Jelly Babies and gummy bears are beloved candies worldwide, but have you ever wondered what truly sets them apart?

Jelly Babies and gummy bears differ primarily in texture and ingredients. Jelly Babies are softer due to higher starch or pectin content, while gummy bears are chewier with gelatin as the main gelling agent. Their production processes also vary, with Jelly Babies often requiring aeration and gummy bears needing precise temperature control.

While both candies hold a cherished spot in confectionery culture, the unique characteristics of Jelly Babies and gummy bears make them suitable for different preferences and occasions. Dive deeper into the nuances of these treats to discover which aligns with your taste and production needs.

Jelly Babies are softer than gummy bears.True

Jelly Babies contain more starch or pectin, making them softer.

Gummy bears use pectin as their main gelling agent.False

Gummy bears primarily use gelatin, not pectin, for their texture.

How Does Texture Differ Between Jelly Babies and Gummy Bears?

Jelly Babies and Gummy Bears may seem similar, but their textures reveal distinct differences. This article explores how each candy achieves its unique mouthfeel, from ingredients to production techniques.

Jelly Babies and Gummy Bears differ in texture primarily due to their gelling agents. Jelly Babies use pectin or starch for a softer texture, while Gummy Bears rely on gelatin for a chewier consistency.

|

|

|---|

Jelly Babies vs Gummy Bears

Key Ingredients and Their Impact

Jelly Babies are crafted with pectin or starch, creating a softer, more delicate texture. These ingredients make them feel more like a marshmallow, often described as tender and squishy. In contrast, Gummy Bears utilize gelatin, which results in a firmer, chewier texture.

| Candy Type | Key Ingredient | Texture Description |

|---|---|---|

| Jelly Babies | Pectin/Starch | Soft, Squishy |

| Gummy Bears | Gelatin | Chewy, Firm |

Production Techniques

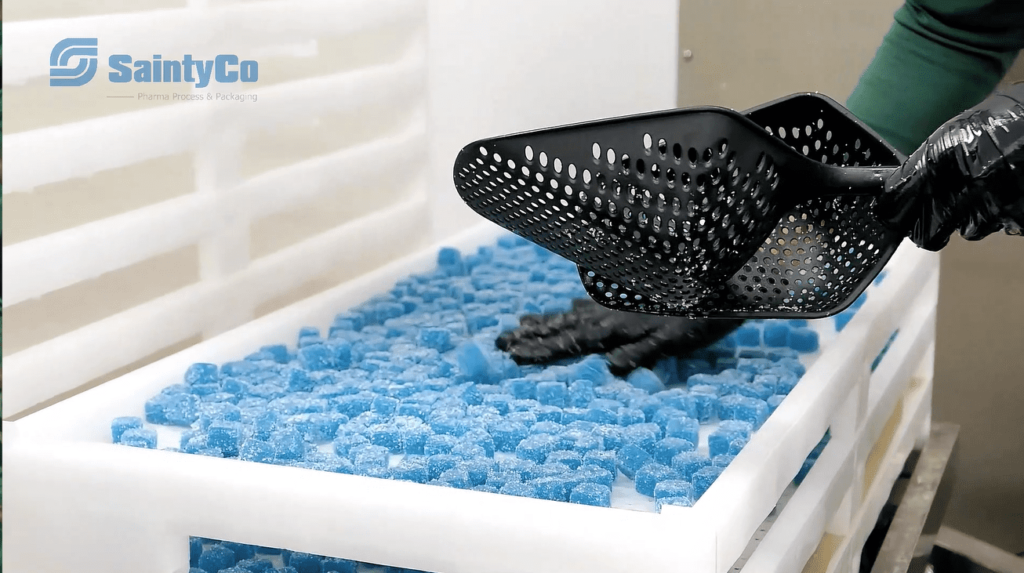

The production of these candies further enhances their textural differences. Jelly Babies often require aeration steps that incorporate air into the mixture, giving them a lighter feel. They are usually formed in rounded molds, which contributes to their soft finish. This process aligns well with equipment like the DM-50X Small Batch Depositor1 for small-scale operations.

Gummy Bears, on the other hand, undergo a more controlled temperature deposition process. The use of sharp, intricate molds is crucial to achieve their precise shapes and chewy texture. High-precision machinery such as the G80 Automated Gummy Production Line2 supports this detailed production.

Customization and Flexibility

Modern production lines offer versatility in creating both types of candies. Systems like the G40 Starchless Gummy Production Line3 allow manufacturers to switch between different candy types by adapting mold designs and ingredient settings. This flexibility is essential for meeting various consumer demands, including vegan or sugar-free options.

