Ever felt the frustration of pulling out gummies that just didn’t have that perfect texture? I know that feeling all too well.

To prevent gummies from curing too quickly in a gummy depositor, maintain an optimal mixture temperature of 90-100°C during pouring, avoid rapid cooling post-depositing, adjust Brix levels by increasing sugar concentration or reducing water content, choose proper molding techniques, and control humidity in the curing environment.

While these tips provide a quick fix, the world of candy-making is rich with intricacies. Join me as we explore this detailed guide to mastering every aspect of gummy-making.

Maintaining 90-100°C prevents gummies from setting too quickly.True

Keeping the mixture within this temperature range ensures optimal viscosity, preventing premature setting.

How Can Adjusting Brix Levels Improve Gummy Texture?

Did you know that tweaking the sugar concentration can transform your gummy texture?

Adjusting Brix levels, or sugar concentration, in gummy recipes helps control setting time and texture. A higher Brix level results in a firmer texture by slowing the setting process. Aim for a Brix level around 80 for optimal gummy consistency.

Understanding Brix Levels and Their Impact

Brix is a measure of sugar content in an aqueous solution, expressed as the percentage of sugar by weight. In gummy production, controlling Brix levels is crucial because sugar concentration directly influences both the setting time and the final texture of the gummies. Higher Brix levels increase the viscosity of the gummy mixture, slowing down the setting process and resulting in a firmer texture.

Increasing Sugar Content for Optimal Texture

By increasing the sugar content in your gummy recipe, you can achieve a desirable consistency. This is because higher sugar levels reduce water activity, which slows down gelatinization, allowing for a controlled and gradual setting. For best results, aim for a Brix level around 80. This ensures that your gummies will have the ideal chewiness and firmness without setting too quickly.

Reducing Water Content

Another effective way to adjust Brix levels is by reducing water content. Using concentrated sweeteners or reducing liquid ingredients in your recipe will increase the relative sugar concentration. This method not only enhances the texture but also contributes to a longer shelf life by lowering moisture content, which helps prevent microbial growth.

| Adjustment Method | Effect on Texture | Recommended Action |

|---|---|---|

| Increase Sugar Content | Firmer texture, slower setting | Aim for Brix level around 80 |

| Reduce Water Content | Enhanced chewiness, longer shelf life | Use concentrated syrups or less liquid |

Utilizing Concentrated Sweeteners

Concentrated sweeteners like corn syrup solids or invert sugar are excellent alternatives to traditional sugars. They help in achieving higher Brix levels without adding extra bulk, making them ideal for maintaining desired texture and consistency. These sweeteners also aid in moisture retention, which can further improve the mouthfeel of the gummies.

Monitoring and Measuring Brix Levels

To consistently produce gummies with perfect texture, it's essential to accurately measure and monitor Brix levels. A refractometer is a handy tool for this purpose. It allows you to measure the sugar concentration of your gummy mixture precisely. Regularly checking these levels during production can help you make real-time adjustments to maintain consistency throughout batches.

By understanding and manipulating Brix levels, you can refine your gummy-making process, ensuring that each batch has the perfect texture and chewiness.

Higher Brix levels lead to firmer gummy texture.True

Higher sugar content slows setting, resulting in firmer gummies.

Reducing water content decreases gummy shelf life.False

Reducing water increases shelf life by lowering moisture and microbial growth.

Why is Acid Timing Crucial in the Gummy-Making Process?

Timing the addition of acid can make or break your gummy candy's texture and consistency.

Acid timing in gummy making is vital because adding it too early can accelerate gelling, leading to premature setting. To control the texture and curing time, acids like citric acid should be added towards the end of the process.

The Chemistry Behind Gummy Making

Understanding the role of acids in gummy making requires a basic grasp of food chemistry. Acids like citric acid are used to balance sweetness and enhance flavor, but they also play a critical role in the gelling process. When added to a mixture containing gelatin, pectin, or other gelling agents, these acids lower the pH, which can speed up or slow down the setting process.

The Impact of Timing on Gelling

Acids should be introduced at the right stage to manage the setting speed. Adding acids too early can result in faster gelling, causing the gummies to set prematurely and potentially leading to a tough texture. Conversely, delaying acid addition allows you to control when the gelling reaction begins, offering more flexibility in crafting the perfect gummy texture.

Experimenting with Different Acids

Not all acids affect the gelling process in the same way. Switching from traditional citric acid to alternatives like encapsulated acids or malic acid can offer different benefits. Encapsulated acids are designed to release their acidity more slowly, providing greater control over the curing time. Malic acid, on the other hand, offers a different flavor profile and a gentler reaction with gelling agents.

| Acid Type | Reaction Speed | Flavor Profile |

|---|---|---|

| Citric Acid | Fast | Sharp, citrusy |

| Encapsulated Acid | Slow | Neutral |

| Malic Acid | Moderate | Tart, apple-like |

The Art of Balancing Acidity and Sweetness

Beyond its role in texture, acid also impacts the overall flavor balance of gummies. Finding the right acidity level is essential to prevent overwhelming sweetness or excessive tartness. By carefully timing when you add acid, you can achieve a harmonious balance that enhances both texture and flavor.

