In a world increasingly conscious of sugar intake, sugar-free gummies have emerged as a popular alternative. Yet, crafting them is no simple task.

Manufacturing sugar-free gummies involves challenges like texture preservation, flavor balance, and regulatory compliance. Solutions include selecting appropriate sweeteners like Stevia or Maltitol, and using tailored gummy machinery to ensure quality at various production scales.

While the initial challenges can seem daunting, understanding the right ingredients and gummy manufacturing equipment can turn these obstacles into opportunities. Read on to discover how you can efficiently produce high-quality sugar-free gummies, whether you're a small start-up or a large-scale manufacturer.

Sugar-free gummies are easier to produce than regular gummies.False

Sugar-free gummies face challenges like texture and flavor balance.

Stevia is a suitable sweetener for sugar-free gummies.True

Stevia is commonly used for its sweetness and low-calorie content.

How Do Sugar-Free Sweeteners Affect Gummy Texture and Flavor?

Sugar-free sweeteners revolutionize gummy candies, but their impact on texture and flavor is complex. Discover how these alternatives can transform your favorite treats without compromising taste or consistency.

Sugar-free sweeteners alter gummy texture and flavor by changing their structure and taste profile. They often require additional ingredients to mimic the mouthfeel and sweetness of sugar, which can introduce new textures and flavors.

Impact on Texture

When sugar is removed from gummies, its role as a bulking agent is lost. This often leads to changes in texture, as sugar contributes to both the chewiness and stability of gummies. For example, Maltitol1 can replicate the mouthfeel of sugar, offering a similar texture, but it may cause digestive discomfort if consumed in large amounts.

Sweeteners like Erythritol2 often bring a cooling sensation, which can alter the perceived texture when chewed. To counterbalance this, manufacturers sometimes blend erythritol with other ingredients like tapioca syrup to maintain a desirable chew.

| Sweetener | Best Use | Texture Impact |

|---|---|---|

| Maltitol | Stability | Similar to sugar but may cause digestive issues. |

| Erythritol | Low-sugar claims | Cooling effect that can alter chewiness. |

Influence on Flavor

The flavor of gummies is another aspect heavily influenced by sugar-free sweeteners. Stevia3, for instance, provides intense sweetness but can leave a bitter aftertaste. To mitigate this, it is often paired with bulking agents that help in masking unwanted flavors.

Monk fruit sweetener offers pleasant sweetness without a bitter aftertaste, though its use may be limited due to regulatory issues4 in certain regions.

| Sweetener | Best Use | Flavor Impact |

|---|---|---|

| Stevia | Natural sweetener | High sweetness with potential bitterness. |

| Monk Fruit | Natural options pending approval | Pleasant taste, no aftertaste issues. |

Balancing Act

Achieving the perfect balance of texture and flavor in sugar-free gummies is a delicate task that involves more than just replacing sugar with a substitute. It requires careful formulation to avoid undesirable flavors and maintain structural integrity. For instance, Isomalto-Oligosaccharide Syrup5 not only adds sweetness but also acts as a fiber source, offering health benefits while maintaining texture.

The combination of different sweeteners and additives can help manufacturers create sugar-free gummies that meet consumer expectations while adhering to health trends. However, the choice of sweetener impacts everything from production efficiency to the overall consumer experience.

Maltitol can cause digestive issues in large amounts.True

Maltitol mimics sugar's texture but may cause digestive discomfort if overconsumed.

Monk fruit sweetener always has a bitter aftertaste.False

Monk fruit provides sweetness without the bitter aftertaste common with stevia.

What Equipment Is Essential for Small-Scale Sugar-Free Gummy Production?

Considering venturing into sugar-free gummy production? Discover the essential equipment to start a small-scale operation efficiently. From compact depositors to customizable molds, learn how to craft delightful, health-conscious treats.