The ability to customize recipes with precise settings supports diverse formulations like dual-color or centrally filled candies. Such innovations cater to evolving market trends towards healthier and allergen-free products, as seen in the growing popularity of vegan gummies4.

For those interested in exploring the specific machinery that supports this flexibility, it’s worth examining solutions like the DM-50X Small Batch Depositor5, which provides efficiency even for niche projects.

Jelly Babies are firmer than Gummy Bears.False

Jelly Babies are softer due to pectin or starch, unlike firm Gummy Bears.

Gummy Bears use gelatin for a chewy texture.True

Gelatin is the key ingredient that gives Gummy Bears their chewy texture.

What Ingredients Make Jelly Babies Softer Than Gummy Bears?

Ever wondered why Jelly Babies melt in your mouth while gummy bears are a chewy delight? The secret lies in the ingredients and production processes.

Jelly Babies are softer due to higher starch or pectin content, while gummy bears use gelatin for a firmer texture. The choice of gelling agents primarily dictates their distinct textures.

Ingredients That Define Texture

Jelly Babies primarily use pectin6 or starch as gelling agents. These components create a softer, more tender feel. The lightness is often enhanced by aeration, giving Jelly Babies their signature melt-in-the-mouth texture.

In contrast, gummy bears are crafted with gelatin, which is known for its firm and elastic properties. This ingredient provides the chewy consistency that gummy bears are famous for. The detailed molding and controlled temperature during production further solidify their texture.

| Candy Type | Gelling Agent | Texture |

|---|---|---|

| Jelly Babies | Pectin/Starch | Soft |

| Gummy Bears | Gelatin | Chewy |

The choice between pectin7 or gelatin influences not only the texture but also the shelf life and resilience to environmental conditions. For instance, pectin-based candies can offer better resistance to high temperatures compared to gelatin-based ones.

Market Trends and Innovations

With increasing demand for vegan and allergen-free options, many producers are exploring alternatives to gelatin. Utilizing pectin allows manufacturers to tap into the growing market for vegan confectionery without compromising on texture or flavor.

For businesses looking to diversify their product line, machinery like the G40 Starchless Production Line8 provides flexibility to switch between different candy types, accommodating both traditional and modern consumer preferences.

-

Vegan and Sugar-Free Gummies: As health-conscious consumers grow in numbers, innovations in candy production aim at meeting these preferences with precision depositing and hygienic processes.

-

Customization Potential: Dual-hopper systems enable producers to create multi-layered or filled candies, adding variety to product offerings.

Considering these factors can guide confectionery producers in choosing the right ingredients and equipment for their specific market needs. With the right approach, it's possible to achieve the perfect balance between softness and chewiness that consumers love.

Whether you're a startup or an established brand, understanding these ingredient differences can help refine your product strategy and align it with current market demands.

Jelly Babies use gelatin as a gelling agent.False

Jelly Babies use pectin or starch, not gelatin, for a softer texture.

Gummy bears are firmer due to gelatin use.True

Gelatin provides the chewy and firm texture characteristic of gummy bears.

Why Do Candy Production Processes Vary: Jelly Babies vs Gummy Bears?

Candy production processes vary due to ingredients and desired textures. Jelly Babies and Gummy Bears use distinct gelling agents, affecting molds, aeration, and temperature control. Understanding these differences helps manufacturers choose suitable candy making equipment for optimal results.

The variation in gelling agents translates to different production techniques. Jelly Babies' softer texture comes from using rounded molds and aeration methods to achieve lightness. By contrast, gummy bears require precise temperature controls and sharper molds to maintain their iconic firmness.

Production Process Insights

The manufacturing process also contributes to the textural differences. Jelly Babies are often made using rounded molds and require specific aeration steps to achieve a lighter feel. On the other hand, gummy bears demand sharp, intricate molds and precise temperature control during depositing.

Equipment Adaptability

Manufacturers must consider candy making equipment that can adapt to these varying production needs. Versatile jelly/gummy making machinery9 is essential to switch between different molds and formulations efficiently. For instance, some machines quickly transition between producing Jelly Babies and Gummy Bears by adjusting settings to support different textures and shapes.

The ability to adapt molds and recipes ensures manufacturers can respond to changing market demands without significant downtime or additional costs. This flexibility is particularly vital as consumer preferences evolve towards healthier options, such as vegan or sugar-free gummies.

