Are you a small-scale gummy manufacturer or workshop looking to make a big impact? Your gummy recipe might be a secret gem, but is your packaging doing it justice? Is it meeting the strict compliance standards, packaging hygiene, and product safety? Let’s hop into the world of gummy packaging and learn how to make your candy wrappers shine.

Why Should I Invest in Gummy Packaging Solutions?

The right gummy packaging guarantees product safety and is a crucial marketing tool. But there are more reasons to consider, including:

1. Regulations and Compliance by Region

Different markets have specific regulations regarding gummy packaging, especially for products like CBD gummies, supplements, and other nutraceuticals. Ensuring that your packaging complies with local laws not only prevents legal complications but also reassures consumers about the safety and quality of your products.

United States: FDA Requirements for CBD Gummy Packaging

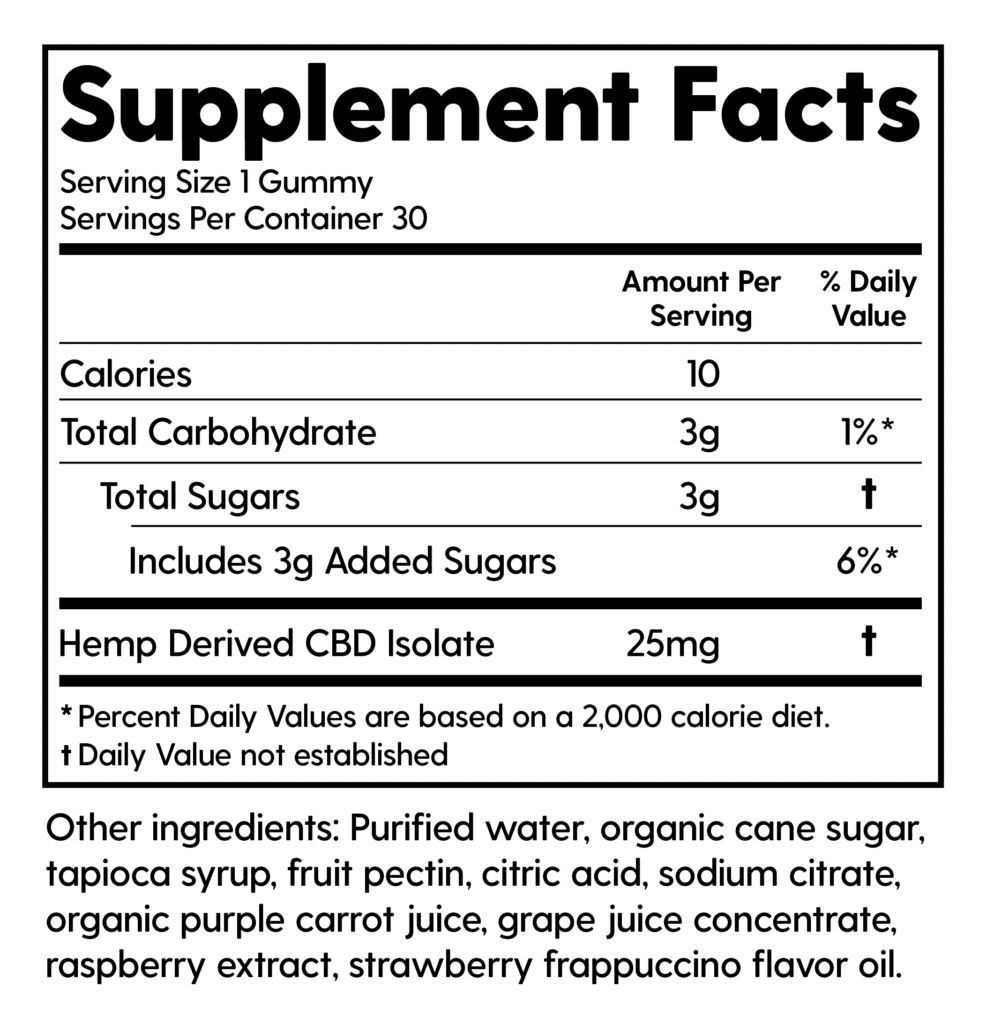

In the U.S., gummy packaging—especially for CBD and nutraceuticals—must comply with FDA regulations to ensure consumer safety and product integrity. The FDA mandates the inclusion of specific information on the packaging, particularly for products marketed as dietary supplements or those containing CBD.

- Labeling: The FDA requires accurate labeling of all ingredients, serving sizes, dosage instructions, and any potential health claims. For CBD gummies, the packaging must explicitly list the CBD content per serving, along with a batch number and clear warnings about the intended use.

- Child-resistant CBD gummy packaging: Under The Poison Prevention Packaging Act (PPPA), all cannabis products must be sold in child-resistant packaging (CRP). Multi-use packaging must be resealable and remain child-resistant after opening. Single-use products must have a child-resistant seal and be clearly marked as "not child-resistant after opening".

- Tamper-evident features: The FDA also encourages tamper-evident packaging, ensuring that consumers are aware if a product has been tampered with before purchase.

.

.

European Union: Packaging and Sustainability Directives

In the European Union, packaging requirements are not only focused on consumer safety but also sustainability. The EU has stringent rules regarding the recyclability of packaging materials and the use of single-use plastics.

- Eco-friendly materials: The European Commission's Packaging and Packaging Waste Directive (PPWD) enforces strict guidelines about using recyclable or reusable packaging. For gummy products, this means opting for packaging materials that have a minimal environmental impact, such as biodegradable films or recyclable plastic.

