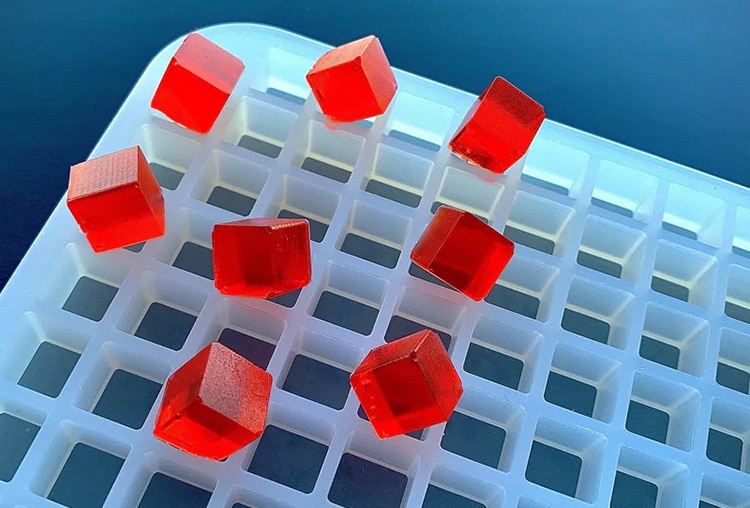

1. Silicone Gummy Molds

These are favored for their flexibility, durability, and non-stick properties. Typically used with manual depositing systems, commercial-grade silicone ensures a high-quality product capable of withstanding extensive use. These molds allow for easy removal of gummies without damage and can handle various temperatures throughout the manufacturing process.

.