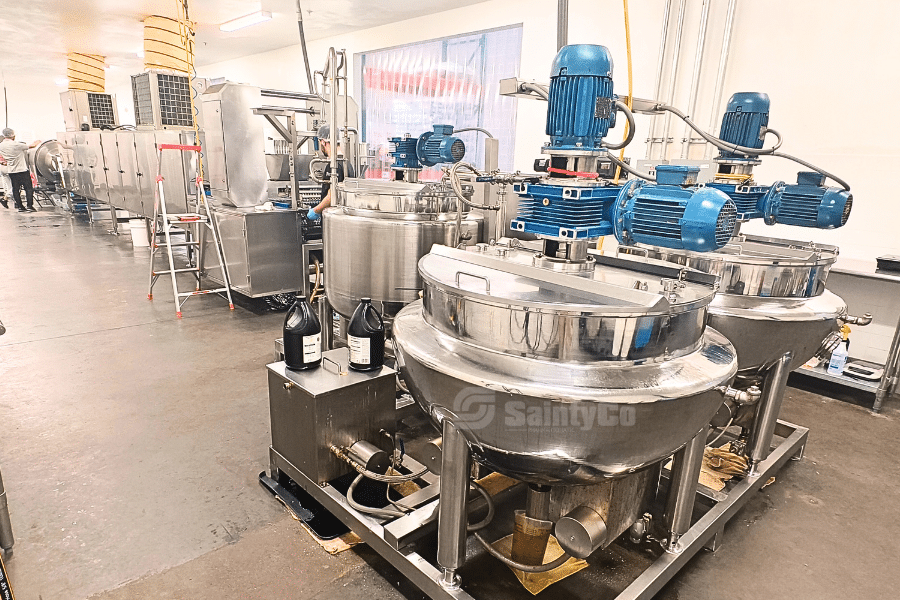

Essential equipment for small-scale sugar-free gummy production includes cooking & mixing tanks, batch depositors with precise dosing systems, and customizable molds. These tools ensure quality and consistency in crafting sugar-free gummies.

Essential Equipment for Your Start-Up

To kick off small-scale sugar-free gummy production, you'll need a few key machines that ensure efficiency and quality:

- Mixing Tanks: A reliable tank is crucial for blending ingredients thoroughly. Ensure it accommodates both pectin and gelatin bases.

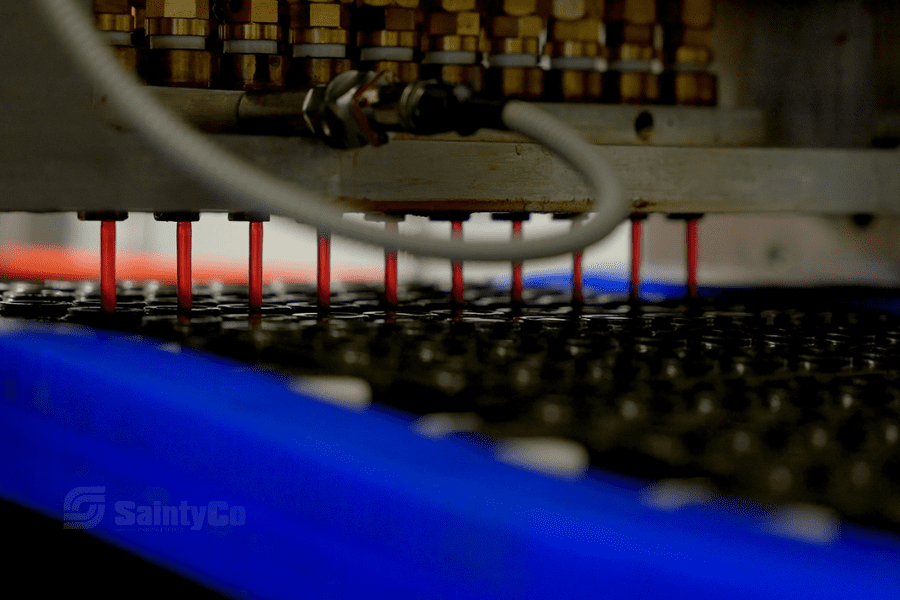

- Batch Depositors: Machines like the DM-20S Small Batch Depositor are indispensable. They handle 6,000–10,000 gummies/hour, perfect for experimenting with sweeteners like Stevia or Maltitol.

- Precision Dosing Systems: These systems are vital for managing sugar substitutes with varied consistencies.

| Equipment | Features | Output |

|---|---|---|

| 100L Mixing Tanks | Accommodates pectin and gelatin-based gummies, handles varied consistencies of sugar substitutes | 40kgs/h |

| DM-20S Batch Depositor for Precision Dosing | Compact, easy to clean | 6,000–10,000 gummies/hour |

Customizable Molds

Invest in molds that allow you to experiment with different shapes and sizes. This flexibility can be crucial when adapting to consumer trends or branding needs. Customizable molds ensure each gummy is unique yet consistent.

Integrated Oil Coating Systems

This feature is not just a bonus but a necessity. An integrated oil coating system helps prevent stickiness and enhances shelf stability. This system works seamlessly with the rest of the equipment to ensure each batch is consistent.

Why Opt for Small-Scale Machinery?

Choosing compact machinery like the DM-20S Small Batch Depositor6 offers several benefits. It allows you to test various sweetener blends efficiently and make quick adjustments based on recipe refinement needs.

Utilize these tools to lay a solid foundation for your gummy production journey. With the right equipment, achieving consistency and quality in sugar-free gummies becomes feasible and straightforward. Explore more about enhancing your production capabilities by incorporating precision dosing systems7.

Batch depositors produce 6,000–10,000 gummies per hour.True

The DM-20S Batch Depositor is designed to handle this output range.