- Nutraceutical labeling: Similar to the U.S., the European Food Safety Authority (EFSA) requires accurate labeling of ingredients, health claims, and potential allergens. Packaging for CBD gummies must clearly indicate cannabinoid content, serving size, and any applicable health warnings.

- Child-proofing for CBD gummies: Child-resistant packaging is required across the EU for products containing CBD or other controlled substances.

.

Canada: Health Canada Regulations for CBD Gummy Packaging

In Canada, the regulation of cannabis products, including gummies, is governed by Health Canada under the Cannabis Act and Cannabis Regulations. For gummy packaging, the focus is on child safety, proper labeling, and tamper-proof features.

- Child-resistant packaging: Packaging for CBD/THC-infused gummies, or CBD gummy packaging, must meet stringent child-resistant packaging requirement. This is enforced under the Cannabis Act to prevent accidental ingestion.

- Plain packaging requirements: In Canada, CBD and THC products must adhere to strict plain packaging rules. Branding, logos, and other design elements are severely restricted to avoid promoting cannabis products to minors.

- Labeling for potency: Health Canada mandates that the packaging clearly display the THC/CBD content, dosage, and any relevant health warnings.

.

2. Labeling requirements

Proper labeling of CBD and vitamin gummy packaging can’t be overstated. You must include essential information such as key ingredients, serving size, warnings, CBD content, etc. By accurately labeling gummies, your brand demonstrates a commitment to consumer safety while protecting it from potential legal issues.

3. Protection and hygiene

Since these delicate treats are susceptible to contamination, you should invest in quality gummy packaging. This protective barrier shields them from dust, dirt, and moisture and prevents damage or contamination. That way, your products will reach consumers in perfect condition, maintaining your reputation for excellence.

.

Elevate Your Brand with Modern Gummy Packaging Trends

Today's gummy packaging goes beyond functionality; it plays a critical role in shaping the consumer experience and building brand loyalty. Modern packaging trends are heavily influenced by consumer preferences for sustainability, transparency, and personalized experiences.

.

1. Eco-Friendly Gummy Packaging

Consumers are increasingly choosing brands that demonstrate a commitment to sustainability for a gummy bear package. Recent studies show that over 50% of U.S. consumers are willing to pay a premium for eco-friendly packaging. According to the Flexible Packaging Association (FPA), flexible pouches now account for over 20% of the total packaging market, highlighting their increasing adoption in gummy manufacturing due to their versatility and lower environmental impact.

- Example: Brands like XYZ Gummies saw a 15% increase in customer loyalty after switching to biodegradable materials.

.

2. Transparent and Minimalist Gummy Packaging Designs

Consumers value transparency, especially in food and nutraceutical products. Clear and minimalist designs that prominently display ingredients, nutritional information, and health benefits help build trust with your audience. This approach is not only visually appealing but also aligns with modern wellness trends.

- Example: ABC Wellness Gummies uses transparent packaging with clear ingredient lists, resulting in higher customer engagement and trust.

.

3. Personalized and Interactive Gummy Bear Packaging

To foster deeper connections with your audience, consider offering personalized packaging. Adding elements like custom labels, QR codes, or limited-edition designs can create a memorable consumer experience. This strategy is particularly effective for niche markets such as wellness or CBD products.

- Example: CBD Treats Co. offers custom packaging options where consumers can select flavors or add their name, driving repeat purchases and social media engagement.

4. Engaging and Playful Gummy Bear Individual Package Designs

For brands targeting younger consumers or seeking to stand out on crowded shelves, interactive and playful packaging can be a powerful tool. Some brands use packaging designs that include games, toys, or collectible items, turning unboxing into a fun experience.

- Example: FunTime Gummies incorporates hidden compartments and pop-up designs, which increase repeat purchases and customer engagement.

.

5. Health and Wellness-Focused Gummy Packaging Designs

With the rise of health-conscious consumers, wellness-focused gummy brands are turning to packaging that communicates the natural, organic benefits of their products. Using natural color palettes, clean typography, and illustrative designs can help emphasize the health benefits of your gummies.

- Example: GreenVital Gummies uses eco-friendly, minimalist packaging that reflects their organic ingredients, resulting in a 20% growth in sales.

.

.

What Is the Safest Gummy Packaging for My Products?

The safest gummy packaging depends on the product type, target market, environmental concerns, and budget. Below are some commonly used options:

1. Plastic bags for Gummy Packaging

Polypropylene plastic is a typical material used for most plastic bags for gummy bear packaging. You can find heat-sealed and resealable plastic bags for various products, including candy gummies, supplements, and vitamins. The bags are fillable by weight or quantity and sealed for an airtight closure to prevent moisture.

Pros

● Cost-effective

● Lightweight

● Easy to seal

● Versatile in size

Cons

● Susceptible to punctures

● Not ideal for large quantities.

.

2. Plastic and Glass Bottles for Edible Gummy Packaging

Bottles are another cost-effective CBD gummy packaging option you can easily source. For CBD gummy packaging, glass and plastic bottles are ideal for maintaining product potency and preventing contamination. They are available in different shapes and sizes, including large, medium, and small jars. Both glass and plastic bottles can be opened and re-closed for reusage. Bottles are ideal for moisture control and are tamper-proof, making them ideal for child-resistant gummies.

.

Pros

● Resealable

● Protects gummies from damage

● Visually appealing

● Suitable for various sizes

Cons

● Higher cost than plastic bags

● Not as eco-friendly as some options.

.