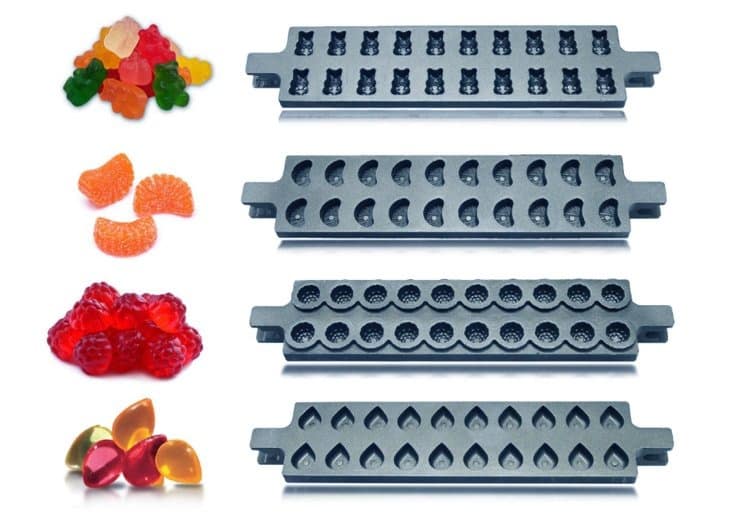

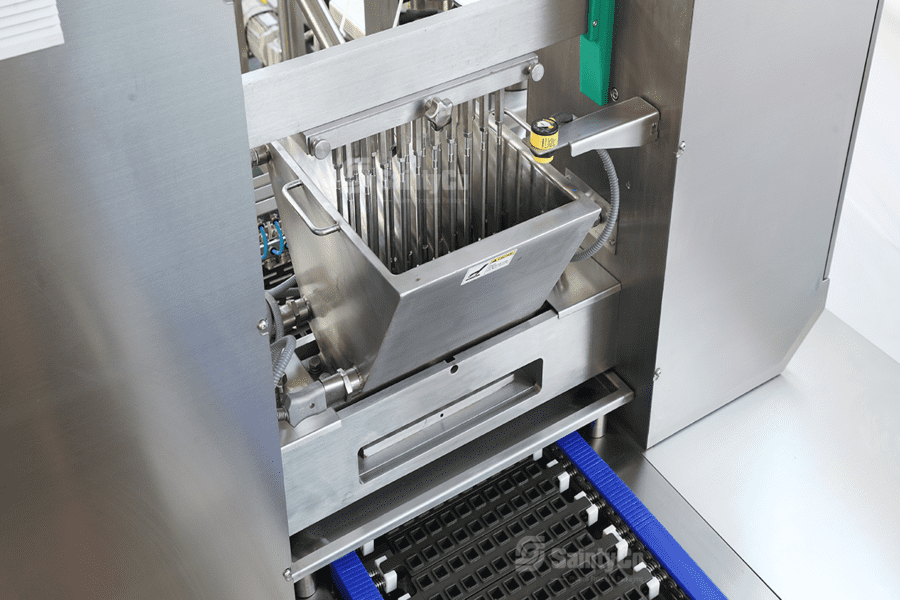

2. Teflon Aluminum Molds for Gummy Bears

The new standard for automatic gummy depositing molds, these are made from aluminum coated with Teflon to prevent sticking and simplify the demolding process. Teflon aluminum molds enhance production efficiency and ease of cleaning.

.

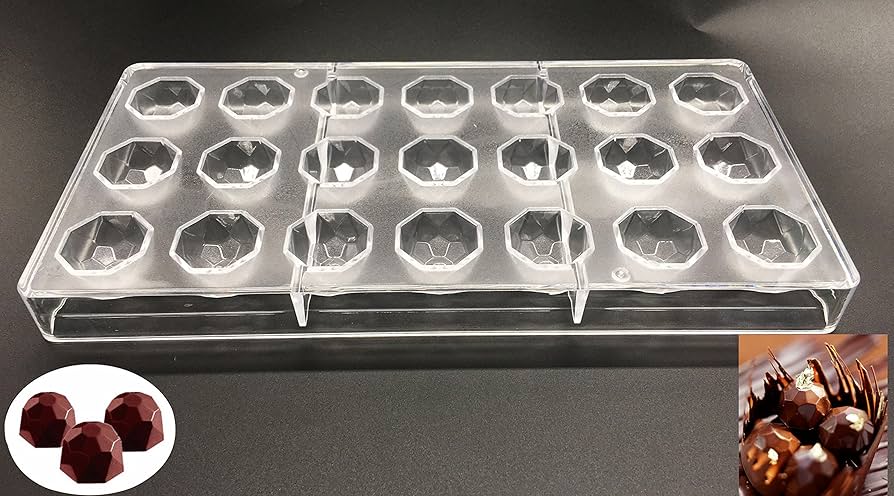

3. Polycarbonate Molds for Gummies and Cholocates

Renowned for their strength and clarity, polycarbonate molds resist high temperatures and can endure repeated use without warping or flexing. They offer excellent durability and maintain their shape over time.

.