Practical Tips for Acid Timing

- Late Addition: Add your chosen acid towards the end of the cooking process to better control gelling speed.

- Monitor pH Levels: Use pH strips or a digital pH meter to ensure that your mixture maintains an optimal pH level.

- Consider Alternatives: Experiment with different acids or combinations to find what best suits your desired gummy texture and flavor profile.

Understanding and mastering acid timing is key to producing consistently high-quality gummies. By adjusting when and how you introduce acid into your gummy recipe, you can elevate both texture and taste, ensuring every batch meets your exacting standards. Explore more about alternative acids1 that might enhance your gummy recipes.

Adding acid too early speeds up gummy gelling.True

Acid lowers pH, accelerating gelling, leading to premature setting.

Encapsulated acids release acidity quickly in gummies.False

Encapsulated acids release acidity slowly, offering control over curing time.

What Role Does Temperature Play in Gummy Curing?

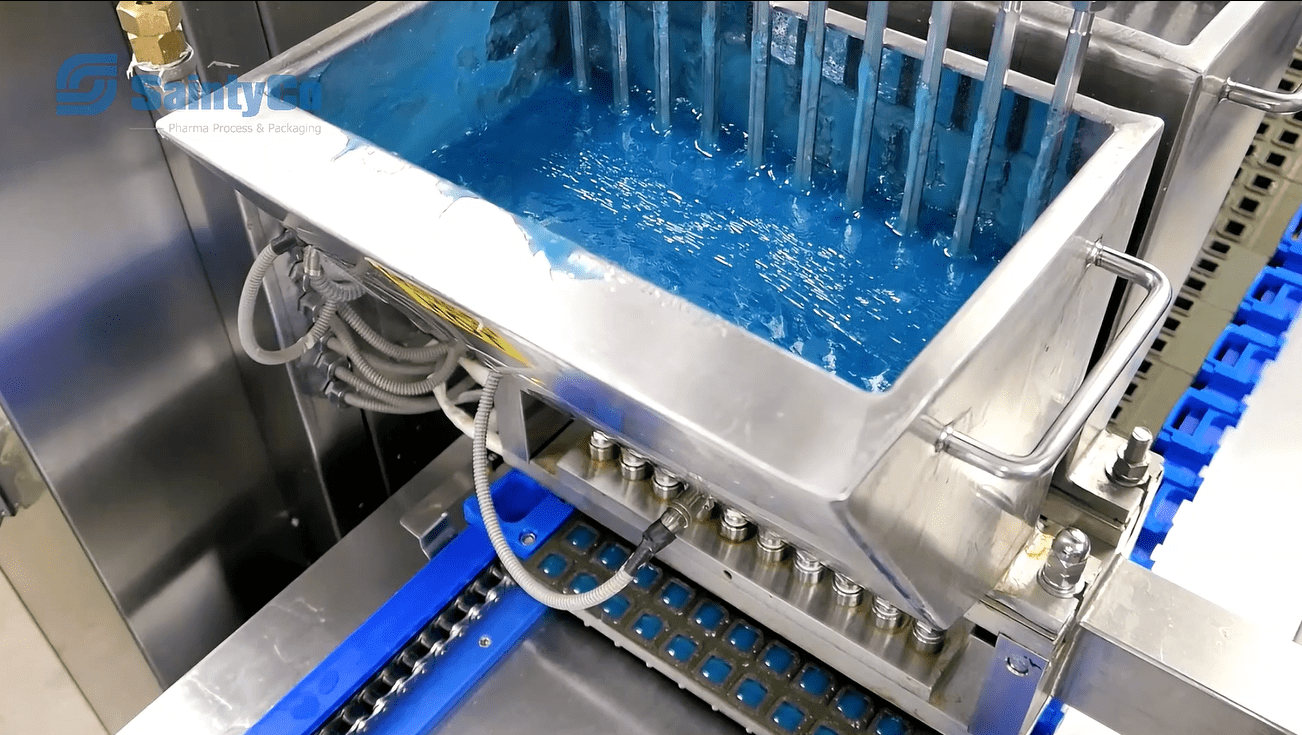

Temperature is vital in gummy curing, affecting viscosity, setting speed, and final texture. Maintaining an optimal temperature during pouring and cooling processes ensures a smooth flow and desired consistency.

The Science Behind Temperature and Gummy Viscosity

Temperature control is crucial during the pouring phase of gummy manufacturing. When the mixture is kept at a higher temperature, specifically between 90-100°C (194-212°F), it maintains a viscosity that allows for easy flow into molds without premature setting. This optimal temperature range ensures the mixture remains manageable, preventing issues like lumps or incomplete mold filling.