Mixing tanks are unnecessary for sugar-free gummy production.False

Mixing tanks are crucial for blending ingredients like pectin and gelatin.

How Can Medium-Scale Producers Optimize Efficiency in Gummy Manufacturing?

Medium-scale gummy manufacturers face unique challenges in optimizing efficiency. By leveraging tailored machinery, refining ingredient selection, and streamlining production processes, they can enhance productivity without sacrificing quality. Let's explore effective strategies for optimizing gummy production efficiency.

Medium-scale gummy manufacturers can optimize efficiency by choosing the right gummy making machines, selecting appropriate sweeteners, and refining production processes. Using dual-color production lines and automated systems boosts output while maintaining product quality.

Choosing the Right Equipment for Medium-Scale Production

The choice of equipment significantly impacts production efficiency. For medium-scale operations, machines like the G40 and G80 Gummy Production Lines offer ideal solutions.

| Machine Model | Output | Key Features |

|---|---|---|

| G40 | 15,000/hour | Dual-color capability, precise depositing |

| G80 | 30,000/hour | Advanced cooling, oil-spraying systems for consistency |

Selecting these lines allows manufacturers to scale operations efficiently. The SaintyCo G80's advanced cooling system8 ensures that sugar-free formulations retain their stability and texture. This helps meet consumer demands for high-quality products.

Optimizing Ingredient Selection

Choosing the right sweeteners is crucial. Options like Maltitol and Erythritol balance taste and texture in sugar-free gummies.

- Maltitol mimics sugar well, stabilizing the gummy matrix. However, it requires careful dosing to prevent digestive discomfort.

- Erythritol, often used with tapioca syrup, prevents recrystallization and is suitable for low-sugar claims.

By refining these selections, manufacturers can maintain a consistent flavor profile that appeals to health-conscious consumers.

Streamlining Production Processes

Efficiency in gummy manufacturing isn't just about machinery; it's also about processes.

- Automation: Implementing PLC systems allows for seamless operation and recipe adjustments, enhancing consistency.

- Customizable Molds: Using custom molds9 allows producers to tailor gummy shapes to consumer trends and branding, providing an edge in a competitive market.

Streamlining these elements reduces downtime and waste, ensuring optimal resource use during production cycles.

By focusing on these areas, medium-scale producers can improve operational efficiency while maintaining high standards of product quality. These strategies not only streamline production but also position businesses competitively within the ever-growing gummy market.

The G40 line produces 30,000 gummies per hour.False

The G40 line produces 15,000 gummies per hour, not 30,000.

Maltitol can cause digestive discomfort if overdosed.True

Excessive Maltitol intake may lead to digestive issues.

What Are the Key Considerations for Large-Scale Production of Sugar-Free Gummies?

Scaling sugar-free gummy production demands a strategic approach to ingredients, machinery, and market trends. Successfully balancing these elements ensures a delicious, compliant product that meets consumer demands.

Key considerations for large-scale production of sugar-free gummies include selecting appropriate sweeteners, optimizing gummy production lines for efficiency, ensuring regulatory compliance, and maintaining product quality and consistency.

Choosing the Right Sweeteners

The choice of sweetener directly impacts the taste, texture, and overall success of sugar-free gummies. Maltitol is often chosen for its ability to mimic sugar's sweetness and texture while maintaining stability in the gummy matrix. However, it may cause digestive discomfort at high doses. Erythritol, paired with tapioca syrup, is effective for low-sugar claims but may introduce a cooling aftertaste. Explore various sweeteners10 to understand their benefits and limitations.

Machinery Optimization for Efficiency

To achieve high production outputs without compromising quality, manufacturers need advanced machinery. The G150 Gummy Production Line, capable of producing up to 60,000 gummies per hour, is equipped with precision dosing and temperature control—crucial for maintaining sugar-free recipes. Equipment like this ensures consistent product quality while minimizing waste. For more insights on equipment efficiency, check sugar-free gummy machines11.

Regulatory Compliance

Navigating the regulatory landscape is essential for any large-scale production. Sweeteners like Monk Fruit are still awaiting approval in some regions such as the EU. Understanding these restrictions helps avoid costly setbacks. Additionally, claims like vegan or gluten-free must align with both ingredient choices and local regulations. Learn more about regulatory challenges12 in sugar-free gummy production.

Ensuring Product Quality and Consistency

Maintaining the desired texture and taste across large batches requires precise control over formulation and manufacturing processes. This involves selecting the right combination of sweeteners and bulking agents to mimic traditional sugar's role in providing structure. A well-calibrated production line can ensure each gummy maintains its intended mouthfeel and flavor profile. Investigate more about maintaining consistency13 in large-scale gummy production.