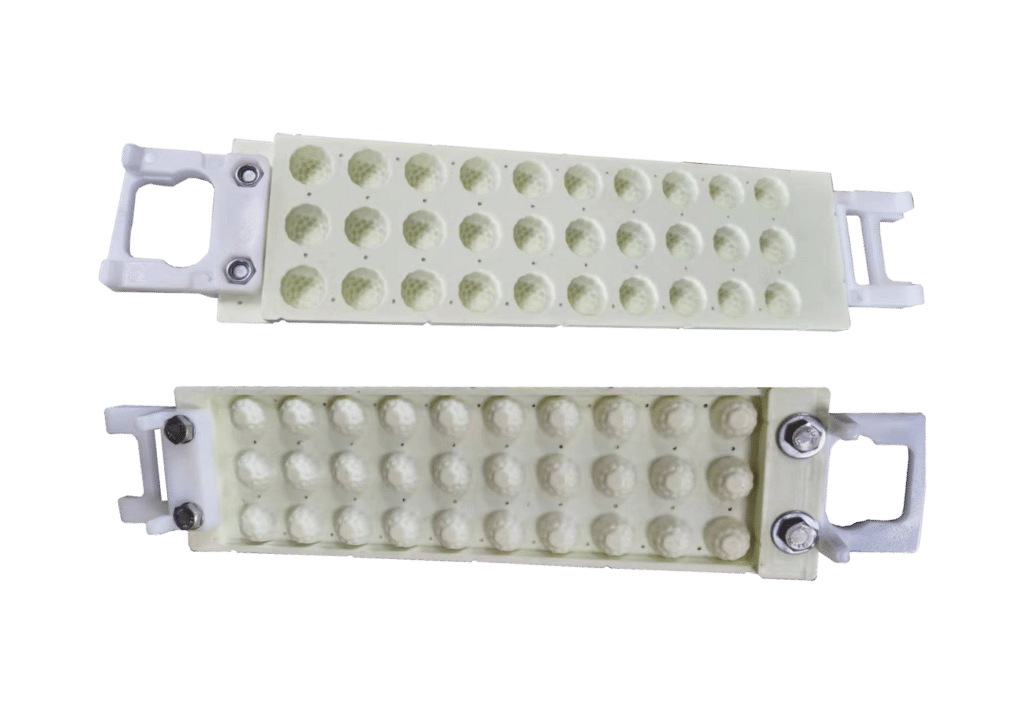

4. Plastic Molds for Gummy Candies

White-colored plastic molds provide visibility into the consistency and thickness of the gummies. Their flexibility allows for easy removal of softer candies without distortion and offers excellent heat resistance, enduring temperatures up to 350°C.

.

Here is a comparison table summarizing the key characteristics of each mold type:

| Aspect | Silicone Gummy Molds | Teflon Aluminum Molds | Polycarbonate Molds | Plastic Molds |

| Material | High-quality commercial-grade silicone | Aluminum with Teflon coating | High-strength polycarbonate | White-colored food-grade plastic |

| Flexibility | High - Easily bends and flexes | Low - Rigid and sturdy | Low - Rigid and maintains shape | Medium - Some flexibility for easy removal |

| Heat Resistance | Medium - Can withstand typical manufacturing temperatures | High - Excellent heat conduction | High - Resistant to high temperatures | High - Withstands up to 350°C |

| Durability | Medium - Durable with proper care | High - Long-lasting and sturdy | High - Very durable and long-lasting | Medium - Good durability with regular use |

| Ease of Cleaning | High - Non-stick and easy to clean | High - Teflon coating simplifies cleaning | Medium - Requires more effort to clean | Medium - Easy to clean but may require more effort for stubborn residues |

| Ease of Demolding | High - Non-stick properties ensure easy removal | High - Teflon coating prevents sticking | Medium - May require some effort | High - Flexibility aids in easy removal |

| Best For | Manual depositing, intricate and detailed designs | Automatic depositing, high-volume production | High-frequency use, maintaining precise shapes | Visibility during production, softer candies |

| Cost | Medium | High | High | Low to Medium |

| Common Applications | Small to medium-scale production, custom shapes | Large-scale production, standard shapes | Large-scale production, high-detail shapes | Small-scale production, custom and soft shapes |

| Typical Use Cases | Gummy bears, worms, detailed candy shapes | High-volume gummy production lines | High-detail candies and gummies | Custom shapes, detailed inspections during production |

| Advantages | Flexible, easy to use, various designs available | Durable, efficient heat distribution | Very strong, maintains shape well | Visible consistency, good for softer candies |

| Disadvantages | Can wear out faster, limited heat resistance | Higher cost, rigid | Requires careful handling, higher cost | Less durable, more effort in cleaning |

95% of SaintyCo's clients opt for metal molds in their semi- or fully automated gummy manufacturing equipment due to their durability and efficiency.

.