Market Trends and Technology

With a growing demand for healthier candies, starchless technology becomes increasingly relevant. This innovation allows for the production of vegan and sugar-free gummies through precise depositing and hygienic processes. As such, manufacturers investing in starchless technology10 can cater to a broader range of consumer preferences, including those seeking functional gummies fortified with vitamins or CBD.

Furthermore, advancements in candy production technology enable producers to maintain quality across various production scales—from small batches to mass production—while meeting stringent regulatory standards.

Jelly Babies use gelatin as a gelling agent.False

Jelly Babies use starch or pectin, not gelatin, for a softer texture.

Starchless technology is crucial for vegan gummy production.True

Starchless technology allows precise depositing needed for vegan gummies.

Which Candy Is Better for Specific Dietary Needs?

Choosing candy that suits specific dietary needs can be challenging. Whether your target customers' vegan, gluten-free, or managing diabetes, there are sweet treats tailored to their lifestyle. Let's explore candies that meet different dietary requirements.

Candies tailored to dietary needs include sugar-free, vegan, and gluten-free options. Sugar-free candies use sweeteners like xylitol. Vegan candies avoid gelatin. Gluten-free candies eliminate wheat-based ingredients, ensuring safe consumption for those with celiac disease.

Sugar-Free Candies

Sugar-free candies are often crafted for those managing diabetes or reducing sugar intake. These candies replace sugar with sweeteners like stevia, xylitol, or erythritol. They offer a sweet taste without spiking blood sugar levels.

| Sweetener | Benefits |

|---|---|

| Stevia | Zero calories, natural plant extract |

| Xylitol | Low glycemic index |

| Erythritol | Low calorie, doesn't affect insulin |

For individuals focusing on sugar reduction, sugar-free options11 provide an alternative that satisfies the craving for sweetness.

Vegan Candies

Vegan candies cater to those who avoid animal products. These candies exclude gelatin, a common gelling agent derived from animal collagen. Instead, pectin or agar-agar serves as substitutes.

These alternatives not only adhere to vegan standards but also offer different textures. Exploring vegan candy choices12 can be beneficial for those committed to a plant-based lifestyle.

Gluten-Free Candies

Gluten-free candies are crucial for individuals with gluten intolerance or celiac disease. These candies ensure there are no wheat-based ingredients that could cause adverse reactions.

Incorporating gluten-free selections13 into diets can help maintain digestive health and prevent symptoms associated with gluten consumption.

Each category provides an opportunity to enjoy sweets while adhering to specific dietary guidelines. Understanding these options allows consumers to make informed choices that align with their health needs.

Sugar-free candies spike blood sugar levels.False

Sugar-free candies use sweeteners that don't affect blood sugar.

Vegan candies use gelatin as a gelling agent.False

Vegan candies avoid gelatin, using pectin or agar-agar instead.

Conclusion

Jelly Babies and gummy bears differ in texture due to their ingredients; Jelly Babies are softer with pectin or starch, while gummy bears are chewier, using gelatin as a gelling agent.

At GummyGenix by SaintyCo, we are here to support your journey with cutting-edge, GMP-compliant jelly/gummy candy manufacturing equipment designed for efficiency, precision, and adaptability. Our machines are fully compatible with regulatory standards, and we offer reliable after-sales support to keep your operations running smoothly.

Contact GummyGenix by SaintyCo to explore how our machinery and expertise can enhance your production line. Let’s bring your vision of quality jelly/gummy products to life—together.

Gummy Production Machinery from GummyGenix by SaintyCo | Click to Know More

-

Explore how this equipment enhances Jelly Baby production with its soft texture capabilities. ↩

-

Learn about the precision offered by this line for making chewy Gummy Bears. ↩

-

Discover how this versatile line adapts to different candy types and formulations. ↩

-

Understand how production adapts to create vegan-friendly gummy options. ↩

-

Check out how this machine performs in producing small-scale candy batches efficiently. ↩

-

Learn how pectin shapes the soft texture of confections and its benefits over gelatin. ↩

-

Discover the advantages of using pectin over gelatin, including texture and dietary preferences. ↩

-

Explore how this production line enhances flexibility and efficiency in making diverse confectioneries. ↩

-

Explore machinery that adapts to different candy types, ensuring flexible production processes. ↩

-

Understand how starchless technology supports the creation of vegan and sugar-free gummies. ↩

-

Explore top sugar-free candy options suitable for diabetics, offering safe indulgence without raising blood sugar levels. ↩

-

Discover leading vegan candy brands that ensure cruelty-free indulgence without compromising on taste. ↩

-

Identify trusted gluten-free candy brands to enjoy treats without gluten-related health concerns. ↩