For instance, if the temperature drops too soon, the mixture may become too thick to pour evenly, leading to uneven shapes and textures. Maintaining this temperature not only aids in filling but also helps in achieving a consistent gummy texture2 across batches.

Cooling Techniques for Optimal Texture

After pouring, rapid cooling can cause gummies to set too quickly, resulting in a hard or rubbery texture. To avoid this, allow gummies to cool gradually at room temperature rather than immediately refrigerating them. Gradual cooling provides a more controlled setting process, ensuring that the gummies develop their intended chewiness.

To illustrate, imagine pouring hot syrup into a mold and then placing it in a refrigerator. The rapid change in temperature can cause an outer layer to harden quickly while leaving the inside unset. Instead, leaving them at room temperature allows for even cooling and setting.

Temperature Impact on Sugar Concentration

The interaction between temperature and sugar concentration, or Brix level, significantly impacts gummy curing. Higher temperatures can increase evaporation, concentrating the sugar further and affecting the final texture.

Here's a simple breakdown:

| Temperature | Effect on Sugar | Resulting Texture |

|---|---|---|

| High | Increased evaporation | Firmer |

| Low | Less evaporation | Softer or sticky |

Maintaining an optimal temperature balance3 helps manage sugar levels effectively, ensuring a firm yet chewy texture.

Mold Material: Silicone vs. Metal

Different mold materials interact with temperature uniquely. Silicone molds retain heat longer, allowing for slower cooling and curing, which can be beneficial for softer gummies requiring extended curing times.

Conversely, metal molds conduct heat more efficiently, leading to faster cooling and curing. While this might be advantageous for rapid production, careful management of mixture temperature and cooling environment is needed to avoid overly fast setting.

For optimal results when using metal molds, consider adjusting the cooling environment or mixture viscosity to align with your desired texture outcomes.

Choosing the right mold material4 based on your gummy recipe and production goals can greatly influence the final product quality.

Gummies set better at room temperature than in the fridge.True

Gradual cooling at room temperature prevents hard or rubbery textures.

High temperatures decrease sugar concentration in gummies.False

Higher temperatures increase evaporation, concentrating the sugar.

How Does Humidity Affect Gummy Curing and Quality?

Ever wondered why your gummies sometimes end up sticky or hard? Humidity might be the culprit.

Humidity affects gummy curing by influencing moisture retention and drying speed. Optimal humidity levels of 60-65% RH prevent stickiness and ensure consistent texture.

Understanding Humidity's Role in Gummy Production

Humidity plays a crucial role in the gummy curing process, influencing not only how quickly the gummies set but also their final texture and quality. When the humidity levels are too high, gummies can retain excess moisture, leading to a sticky texture and a shorter shelf life. Conversely, low humidity can cause the gummies to dry out too quickly, resulting in a hard and brittle product.

Ideal Humidity Levels for Curing

Maintaining the right humidity level during gummy curing is essential. The recommended range is typically between 60-65% relative humidity (RH). At this level, gummies can cure evenly without losing or gaining too much moisture. A controlled environment helps to achieve the perfect balance of softness and firmness in your gummies.

| Humidity Level | Effect on Gummies |

|---|---|

| High (>65% RH) | Sticky texture, moisture retention |

| Optimal (60-65% RH) | Balanced curing, ideal texture |

| Low (<60% RH) | Rapid drying, hard texture |

Techniques for Controlling Humidity

- Dehumidifiers and Humidifiers: Use dehumidifiers to reduce excessive moisture when RH is too high, or humidifiers to add moisture if the air is too dry.

- Airflow Management: Implement fans to ensure even airflow around your gummies, preventing localized moisture retention or loss.

- Environmental Monitoring: Regularly check the humidity levels using hygrometers to ensure they remain within the optimal range.

Impacts on Flavor and Shelf Life

Humidity doesn’t just affect the texture of your gummies; it also impacts their flavor profile and shelf life. Excessive moisture can dilute flavors, while rapid drying can lead to concentration of taste, potentially overpowering subtle flavors. Additionally, proper humidity control is crucial for preserving the integrity of any added coatings, such as sugar or sour powder.

For more insights on managing the curing environment, explore our comprehensive guide on controlling humidity in food production5. This resource provides detailed strategies to optimize your production setup for consistent results every time.

High humidity makes gummies sticky.True

Humidity over 65% RH retains moisture, causing stickiness.

Low humidity results in soft gummies.False

Low humidity dries gummies quickly, making them hard.

Conclusion

Mastering gummy curing involves balancing ingredients and environment. Apply these strategies for consistent results. Reflect on your process, make adjustments, and enjoy creating perfectly textured gummies. Happy candy-making!