Practical Tips and Criteria for Choosing the Best Gummy Molds

When it comes to selecting the ideal gummy molds for your production needs, there are several key factors to consider. Here's a guide to help you make the best choice:

1. Material of the Molds

The material of the mold is crucial as it affects the quality and safety of the gummies. Common materials include:

- Silicone: Flexible, non-stick, and easy to clean. Ideal for home use.

- Polycarbonate: Durable and provides a professional finish. Suitable for commercial use.

- Metal: Typically used for industrial production due to its durability and ability to withstand high temperatures.

.

2. Size and Shape

Choose molds that match the desired size and shape of your gummies. Consider molds that offer versatility with multiple cavities and shapes to meet varying consumer preferences.

.

3. Ease of Use and Cleaning

Opt for molds that are easy to fill and release gummies without sticking. Non-stick materials like silicone are particularly beneficial. Additionally, ensure the molds are dishwasher-safe or easy to hand wash.

.

4. Temperature Resistance

Select molds that can withstand the temperatures involved in gummy production, especially if you plan to use them in ovens or freezers. Silicone and polycarbonate molds generally have high-temperature resistance.

.

5. Certifications and Safety Standards

Ensure the molds are certified for food safety by relevant authorities, such as FDA approval or BPA-free certification. This guarantees the molds are safe for producing consumable gummies.

.

6. Cost and Availability

While it’s essential to invest in high-quality molds, consider your budget and their availability. Compare prices and read reviews to ensure you are getting good value for your investment.

.

7. Durability

For commercial and industrial use, the durability of the molds is a significant consideration. Choose materials that can withstand frequent use without degrading over time.

By considering these factors, you can select the best gummy molds to meet your production requirements and ensure a high-quality end product.

.

.

Why You Need High-Quality Gummy Candy Molds

Using high-quality gummy candy molds is vital for ensuring consistency, quality, and safety across various sectors including confectionery, legalized cannabis, and supplements. For those using SaintyCo's gummy production lines, these molds are designed for seamless integration, ensuring optimal performance and product quality.

Confectionery Sector

- Consistent Shape and Size: Essential for maintaining brand identity and customer satisfaction.

- High Production Efficiency: Durable molds withstand the demands of high-volume production.

- Product Safety: Food-grade materials prevent contamination, ensuring candy safety.

.

Legalized Cannabis Sector

- Precise Dosing: Guarantees each gummy has an accurate amount of active ingredients.

- Compliance: Meets regulatory standards for safety and hygiene.

- Brand Differentiation: Custom molds allow for unique shapes that distinguish products in a competitive market.

.

Supplement Sector

- Product Integrity: Ensures active ingredients are evenly distributed and maintained.

- Consumer Trust: Consistent, high-quality products build consumer confidence.

- Regulatory Compliance: Molds meet stringent health and safety standards.

.

.

How to Keep Gummies from Sticking to Silicone Gummy Molds

Commercial-grade gummy molds often have a Teflon coating to prevent sticking. Before pouring the gummy mixture, ensure the molds are chilled and sprayed with a food-safe oil like MCT or sunflower oil to add extra slickness. This preparation helps in easy release and maintains the gummies' quality.

.

Do I Need to Spray Silicone Molds for Gummies?

It is recommended not to use nonstick sprays on silicone gummy molds. The propellants in these sprays can leave a residue that builds up over time, making the molds sticky and less effective. Instead, use a food-safe oil spray or ensure the molds are properly prepared as mentioned above.

.

Preventing Mold on Gummies and Gummy Vitamins

A common concern in gummy production is mold. Gummies can mold if not stored properly or if there are issues with ingredients or production processes. Maintaining proper hygiene standards and storage conditions is crucial to prevent mold on gummies. SaintyCo's production lines and molds are designed to minimize contamination risks, ensuring high-quality products.

Mold on gummy vitamins can significantly affect product safety and consumer trust. Using high-quality molds and maintaining strict production protocols can help prevent this issue. SaintyCo's molds and production lines are optimized for creating safe, high-quality gummy vitamins.

.

