Choosing between jelly and gummy candies can significantly impact your confectionery business's success. But how do you decide which is best for your market?

Jelly candies are soft and often preferred by health-conscious consumers due to vegan and sugar-free options, while gummy candies are chewier and appeal to a broader audience with fun shapes. Each offers unique benefits, depending on your target market's preferences and needs.

While both jelly and gummy candies have their distinct advantages, understanding their differences in texture, market appeal, and production methods is crucial for making an informed decision. Dive deeper into this article to explore these aspects and discover which candy type best suits your business goals.

Jelly candies are always sugar-free.False

Not all jelly candies are sugar-free; some contain regular sugar.

Gummy candies appeal to a broader audience.True

Gummy candies often have fun shapes and textures, attracting more people.

What Are the Key Differences in Texture Between Jelly and Gummy Candies?

Have you ever wondered why jelly and gummy candies feel different in your mouth? Their textures vary due to distinct ingredients and manufacturing processes. Let's explore these sweet differences.

Jelly candies are softer and more delicate, using pectin for a smooth texture, while gummy candies are firmer and chewier, thanks to gelatin. These ingredients define their unique mouthfeel.

The Ingredients Behind the Texture

When it comes to jelly candies, pectin is the star player. This plant-based gelling agent creates that soft and delicate texture1 you experience. As pectin interacts with sugar and acid, it forms a gel-like consistency, making jelly candies melt smoothly in your mouth.

In contrast, gummy candies rely on gelatin, derived from animal collagen. This ingredient imparts a firm and chewy texture2 that defines gummies. Gelatin's elasticity allows for those satisfying bites into bear-shaped or worm-like treats.

Manufacturing Processes for Jelly and Gummy Candies

Jelly candies are typically made through a process called "batch cooking", where ingredients such as sugar, water, and pectin are combined in a kettle and heated until a clear, smooth mixture forms. The mixture is then deposited into molds, cooled, and demolded into various shapes. The result is a soft, delicate candy with a smooth texture and gentle bite.

Gummy candies, on the other hand, follow a different path. The gelatin-based mixture is deposited through starch or starchless molding, depending on the production line. In starch molding, the mixture is poured into cornstarch-coated trays to set, while starchless molding uses metal or silicone molds for a cleaner process. Gummy candies require additional drying and curing time to achieve their signature firmness and chewiness.

| Candy Type | Main Ingredient | Texture | Production Method |

|---|---|---|---|

| Jelly | Pectin | Soft and delicate | Batch cooking |

| Gummy | Gelatin | Firm and chewy | Starch/starchless molding |

Market Preferences and Applications

Jelly candies appeal to those seeking a softer texture, often marketed as healthier alternatives3 because they can be made vegan or sugar-free. They're popular in fruit-flavored varieties or as vitamin-enriched snacks.

Gummies, with their fun shapes and chewy bite, attract a broad audience, including both children and adults. They're frequently used for functional products like CBD or nutritional supplements, capitalizing on their firm texture to deliver consistent doses4.

Understanding these differences can enhance your appreciation of these treats next time you reach for a sweet snack!

Explore the unique confectionery machinery5 options that allow producers to create both types efficiently and hygienically. Whether you're intrigued by jelly's softness or gummy's chewiness, there's a fascinating world of candy texture waiting to be discovered.

Jelly candies use gelatin for their texture.False

Jelly candies use pectin, not gelatin, for a soft texture.

Gummy candies require additional drying time.True

Gummy candies need drying to achieve their firm texture.

How Do Jelly Candy and Gummy Bears Cater to Different Consumer Markets?

Jelly and gummy candies have captivated diverse audiences with their distinct textures and flavors. But what makes them appeal to different consumer markets, and how do manufacturers cater to these preferences?

Jelly and gummy candies target varied markets through texture, ingredients, and form. Jelly candies attract health-conscious consumers with vegan options, while gummy candies' chewy texture appeals to children and adults alike. Both types can be enriched with nutrients or CBD.