3. Pouches for Gummy Packaging

Pouches combine the benefits of bags and bottles, offering a flexible, resealable, and attractive gummy packaging option. They are available in different materials and sizes and have good product visibility. Besides, pouches can handle moisture control and prevent product tampering.

Pros

● Easy display

● Resealable

● Lightweight

● Cost-effective.

Cons

● Potential for punctures.

.

4. Cans for Gummy Packaging

Cans are known for superior product protection against moisture, light, and oxygen. Studies such as those published in the Journal of Food Science have demonstrated the superior barrier properties of packaging materials like cans, offering excellent protection against environmental factors that could compromise product quality.

Pros

● Offers superior protection.

● Prevents light and moisture penetration.

● Ideal for long shelf life.

Cons

● High cost

● Heavier.

.

5. Cartons for Gummy Packaging

Carton gummy packaging uses tough paper materials, making it easily disposable. The carton paper is easily customized into various shapes and sizes to meet different aesthetic needs. You can make them into rectangular or square boxes, pentagonal shapes, and more styles. They have poor moisture control, are easy to tamper, and are less child-resistant.

Pros

● Provides excellent product protection

● Versatile for branding

● Recyclable.

Cons

● Less convenient for consumers

● Not suitable for all gummy types.

.

Here is a comparative table with detailed pros and cons for each type of gummy packaging option:

| Packaging Type | Pros | Cons | Best Suited For |

| Plastic Bags | - Cost-effective- Lightweight- Easy to seal- Versatile in size | - Susceptible to punctures - Not ideal for large quantities | Small to medium-sized businesses with low to moderate budgets. |

| Plastic and Glass Bottles | - Resealable- Protects gummies from damage- Visually appealing- Child-resistant | - Higher cost than plastic bags - Not as eco-friendly as some options | Premium products requiring tamper resistance and moisture control. |

| Pouches | - Easy display- Resealable- Lightweight - Cost-effective | - Potential for punctures | Brands focusing on product visibility and mid-range packaging costs. |

| Cans | - Superior protection against moisture, light, and oxygen - Long shelf life | - High cost - Heavier | Premium and sensitive gummy products needing extended shelf life. |

| Cartons | - Excellent product protection - Versatile for branding - Recyclable | - Poor moisture control - Easy to tamper with | Environmentally conscious brands with focus on aesthetics and sustainability. |

Not sure which packaging type is right for your gummy products? Contact our experts for a free consultation and find the best solution for your business.

.

Which Gummy Packaging Machine is Best for My Business?

Your gummy packaging machine is the heart of your packaging operation. You should consider the machine’s capabilities, labor requirements, safety levels, and maintainability and opt for a model that matches your gummy type, production volume, and packaging style. Read the next section to find out which gummy packaging machine perfectly suits your business.

.

GummyGenix: Best Gummy Packaging and Manufacturing Solution

With over 20 years of experience in the phara-grade packaging automation industry, GummyGenix has helped brands globally streamline their production lines and achieve FDA compliance. We specialize in designing, manufacturing, integrating, and servicing packaging solutions for food and pharmaceutical products, ensuring that your packaging meets industry standards for safety, quality, and efficiency. We offer semi and fully-automated gummy packaging equipment for edibles, supplements, and confectionary, ideal for small shops and large-scale manufacturing.

These gummy packaging machines include:

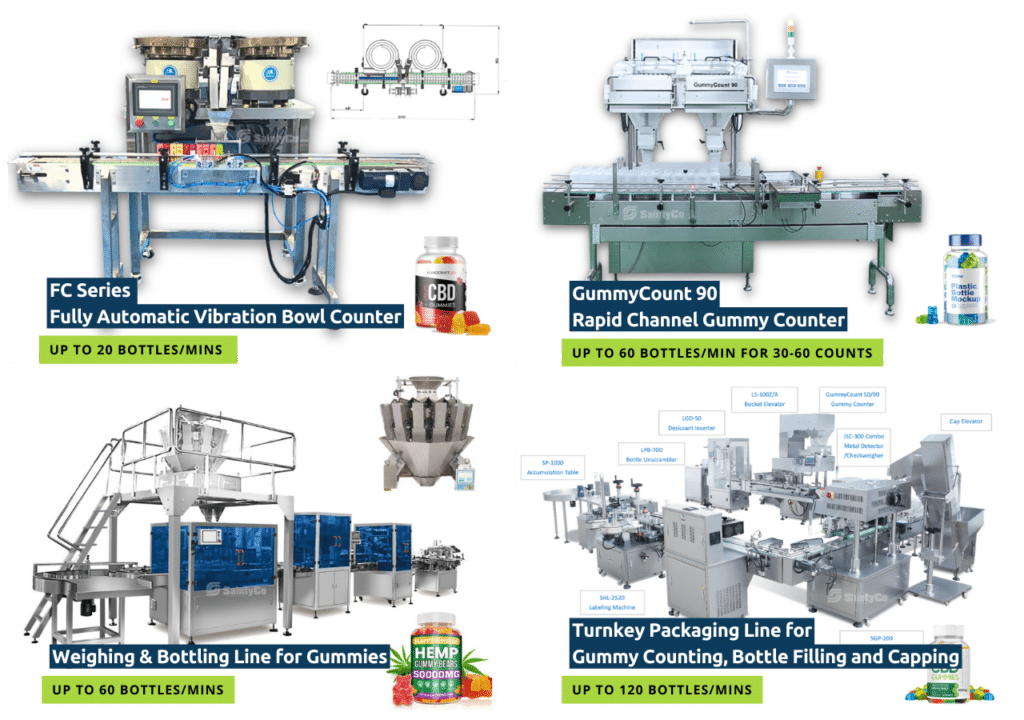

1. Gummy Counting & Bottle Filling Machines

These gummy packaging equipment are designed specifically for counting and filling containers to boost your gummy production efficiency.