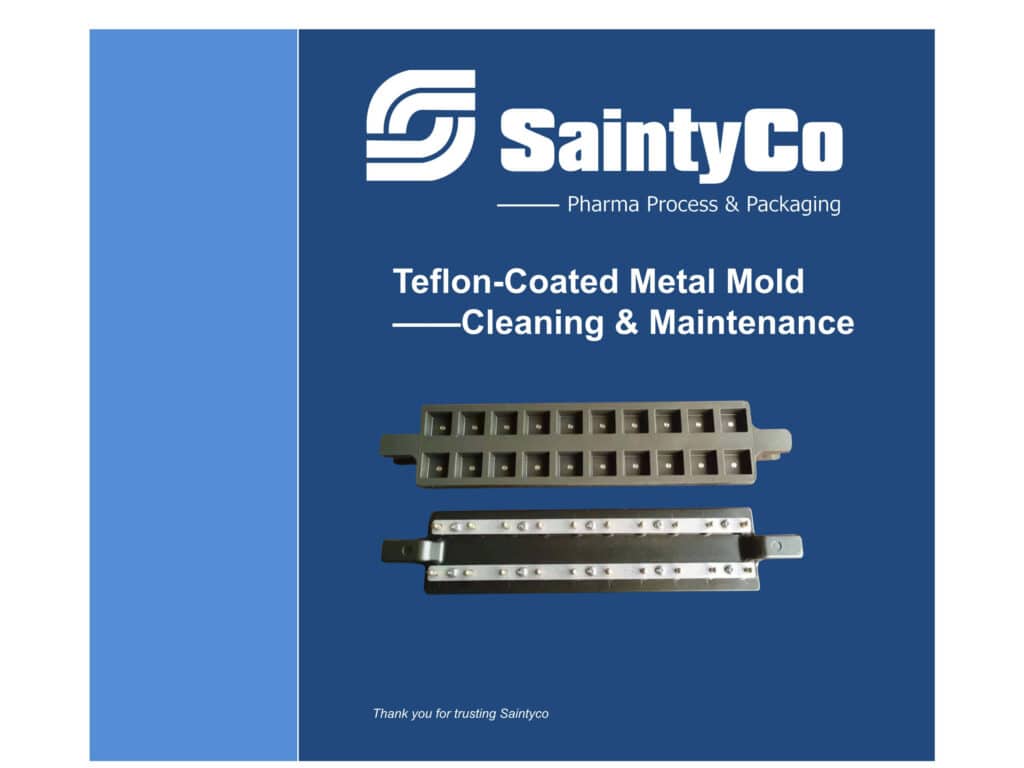

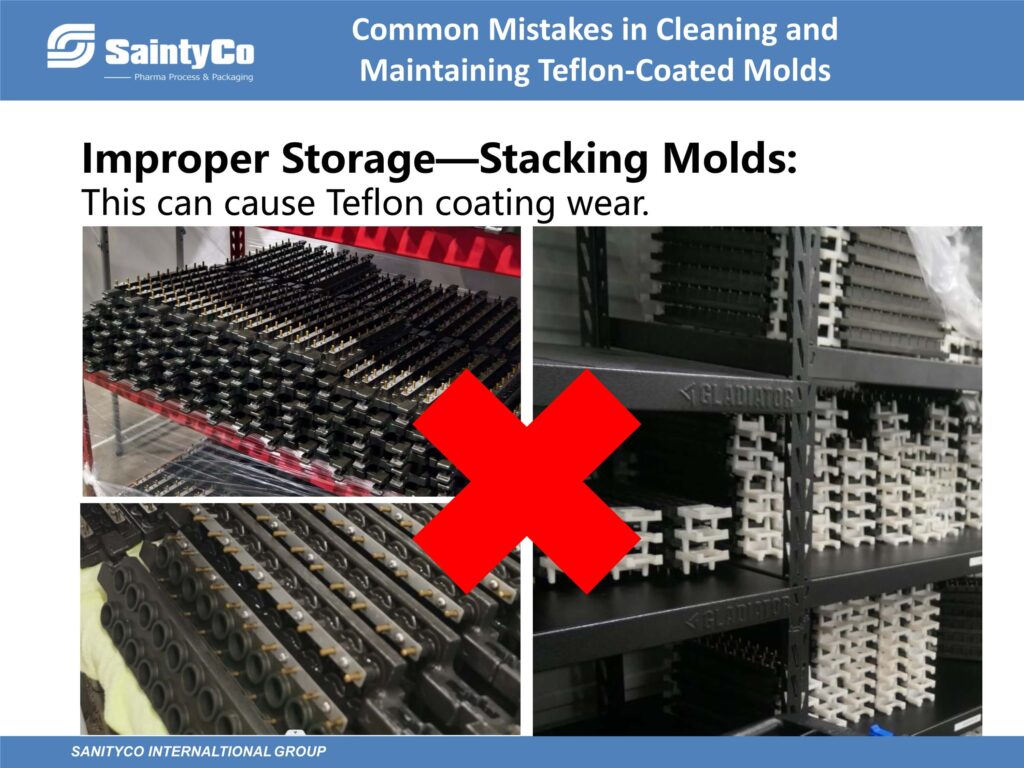

Cleaning and Maintenance of Gummy Molds

Proper cleaning and maintenance of gummy molds are essential for their longevity and the quality of your gummies. Here are some tips from SaintyCo:

- Use Appropriate Cleaners: Employ mild detergents specifically designed for Teflon surfaces to remove dirt effectively without damaging the mould.

- Gentle Cleaning: Use a soft brush and warm water for manual cleaning. Avoid abrasive tools. For stubborn stains, a non-metallic scraper can be used carefully.

- Machine Cleaning: Steamers or dishwashers can be used for deep cleaning to remove stubborn grease.

- Drying: Wipe with a clean, soft cloth or use an air gun to keep molds dry.

- Proper Storage: Store cleaned and dried molds in a dry, well-ventilated area, avoiding direct sunlight and humid environments. If space is limited, use protective materials between stacked molds to prevent friction.