Texture Matters: The Soft vs. Chewy Debate

Texture plays a crucial role in distinguishing jelly from gummy candies. Jelly candies, known for their softness6, often use pectin, making them ideal for those who prefer a delicate bite. Health-conscious individuals lean towards jellies, particularly because of the vegan7 possibilities without gelatin.

In contrast, gummy candies are celebrated for their chewiness8, thanks to the elasticity provided by gelatin. This satisfying texture attracts both children and adults, making gummies popular in fun shapes like bears and worms.

Ingredient Adaptability: Catering to Health Trends

Both jelly and gummy candies have embraced the shift towards healthier eating habits by offering low-sugar or sugar-free versions. Jelly candies are perfect for creating fruit-flavored or vitamin-enriched jellies9, appealing to the wellness market.

Gummy candies also enter this arena with fortified products such as CBD-infused10 gummies or nutritional supplements. Their ability to carry active ingredients without altering taste makes them a versatile choice for functional food markets.

| Candy Type | Key Ingredient | Popular Market |

|---|---|---|

| Jelly | Pectin | Health-conscious consumers |

| Gummy | Gelatin | Children, adults, functional foods |

Market Strategies: Design and Innovation

Manufacturers like SaintyCo utilize advanced machinery that allows for customizable molds11 and scalable production, enabling brands to experiment with unique designs that stand out in the market. This adaptability is essential in meeting varying consumer demands without sacrificing efficiency.

The ability to produce both jellies and gummies on a single production line, with options ranging from single-color gummies to dual-layer or filled jellies, showcases the flexibility required to cater to different markets. Such innovations ensure that companies can remain competitive while catering to diverse consumer preferences.

By leveraging these strategies, brands can successfully tap into niche markets while maintaining broad appeal across different demographic groups. Understanding these dynamics is essential for businesses aiming to thrive in the competitive confectionery landscape.

Jelly candies use pectin for a soft texture.True

Pectin is used in jelly candies to create a soft, delicate bite.

Gummy candies cannot be vegan.False

Gummies can be made vegan by using agar or pectin instead of gelatin.

What Are the Production Advantages of Jelly vs. Gummy Candies?

Jelly and gummy candies have distinct production advantages, appealing to different market niches. From texture to ingredient flexibility, these confections offer unique benefits that cater to diverse consumer preferences.

Jelly candies, softer and pectin-based, allow for vegan-friendly and sugar-free options. Gummy candies, gelatin-based, offer a chewier texture and are ideal for fun shapes and fortified products.