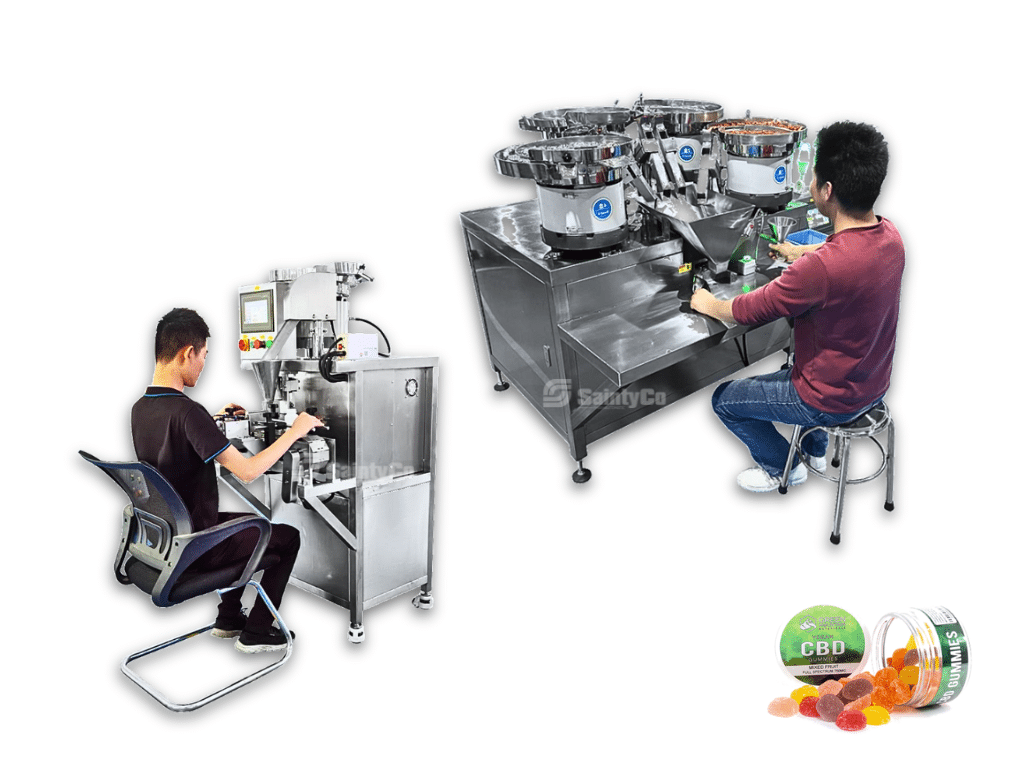

A. Gummy Packaging Machines for Small-Scale Manufacturers

If you're just starting out or operate a small gummy production workshop, the focus should be on balancing cost-efficiency with production output.

SC V1/SC V4 Semi-Automatic Vibration Bowl Counter is an ideal entry-level solution. It offers reliable output at a manageable price point and can fill up to 10 bottles per minute. This machine requires manual assistance but provides enough flexibility for small-batch production without compromising on quality.

- Why Choose This Machine?

- Affordable for startups

- Compact and space-saving

- Easily adjustable for small gummy batches

- Best suited for businesses producing up to 10 bottles per minute

.

.

B. Gummy Packaging Machines for Medium-Scale Manufacturers

If your business has grown to meet moderate demand, you'll need a more automated system to increase efficiency. The FC Series Fully Automatic Vibration Bowl Counter is a great fit for businesses looking to scale. It handles up to 20 bottles per minute with minimal manual intervention, making it perfect for mid-sized gummy production operations.

- Why Choose This Machine?

- Fully automated, reducing labor costs

- Ideal for scaling production

- Flexible bowl configurations for various gummy sizes

- Best suited for businesses producing up to 20 bottles per minute

.

.