Maltitol causes digestive discomfort in large amounts.True

Maltitol can cause digestive issues when consumed in high doses.

Monk Fruit is approved for use in all regions.False

Monk Fruit is not yet approved in some regions, like the EU.

How Do Regulatory Requirements Impact Sugar-Free Gummy Production?

Navigating regulatory requirements is crucial for producing sugar-free gummies. These rules impact ingredient choices, labeling, and manufacturing processes. Understanding these regulations can help manufacturers maintain compliance and market their products effectively.

Regulatory requirements significantly affect sugar-free gummy production by dictating permissible ingredients, labeling standards, and production practices. Compliance ensures product safety, quality, and marketability, aligning with consumer expectations and legal obligations.

Understanding Regulatory Guidelines

In the production of sugar-free gummies, regulatory guidelines play a pivotal role in shaping how products are developed and marketed. Different regions impose specific rules that manufacturers must follow to ensure their products are safe and compliant. In the United States, the FDA's regulations14 govern food safety standards, including those for sugar substitutes used in confectionery.

Permissible Ingredients

The choice of sweeteners and other ingredients is largely dictated by what is permissible under regulatory frameworks. For example, while some sweeteners like Stevia are widely accepted, others, such as Monk Fruit, may face restrictions in certain markets like the EU. The acceptance of these ingredients often depends on their classification as novel foods or their approval status in different jurisdictions.

Labeling Standards

Labeling requirements are another critical aspect of regulatory compliance. Manufacturers must accurately represent nutritional information and potential allergens on their packaging. Claims such as "sugar-free" or "low-calorie" need to be substantiated by the product's formulation and verified through appropriate testing. This ensures transparency and trust with consumers.

| Sweetener | Status in US | Status in EU |

|---|---|---|

| Stevia | Approved | Approved |

| Monk Fruit | Approved | Under Review |

| Allulose | GRAS | Restricted |

Production Practices

Regulatory bodies also influence the actual production practices by setting standards for hygienic processing and quality control. These standards aim to prevent contamination and ensure consistent product quality. Implementing precision dosing systems15 and starch-free technology can help manufacturers adhere to these regulations effectively.

Navigating International Markets

For manufacturers looking to expand internationally, understanding regional differences in regulations is crucial. While a product might meet all compliance requirements in one country, it may require reformulation or relabeling to enter another market successfully.

Regional trade agreements can also affect compliance strategies, necessitating a flexible approach to production and marketing.

By understanding these regulatory impacts, manufacturers can better navigate the complexities of producing sugar-free gummies that meet both consumer demands and legal standards globally.

Incorporating compliance into every stage of production—from ingredient selection to final packaging—ensures that sugar-free gummies not only delight customers but also uphold safety and quality standards effectively. Learn more about global compliance16 with strategic insights into international regulations.

Stevia is approved in both the US and EU for gummies.True

Stevia is listed as approved in both the US and EU according to the table.

Allulose is unrestricted in the European Union.False

The table indicates that Allulose is restricted in the EU.

Conclusion

Manufacturing sugar-free gummies presents challenges in texture, flavor, and compliance. Solutions include selecting suitable sweeteners and machinery tailored for various production scales to ensure quality and efficiency.

At GummyGenix by SaintyCo, we're here to support your journey with cutting-edge, GMP-compliant gummy manufacturing equipment designed for efficiency, precision, and adaptability. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality gummy products to life—together.

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Learn about Maltitol's role in replicating sugar's texture and its digestive impact. ↩

-

Discover why erythritol causes a cooling sensation and how it affects gummy texture. ↩

-

Explore methods to counteract the bitter aftertaste of Stevia in gummies. ↩

-

Understand the regulatory challenges of using monk fruit as a sweetener in different regions. ↩

-

Find out how Isomalto-Oligosaccharide syrup contributes to both taste and health benefits. ↩

-

Discover how this depositor can refine your gummy recipes efficiently. ↩

-

Understand how dosing systems improve consistency in sugar-free gummy production. ↩

-

Learn about SaintyCo G80's cooling systems, crucial for maintaining gummy stability, especially in sugar-free products. ↩

-

Discover how customizable molds can enhance branding and meet consumer preferences effectively. ↩

-

Understand the variety of sweeteners available and their effects on texture and taste. ↩

-

Discover machinery that enhances production efficiency while maintaining product quality. ↩

-

Navigate regulatory hurdles effectively to ensure compliance in different markets. ↩

-

Learn techniques to ensure product quality across large batches. ↩

-

Discover detailed FDA guidelines on sugar substitutes to ensure your gummy production aligns with safety standards. ↩

-

Explore how precision dosing systems enhance compliance with quality standards in gummy manufacturing. ↩

-

Gain insights into navigating global food regulations for successful international gummy market entry. ↩