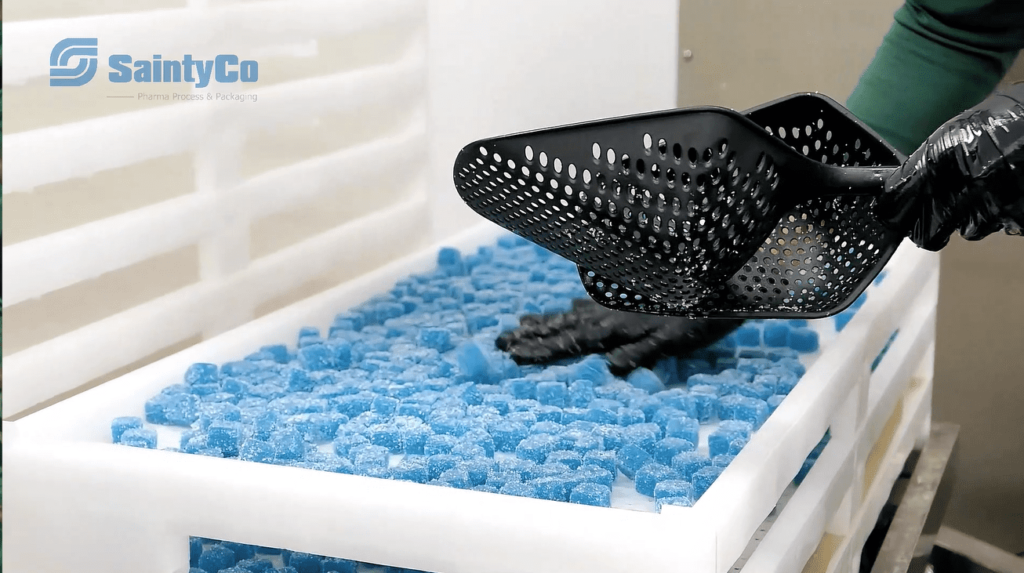

Watch this video to see the SaintyCo G150 Gummy Production Line in action! Designed for versatility, it effortlessly produces both pectin and gelatin-based gummies, as well as jelly candies in various shapes and sizes.

Texture and Ingredient Flexibility

Jelly candies are known for their softer texture12, often achieved through the use of pectin. This makes them suitable for creating melt-in-the-mouth experiences. The use of pectin also allows for the production of vegan-friendly and sugar-free varieties, aligning with health-conscious trends.

In contrast, gummy candies are characterized by their chewy, elastic texture, which is typically derived from gelatin. This makes gummies appealing to both children and adults who enjoy the satisfying bite of gummy bears or worms.

Market Appeal and Product Variety

Jellies are often preferred for fruit-flavored candies and functional products like vitamin-enriched or CBD-infused jellies. This is due to their ability to incorporate13 diverse flavors and functional ingredients seamlessly.

Gummies, on the other hand, are ideal for creating fun shapes and can be easily fortified with supplements. They cater to a broad audience and are commonly used in the production of nutritional supplements like CBD gummies.

| Feature | Jelly Candies | Gummy Candies |

|---|---|---|

| Main Ingredient | Pectin | Gelatin |

| Texture | Soft, delicate | Chewy, elastic |

| Popular Products | Fruit-flavored jellies, CBD jellies | Gummy bears, CBD gummies |

| Dietary Options | Vegan, sugar-free | Wide variety of shapes |

Production Efficiency and Equipment

Jelly production benefits from starch-free technologies, using hygienic rubber, plastic, or metal molds. This ensures consistent quality and a cleaner production environment. Additionally, jelly candy production lines can easily adapt molds and settings to create diverse products.

For gummy candies, production machinery is designed to efficiently produce high volumes of fun-shaped candies, often using automated processes to reduce labor costs. These machines allow for the rapid scaling of production while maintaining high standards of quality.

The versatility of machinery like SaintyCo's gummy manufacturing equipment allows manufacturers to produce both jellies and gummies efficiently without compromising quality. This flexibility is crucial for businesses looking to diversify their healthy gummy product range14 and meet various consumer demands.

Jelly candies are always vegan-friendly.False

Not all jelly candies are vegan; some may contain non-vegan ingredients.

Gummy candies use gelatin for a chewy texture.True

Gelatin is the primary ingredient in gummies, providing their chewiness.

How Can SaintyCo Machinery Benefit Your Candy Production?

Unlock the potential of your candy production with SaintyCo machinery, designed to enhance efficiency, flexibility, and quality in your operations. Discover how these machines can revolutionize your candy-making process.

SaintyCo jelly/gummy making machinery benefits candy production by offering versatile, efficient, and hygienic solutions. From flexible molds to high-capacity lines, these machines ensure consistent quality and scalable output for various candy types.

Versatile Production Capabilities

SaintyCo machinery stands out for its ability to produce diverse candy types, from jellies and gummies15 to hard candies and toffees. This versatility allows you to cater to a wide range of consumer preferences without needing multiple production lines.

| Candy Type | Key Features of Machinery |

|---|---|

| Jellies | Soft texture, customizable flavors |

| Gummies | Chewy consistency, vibrant colors |

| Hard Candies | Durable, long shelf life |

Enhanced Efficiency and Productivity

One of the standout features of SaintyCo's machinery is its ability to enhance production efficiency. Automated processes reduce manual labor needs, cutting down on operational costs. With some machines capable of producing up to 240,000 pieces per hour, you can significantly boost your output.