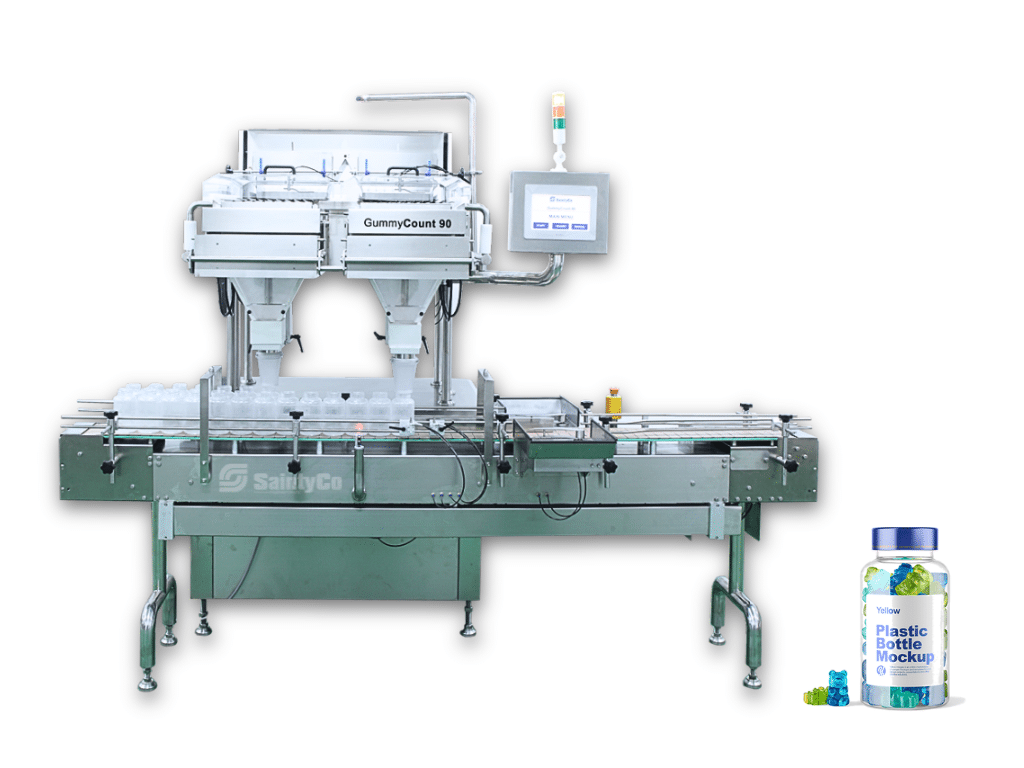

C. Gummy Packaging Machines for Large-Scale Manufacturers

High-volume manufacturers should consider fully automated systems capable of handling large production outputs with precision and minimal downtime. The GummyCount 90 Rapid Channel Gummy Counter is designed for large-scale operations, capable of filling up to 60 bottles per minute with excellent accuracy. For businesses that need to push efficiency further, the Turnkey Packaging Line for Gummy Counting, Bottle Filling and Capping offers fully automated packaging solutions, handling up to 120 bottles per minute.

- Why Choose These Machines?

- Advanced automation reduces operational costs over time

- Can handle high volumes without sacrificing quality

- Built-in systems for moisture control and tamper-proof packaging

- Best suited for businesses producing 60-120 bottles per minute

By selecting the appropriate machinery based on your current scale, you can ensure that your gummy packaging process is both cost-effective and future-proof.

.

2. Weighing & Bottling Line for Gummies

This Weighing & Bottling Line for Gummies is a fully automated gummy packaging machine designed for large-scale production. It can handle up to 60 bottles/minute without overfilling or underfilling while preserving the appearance of each piece. You can use it to improve bottle unscrambling, labeling, weighing, filling, capping, and induction sealing.

.

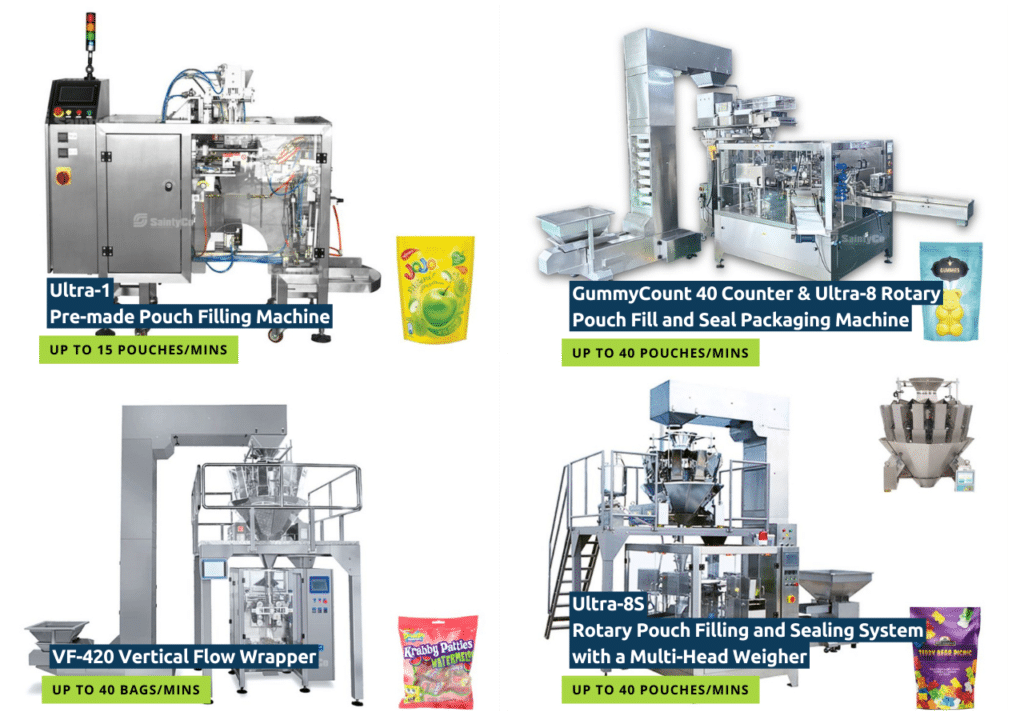

3. Gummy Counting & Pouch Filling Equipment

Another type of GummyGenix gummy packaging solution offers machines capable of counting with fill-and-seal operations. They include:

a. The Ultra-1 Pre-Made Pouch Filling Machine

This single-station unit can handle up to 15 pouches/minute from pickup to opening, filling, and sealing. Its compact design is perfect for small to medium production lines. You can use it for large pouches, including those with significant weights.

b. GummyCount 40 Counter & Ultra-8 Rotary Pouch Fill and Seal Packaging Machine

This gummy packaging machine from GummyGenix is designed specifically for high-stickiness gummies. It can fill and seal up to 40 pouches per minute, making it perfect for large volumes for medium-scale operations.