.

Additional Resources

For more information on mold cleaning and maintenance, refer to the detailed PDF guide provided by SaintyCo. (Leave me an ER for a digital copy)

.

.

Features of SaintyCo Gummy Molds

SaintyCo gummy molds offer a range of innovative features designed to enhance your gummy production efficiency and product quality:

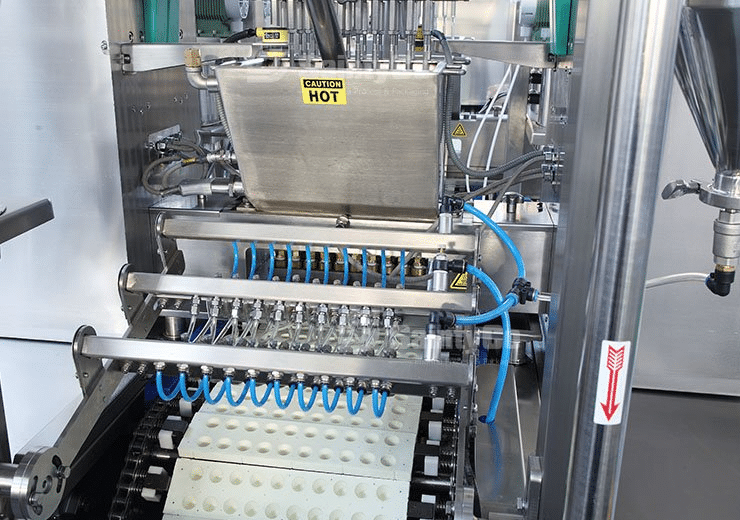

- Quick Release Tooling: SaintyCo molds are designed for easy and quick demolding, reducing production time and minimizing the risk of damaging gummies. The quick-release tooling of SaintyCo G-series gummy-making machines streamlines production and maximizes output. No more screwing molds onto the conveyor—with SaintyCo's quick mold release system, you can easily remove and replace molds without tools, reducing cross-contamination risks and saving valuable production time.