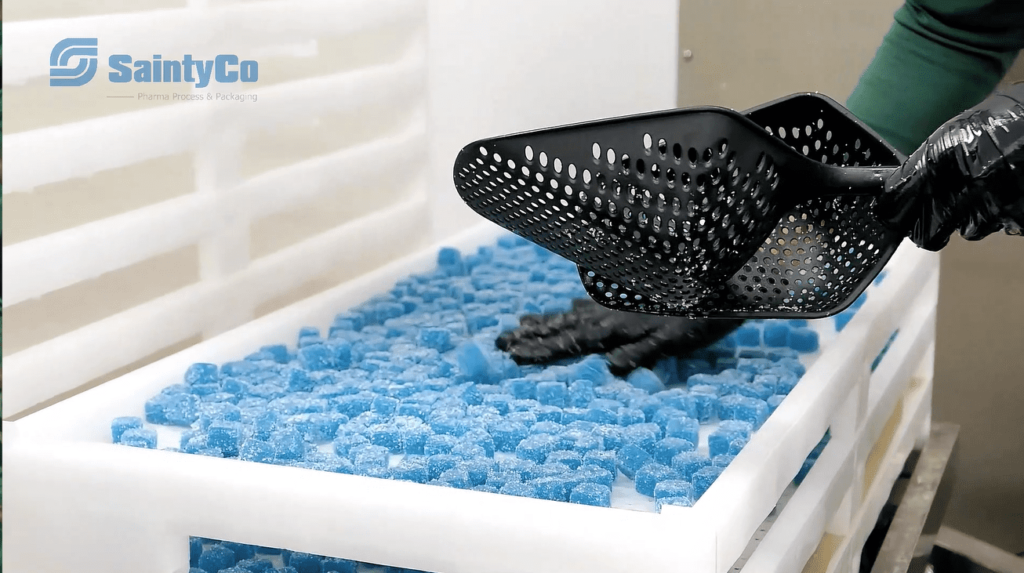

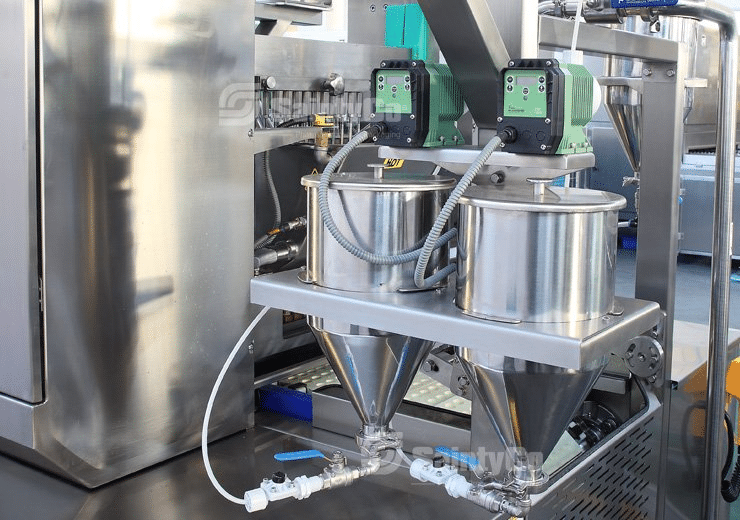

At GummyGenix by SaintyCo, we offer top-of-the-line GummyGenix Depositors designed to eliminate these issues and streamline your production process. With features like automated calibration, smart temperature control, and easy maintenance systems, our machines ensure your gummy production runs without a hitch.

Whether you’re producing traditional gummies or specialized formulations, GummyGenix by SaintyCo is the perfect solution for achieving consistent, high-quality results.

If you’re looking to improve your production efficiency and maintain your equipment with ease, get in touch with GummyGenix by SaintyCo today. We offer tailored support and expert guidance to help you reach your production goals.

-

Discover various acids to improve texture and flavor balance.: Both citric acid and malic acid are common food acids that can be used in gummy candy recipes to add flavor, improve texture, and prevent spoilage. ↩

-

Learn how viscosity influences gummy texture and consistency.: Viscosity can be tested by removing a gummy product from the mold. If it is too fluid, the product will not have solidified due to low ... ↩

-

Discover ideal temperature ranges for achieving perfect candy textures.: 235° F–240° F At this temperature, sugar syrup dropped into cold water will form a soft, flexible ball. If you remove the ball from water, it will flatten like ... ↩

-

Explore how mold material affects candy texture and curing.: Silicone holds heat longer than plastic molds, so it may take longer for your candy to become hard and ready to eat. There's also the chance ... ↩

-

Learn effective strategies for managing humidity in food production environments.: Condensing dehumidifiers are ideal for areas that require a humidity of 50%RH or more and ambient temperatures of above 15°C. Below these levels desiccant ... ↩