.

.

In fact, a mid-sized gummy manufacturer saw a 35% improvement in packaging efficiency by switching to GummyGenix’s automated solutions. By incorporating the GummyCount 40 Bulk Counter, Ultra-8 Premade Pouch Filling Machine, and Z-Type Bucket Chain Gummy Loader, the company was able to meet growing demand while maintaining product consistency and regulatory compliance.

.

4. Gummy Weighing & Pouch Filling Equipment

In this category, we have the Ultra-8S Rotary Pouch Filling and Sealing System with a Multi-Head Weigher. The gummy packaging machine can fill up to 40 pouches/minute for high volumes that involve weighing and sealing various pouch types. It can be used for gummy production, requiring high throughput and quality consistency.

.

.

5. Gummy Weighing & Vertical Wrappers (VFFS)

You can also enhance your gummy production with the VF-420 Vertical Flow Wrapper for full automation from start to finish. It can handle 30 to 80 bags per minute, offering feeding, closing, sealing, date printing, etc. Its compact design is ideal for candy workshops with minimal space or start-ups looking to upscale.

.

6. Horizontal Flow Wrapper Machine for Individual Gummies

If your production involves wrapping for individual gummies, the HSB-400/800/1200 High-Speed Bowl Wrapper is designed for you. The unit can be integrated into small and large-scale gummy production lines, wrapping up to 1200 gummy pieces per minute.

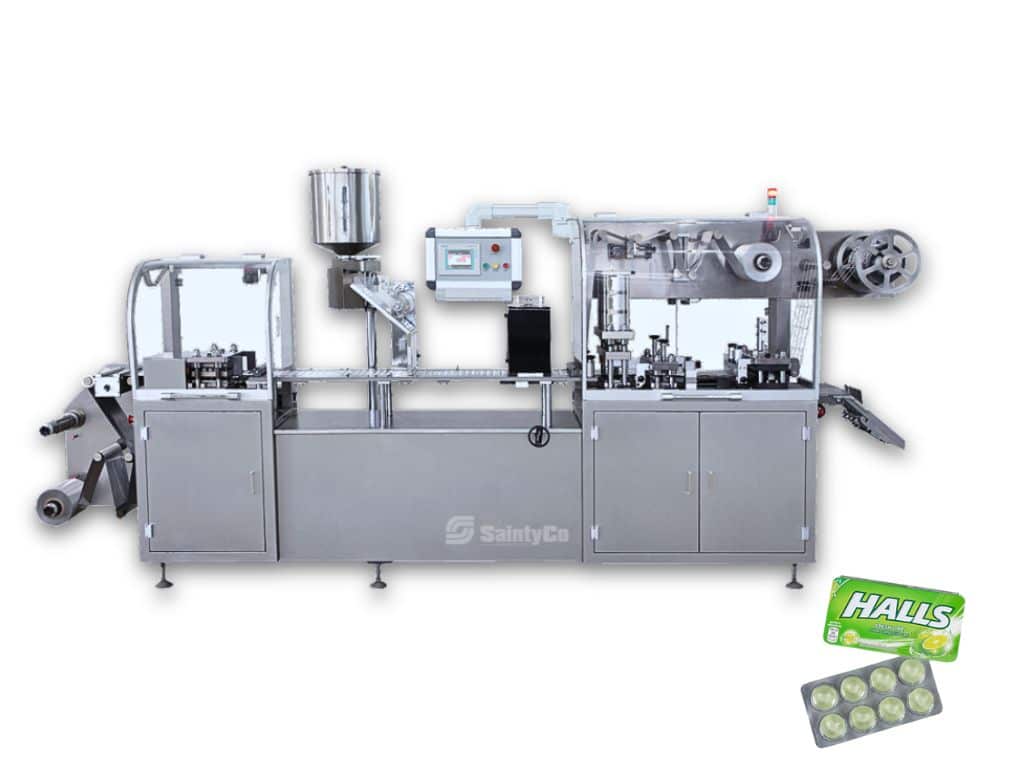

7. Blister Packing Machine for Gummies

For businesses that make gummies for medical purposes, GummyGenix offers the BP-120/150/260 Blister Packing Machine for Gummies. It is designed for gummies that require product safety and an extended shelf life. We have also designed the CBD gummy packaging solution for food industries and pharmaceuticals of all sizes.

Here is a comparative table with detailed pros and cons for each type of gummy packaging machine, along with recommendations for which industries and scales of production they are best suited for:

| Machine Type | Pros | Cons | Best Suited For | Scale of Production |

| SC V1/SC V4 Semi-Automatic Vibration Bowl Counter | - Compact design - Cost-effective - Suitable for small batches - Manual assistance enhances precision | - Slower output - Requires continuous manual operation | Small candy workshops or startups | Small-scale production (up to 10 bottles per minute) |

| FC Series Fully Automatic Vibration Bowl Counter | - Minimal manual intervention - Adapts to different gummy types - Suitable for scaling up production | - More expensive than semi-automatic machines - Limited customization options | Medium-sized manufacturers looking to scale | Small to medium-scale production (up to 20 bottles per minute) |

| GummyCount 90 Rapid Channel Gummy Counter | - High speed and accuracy - Handles large volumes - Adjustable speeds and head heights | - Higher cost - Requires more space for installation | Medium to large-scale manufacturers | Medium to large-scale production (up to 60 bottles per minute) |