.

.

- High-Quality Materials: Made from durable materials like Teflon-coated aluminum and high-grade silicone, ensuring long-lasting performance and ease of cleaning.

- Custom Designs: Ability to create custom gummy molds tailored to your specific needs, allowing for unique shapes and branding.

- Heat Resistance: Withstands high temperatures during the production process, maintaining shape and quality.

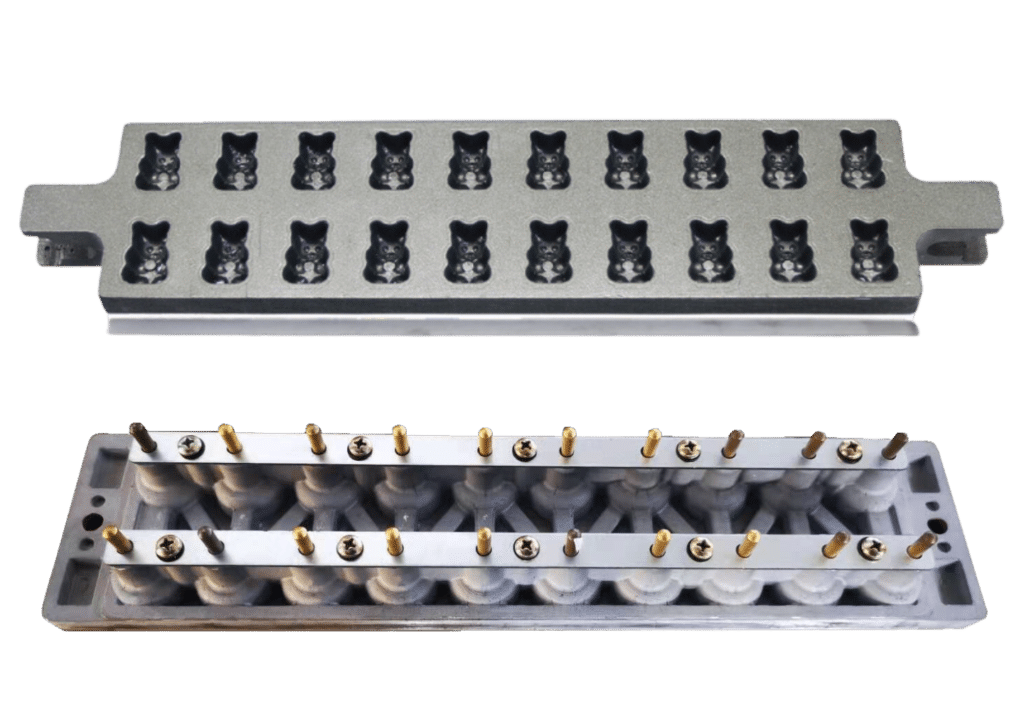

- Food-Grade Stainless Steel Ejector Pins: SaintyCo has a game-changing solution for mold issues in gummy production: food-grade stainless steel ejector pins. They eliminate toxic contamination caused by rusting brass pins. These SS 304 ejector pins are durable, non-reactive to food components, and comply with food safety standards. Our custom Teflon-coated aluminum gummy molds with SS 304 ejector pins have resolved mold issues for several clients.

.

.

Large Gummy Molds

For businesses aiming to produce larger gummies, SaintyCo offers molds that uphold the highest standards of quality and efficiency. These molds are ideal for creating bulkier gummy products without sacrificing detail or quality. They integrate seamlessly with SaintyCo's production lines, ensuring consistent and reliable performance.

.