For those looking to expand their market reach, SaintyCo offers scalable solutions that can transition from small-scale R&D units to full-scale production lines.

Hygienic and Compliant Operations

Hygiene is paramount in candy production, especially for products that are vitamin-enriched or contain CBD. SaintyCo machinery supports starch-free production, utilizing rubber, plastic, or metal molds that maintain a cleaner environment and meet stringent hygiene standards.

This compliance with industry regulations ensures that your products are safe and consistent in quality, an essential factor in gaining consumer trust and regulatory approval.

Customization for Market Differentiation

Creating unique candy designs can set your brand apart. SaintyCo's machinery offers customizable molds16 that allow you to craft distinctive products tailored to your market's needs. Whether it's single-color gummies or dual-layer jellies, these machines provide the flexibility needed for innovation.

Such customization not only enhances aesthetic appeal but also opens doors for new product lines, potentially increasing your market share.

Cost-Effectiveness and Support

Investing in SaintyCo machinery means cost savings through reduced waste and increased speed. The automation reduces human error and ensures uniformity across batches.

Moreover, with comprehensive support including facility layout design and customized gummy formulations17, you can rest assured knowing that SaintyCo is committed to your success. This holistic support system aids in smooth transitions during scaling or launching new product lines.

SaintyCo machines can produce up to 240,000 candies per hour.True

SaintyCo machinery enhances production efficiency with high output rates.

SaintyCo machinery requires manual labor for candy production.False

Automation reduces manual labor, cutting operational costs and boosting efficiency.

Conclusion

This article compares jelly and gummy candies, highlighting their textures, ingredients, market appeal, and production methods to help confectionery businesses choose the best option for their target audience.

At GummyGenix by SaintyCo, we are here to support your journey with cutting-edge, GMP-compliant jelly candy/gummy bear manufacturing equipment designed for efficiency, precision, and adaptability. Jelly/gummy candy machines from GummyGenix by SaintyCo are manufactured to deliver on these priorities, offering efficient production, rapid changeovers, and support for diverse formulations. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality candy products to life—together.

Jelly Candy/Gummy Candy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Discover how pectin creates the smooth, melt-in-the-mouth texture of jelly candies. ↩

-

Learn how gelatin provides gummies with their distinctive chewy texture. ↩

-

Understand why jelly candies can be marketed as healthier alternatives. ↩

-

Find out how gummies are used for consistent dosing in supplements. ↩

-

Explore machinery options that enable efficient production of both candy types. ↩

-

Explore why soft textures in candy appeal to certain consumers, enhancing your understanding of market preferences. ↩

-

Learn about the health and ethical benefits of vegan jelly candies to understand their market appeal. ↩

-

Discover what gives gummy candies their distinctive chewiness and why it's a consumer favorite. ↩

-

Find out how vitamin-enriched jellies are crafted to appeal to health-conscious consumers. ↩

-

Uncover the benefits of CBD-infused gummies for health-focused markets. ↩

-

Understand how customizable molds can help brands differentiate their products. ↩

-

Understanding pectin's role in creating jelly's soft texture can help producers meet consumer preferences for vegan-friendly options. ↩

-

Explore how jellies can be enhanced with vitamins or CBD, offering insights into their market potential. ↩

-

Learn how adaptable machinery can help expand healthy gummy product lines efficiently and cost-effectively. ↩

-

Discover how SaintyCo machinery enables the production of various candy types, enhancing product diversity. ↩

-

Explore the customization capabilities of SaintyCo molds for unique candy designs. ↩

-

Learn about the support GummyGenix by SaintyCo provides for creating customized gummy formulations. ↩