| Turnkey Packaging Line for Gummy Counting, Bottle Filling, and Capping | - Fully automated - Seamless integration with existing lines - High precision and efficiency | - High upfront cost - Requires more space and maintenance | Large-scale gummy manufacturers looking for full automation | Large-scale production (up to 120 bottles per minute) |

| Ultra-1 Pre-Made Pouch Filling Machine | - Compact - Suitable for large pouches - Affordable for small to medium operations | - Lower speed - Limited to pre-made pouches | Small to medium manufacturers handling larger pouches | Small to medium-scale production (up to 15 pouches per minute) |

| GummyCount 40 Counter & Ultra-8 Rotary Pouch Fill and Seal Machine | - Handles high-stickiness gummie s - High volume throughput - Minimal manual intervention | - Expensive - Requires significant space and maintenance | Medium-scale manufacturers with sticky products | Medium-scale production (up to 40 pouches per minute) |

| Ultra-8S Rotary Pouch Filling and Sealing System with Multi-Head Weigher | - High-speed weighing and sealing - Ensures consistency and accuracy - Suitable for various pouch types | - High initial cost - Requires extensive setup and calibration | Large-scale manufacturers requiring consistency | Large-scale production (up to 40 pouches per minute) |

| VF-420 Vertical Flow Wrapper | - Full automation - Compact design - Handles various bag types - Fast output | - Requires calibration for different bag types - Limited customization options | Startups and small workshops looking to scale quickly | Small to medium-scale production (30 to 80 bags per minute) |

| HSB-400/800/1200 High-Speed Bowl Wrapper | - Wraps individual gummies quickly - Integrates well into existing lines - Suitable for high-volume production | - Expensive upfront cost - Requires technical setup and maintenance | Large-scale gummy production lines | Large-scale production (up to 1200 pieces per minute) |

| BP-120/150/260 Blister Packing Machine for Gummies | - Excellent for medical gummies - Provides long shelf life - Tamper-proof | - Higher cost - Not suitable for all types of gummies | Pharmaceutical and high-end nutraceutical manufacturers | Small to medium-scale production (varies by model) |

Summary of Best-Suited Industries and Production Scales

- Small-Scale Production: SC V1/SC V4 Semi-Automatic Vibration Bowl Counter, Ultra-1 Pre-Made Pouch Filling Machine, VF-420 Vertical Flow Wrapper.

- Medium-Scale Production: FC Series Fully Automatic Vibration Bowl Counter, GummyCount 40 Counter & Ultra-8 Rotary Pouch Fill and Seal, Ultra-8S Rotary Pouch Filling and Sealing System.

- Large-Scale Production: GummyCount 90 Rapid Channel Gummy Counter, Turnkey Packaging Line, HSB-400/800/1200 High-Speed Bowl Wrapper, BP-120/150/260 Blister Packing Machine.

.

Looking for a packaging machine tailored to your production needs? Let us help you design a customized solution. [Customize Now]

.

Cost-Efficiency and Maintenance Considerations

While fully automated systems like the GummyCount 90 GummyCounter may have higher upfront costs, they offer long-term cost savings in labor reduction and efficiency. These machines are designed for easy maintenance, requiring fewer operator hours and reducing the chances of production halts due to technical issues.

Here’s how to think about cost-efficiency and maintenance:

- Upfront Costs vs. Long-Term Savings: Semi-automatic systems are often more affordable initially, making them an attractive choice for startups. However, fully automated systems offer greater long-term savings by reducing the need for manual intervention, cutting labor costs, and speeding up production.

- Ease of Maintenance: Fully automated systems like the GummyCount 90 and the Turnkey Packaging Line are designed with minimal maintenance requirements. They feature self-diagnostic tools that alert operators to potential issues before they cause downtime, ensuring continuous operation.

- Space Requirements and Installation: Some advanced systems may require more space and have higher installation costs. It's essential to factor in the available floor space and any necessary modifications to your production facility when considering larger-scale systems.

.

By weighing these factors—upfront costs, long-term savings, and ease of maintenance—you can choose a gummy packaging machine that aligns with your business's goals while remaining budget-conscious.

.

Ready to upgrade your packaging process? Explore GummyGenix’s range of automated packaging machines tailored for every scale of production.

.

Conclusion: How to Choose the Right Gummy Packaging

Choosing the best gummy packaging ensures product safety, compliance, and enhanced branding. To make the best decision for your gummy business, consider the following key factors:

- Compliance with Regulations

Whether you're in the nutraceutical, CBD, or confectionary sector, your packaging must meet regional and industry-specific regulations. Ensure that you’re investing in child-resistant, tamper-evident packaging solutions that also meet labeling and hygiene standards. - Scalability

Assess your current production volume and future growth plans. If you're starting small but planning to scale, investing in semi-automatic machines like the SC V1 is a great way to start. As you scale, transitioning to fully automated systems like the GummyCount 90 or the Turnkey Packaging Line will help you meet increased demand while maintaining efficiency. - Design Appeal and Brand Representation

The packaging should not only protect your gummies but also make a lasting impression on your customers. Choose packaging solutions that align with your brand values and appeal to your target market. Whether it’s eco-friendly materials, sleek designs, or packaging that highlights product transparency, the right choice can elevate your brand.

.

By following these steps, by selecting the right gummy packaging machine and ensuring compliance with CBD gummy packaging standards, your business can achieve higher production efficiency and consumer trust.

.

You can order GummyGenix gummy packaging machines to improve your production processes. We offer equipment customization for small, medium, and large-scale gummy production. You should contact our sales team now for your orders!