Customizing Your Gummy Molds

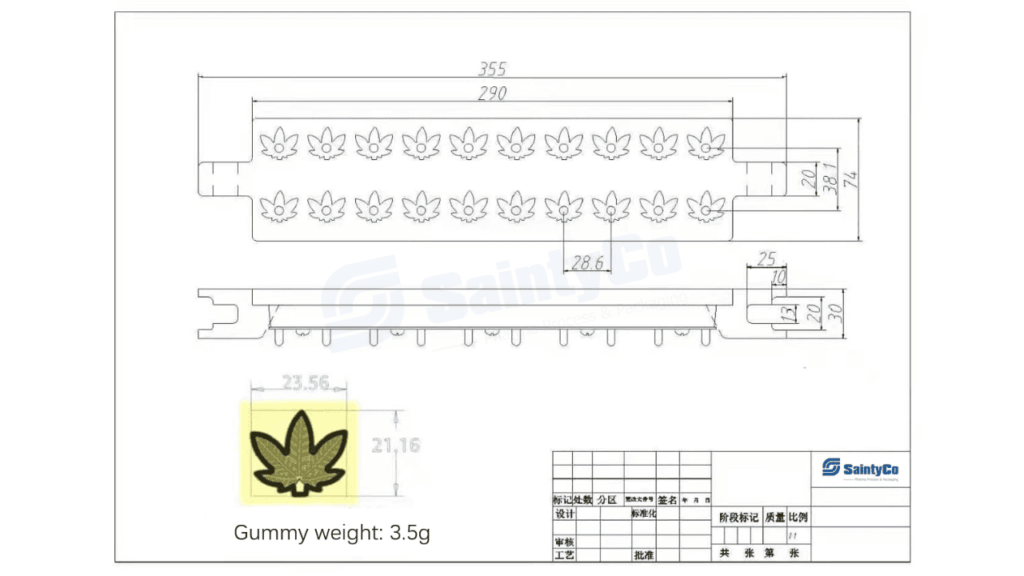

When partnering with SaintyCo, we take several factors into account to ensure the molds meet your specific needs:

- Gummy Shape: The shape is crucial. We offer popular shapes like squares and gum drops, which are well-received in the market. Custom shapes can also be created based on your requirements.

- Size and Weight: We design molds to produce gummies ranging from 2.5g to 4g, ensuring consistency in dosing and portion control, especially important for supplements and cannabis-infused gummies.

- Mold Layout: We provide layout recommendations for optimal mold usage, helping to maximize production efficiency.

- Prototyping: If you have specific requirements, we can create a small sample mold (free of charge) and send it to you for approval before proceeding with the full order. This ensures the final product meets your expectations.

.

.

Order Process for SaintyCo Gummy Molds

Ordering SaintyCo gummy molds is straightforward and efficient. Here’s how the process works:

- Choose or Customize: Select from our standard molds or send us a drawing/sample of your desired gummy shape, including weight and dimensions.

- Dimensional Drawing: We will generate a dimensional drawing of your product mold and send it to you for approval.

- Place Order: Once the drawing is approved, proceed with placing your order by making the down payment.

- Fabrication: We will start the fabrication process, which typically takes 3-4 weeks.

- Delivery: After production, we arrange for shipping and delivery to your specified location.

For additional tooling or support, contact us directly at GummyGenix by SaintyCo.

.

Summary

Choosing the right gummy mold is crucial for your business's success. Evaluate the pros and cons of different materials and ensure proper maintenance to keep your production line running smoothly. SaintyCo's gummy molds are particularly beneficial for those utilizing our production lines, ensuring optimal performance and high product quality. Additionally, 95% of SaintyCo's clients choose metal molds for their semi- or fully automated gummy manufacturing equipment due to their durability and efficiency. For more detailed guidance, reach out to GummyGenix by SaintyCo for expert advice and quality products.

By following these guidelines and choosing the right gummy molds, you can enhance your production efficiency and product quality, ensuring a successful gummy manufacturing operation.