.

FAQs

1. How can I prevent gummies from sticking to the gummy bear package?

You can combat gummy stickiness using packaging materials with low moisture absorption, such as aluminum foil, and incorporate desiccants into the packaging. Moreover, you should adjust the sugar-to-gelatine ratio or add anti-sticking agents like rice flour to reduce the chances of sticking to the CBD gummy packaging. Lastly, ensure your gummies have proper storage.

.

2. What factors should I look for when choosing CBD gummy packaging?

There are several factors to consider, including protecting your gummy’s integrity. For instance, you should use airtight packaging for CBD gummies to preserve their potency and quality. You must also consider complying with local regulations such as child-resistant closures and clear labeling. Design a package that reflects your brand’s identity and is environment-friendly.

Here's a checklist to guide you through the decision-making process:

Step-by-Step Guide:

- Compliance with Regulations:

- Child-Resistant Packaging: CBD gummies, especially those sold in markets like the U.S., must be packaged in child-resistant containers to prevent accidental ingestion.

- Clear Labeling: Ensure that your packaging includes required legal information such as the CBD content per serving, batch numbers, warnings, and ingredients. This helps protect your business from legal issues and ensures consumer safety.

- Tamper-Evident Features: Incorporate tamper-evident seals to prevent product tampering and ensure product integrity.

- Packaging Material:

- Airtight and Moisture Resistant: CBD gummies are sensitive to environmental conditions. Packaging should be airtight to protect against moisture, which can degrade the product's quality and potency.

- Opaque Materials: Consider using packaging that protects against light exposure, as UV rays can break down cannabinoids like CBD, reducing effectiveness.

- Brand Representation:

- Appealing Design: Packaging is a powerful marketing tool. Ensure that the design aligns with your brand identity and stands out on the shelf. Consider eco-friendly materials if your brand focuses on sustainability.

- Target Market: Match your packaging style to your market. For example, sleek and minimalist designs may appeal to wellness-conscious consumers, while playful designs may resonate with a younger demographic.

- Functionality:

- Resealability: Many consumers appreciate packaging that can be resealed to keep the gummies fresh after opening.

- Durability: Choose packaging that can withstand shipping and handling without being easily damaged or punctured.

- Cost Efficiency:

- Material Cost vs. Value: Balance the cost of the packaging with the value it adds to your product. Higher-end CBD products might justify premium packaging, while economy lines may need cost-effective solutions.

Checklist:

- Child-resistant and tamper-evident

- Airtight and moisture-resistant

- Compliant with local regulations (e.g., clear labeling)

- Packaging protects against light exposure (opaque materials)

- Aligns with brand identity and target market

- Resealable and durable for consumer convenience

- Cost-effective without compromising product integrity

.

3. What can I do to prevent gummy packaging from being tampered with?

You should implement anti-tampering measures such as tamper-evident seals or labels that are difficult to remove without leaving visible evidence. Such seals can deter potential tampering and assure product authenticity.

.

4. What design trends should I consider for a gummy bear individual package?

Some of the best design trends for individual gummy bear packaging include sustainability, transparency, and minimalism. Other trendy designs incorporate interactive elements such as games and hidden messages and allow you to personalize them to your preferred style.

.

5. What information should I print on gummy packaging?

Your gummy packaging should contain clear and informative details about your products. You should add your brand name, ingredients, nutritional chart, and batch number. Other critical information includes product precautions, dosage, and expiry date.

.

6. What maintenance does a gummy packaging machine require?

Regular maintenance of a gummy packaging machine is essential to ensure longevity and optimal performance. Most machines require periodic cleaning, lubrication, and calibration. Here’s a basic guide:

- Cleaning: Machines handling food products like gummies should be cleaned frequently to maintain hygiene. This includes removing any leftover gummy residues and wiping down contact parts.

- Lubrication: Key moving parts such as conveyor belts, motors, and gears need to be lubricated according to the manufacturer's guidelines to avoid wear and tear.

- Calibration: Periodically check machine settings (e.g., for weight, size, and fill level) to ensure accurate performance. Miscalibration can lead to faulty packaging or product damage.

- Part Replacement: Keep spare parts on hand for common wear items like seals, belts, and sensors. Regularly inspect and replace any components showing signs of damage.

.

7. How do I choose between different automation levels?

Selecting the right automation level depends on your production scale, budget, and long-term goals:

- Semi-Automatic Systems: Ideal for small-scale production or startups. These systems often require manual loading or assistance but are more affordable and compact.

- Fully Automatic Systems: Best suited for mid- to large-scale manufacturers. These machines handle the entire packaging process with minimal human intervention, boosting output and reducing labor costs.

- Turnkey Solutions: For large-scale operations, turnkey systems integrate multiple machines, from counting and filling to capping and labeling, providing end-to-end automation. These are more expensive but can drastically reduce operational costs over time.

.

8. What are the ongoing operational costs of gummy packaging machines?

Ongoing costs will vary depending on the type of machine and your production volume, but here are some key expenses to consider:

- Energy Consumption: Fully automated machines typically consume more electricity, so consider the cost of powering your equipment.

- Maintenance Costs: Regular maintenance and the occasional need to replace parts (e.g., belts, nozzles, sensors) can add to your operational costs.

- Labor Costs: Semi-automatic machines require more manual labor than fully automated ones, so while the initial machine cost is lower, ongoing labor costs will be higher.

- Consumables: Items like lubricants, cleaning agents, and packaging materials (e.g., pouches, bottles) also contribute to ongoing expenses.