Gelatin-free gummy production is hitting its stride, especially among brands eyeing the vegan and vegetarian markets. If you're steering the ship at a gummy company, investing in specialized machinery for gelatin-free products can significantly boost your efficiency and enhance the quality of your treats. With a rising wave of consumers clamoring for healthier and more inclusive candy choices, tapping into this segment could sweeten your profit margins.

To create gummies without gelatin, you'll need equipment designed for alternative gelling agents like pectin or agar. Essential machinery includes cooking systems for precise temperature control, depositing machines for accurate dosing, and cooling tunnels to ensure proper setting.

Let's explore the essential equipment and steps for making high-quality gummies without gelatin.

Introduction to Gelatin

The main sources of gelatin, a protein made from animal collagen, are the bones, skin, and connective tissues of pigs and cows. When heated and then cooled, it turns into a gel, which is why the culinary industry uses it as a common thickening. Gelatin's melting point, which ranges from 89.06°F to 93.56°F (31.7°C to 34.2°C), can be problematic in warmer locations because it can cause gummy products to melt more quickly than an ice cream cone on a summer day, requiring transportation to be temperature-controlled. Gelatin is also off-limits to vegetarians, vegans, and other religious dietary watchers due to its animal-based composition, which creates ethical concerns.

.

.

Why Choose Gelatin-Free Gummies?

Consumer Demand and Dietary Preferences

- Surging Popularity: Gelatin-free gummies are climbing the popularity charts due to various dietary preferences and limitations.

- Vegan-Friendly Choices: With a spike in veganism, gelatin-free options are becoming more desirable.

- Allergy-Safe: These gummies cater to those with specific allergies or dietary needs, expanding your market reach.

- Elevate Your Brand: Introducing gelatin-free selections can enhance your brand's attractiveness, particularly to those focused on health and wellness.

Ethical and Dietary Concerns

- Consumers choose gelatin-free gummies to promote ethical and compassionate food production.

- Gelatin made from pig is not allowed for persons following halal or kosher diets. Gelatin-free gummies offer an alternative.

- Plant-based diets offer several health benefits, leading to a growing demand for plant-based items such as confectioneries.

.

.

Advantages of Pectin Over Gelatin

- Temperature Stability: Gelatin-based gummies melt in hot weather and stick together, often requiring temperature-controlled trucks for distribution, which increases costs. Pectin-based gummies, with a melting point of around 200ºC, can be shipped during summer without the risk of melting.

- Textural Benefits: Pectin produces gummies with a soft, viscous body, exceptional mouthfeel, rapid flavor release, clean-cut texture, and glossy appearance.

- Consumer Expectations: Pectin meets consumer expectations regarding appearance, taste, and texture. It also allows for reduced sugar levels while maintaining desired sensory properties.

.

Base Ingredient Gelatin Alternatives

Agar-Agar

- Source: Derived from red algae.

- Properties: Forms a firm, brittle gel that is stable at room temperature, suitable for gummies needing to maintain shape in warmer conditions.

- Melting Point: Sets at 32-40°C (89.6-104°F) and melts at 85°C (185°F), offering a higher melting point than gelatin.

- Texture: Ideal for creating a firmer texture in gummies.

.

.

Carrageenan

- Source: Derived from certain types of red seaweed.

- Properties: Known for forming gels with various textures, from soft to firm.

- Usage: Often combined with other gelling agents to achieve the desired texture and stability in gummy products.

.

.

Choosing the Right Gelling Agent: Pectin vs. Agar

Selecting between pectin and agar depends on the desired gummy texture and production requirements. Pectin is ideal for a softer, jelly-like consistency, while agar produces a firmer, more robust gummy. Testing both agents can help determine the best fit for your products. Consider factors like setting time, temperature sensitivity, and flavor compatibility when choosing your gelling agent.

.

Melting Point Considerations

Understanding the melting point of your gelling agents is critical to your production process. Gelatin's melting temperature ranges from 89.06 to 93.56°F, while pectin-based gummies have a higher melting point of around 200ºC. This greater melting point enables them to survive higher temperatures during transportation and storage. Contact your ingredient supplier to get the recommended melting point for their specific gelling agent.

.

Non-Gelatin Gummy Production: Key Considerations

When using a gelatin substitute, you’ll need to become well-versed in your ingredient of choice. Key considerations include ingredient ratios, cooking process, and cooking temperature.

Ingredient Ratios

- Adjustments: Plant-based gelling agents often require recipe adjustments to achieve the desired characteristics in your gummy products.

Cooking Process

- Compatibility: Different base ingredients necessitate different cooking processes. For instance, pectin-based gummies can’t be reworked if they fail to set initially, whereas gelatin can sometimes be reprocessed. Ensure your equipment is compatible with your chosen ingredients and discuss any questions with your equipment provider.

Cooking Temperature

- Optimization: Different base ingredients need specific temperatures for melting and cooling. Fine-tuning your temperature settings and timing of each cooking phase is essential.

.

.

Step-by-Step Process for Making Gelatin-Free Gummies

- Gathering Ingredients: Start by measuring the right amounts of fruit juice, sweeteners, and the gelling agent of your choice. Using high-quality, natural components will not only boost the flavor but also the allure of your gummies.

- Cooking: Warm up the mix in your cooking system to completely melt the gelling agent. It's vital to keep the heat consistent and stir non-stop to avoid any scorches and ensure everything blends smoothly.

- Depositing: Next, pour the blend into molds using depositing machines. Make sure the molds are clean and well-oiled to dodge any sticky situations and make popping the gummies out a breeze.

- Cooling: Let the gummies firm up in a cooling tunnel. Fine-tuning the cooling duration and temperature is key to nail that perfect chewy texture.

- Packaging: Finally, when the gummies are set, whisk them off to be packaged with automated systems. Choose packaging materials that are safe for food and strong enough to withstand moisture and air.

.

Essential Equipment for Gelatin-Free Gummy Production

Producing high-quality non-gelatin gummies requires specialized equipment. Here are the key machines you'll need:

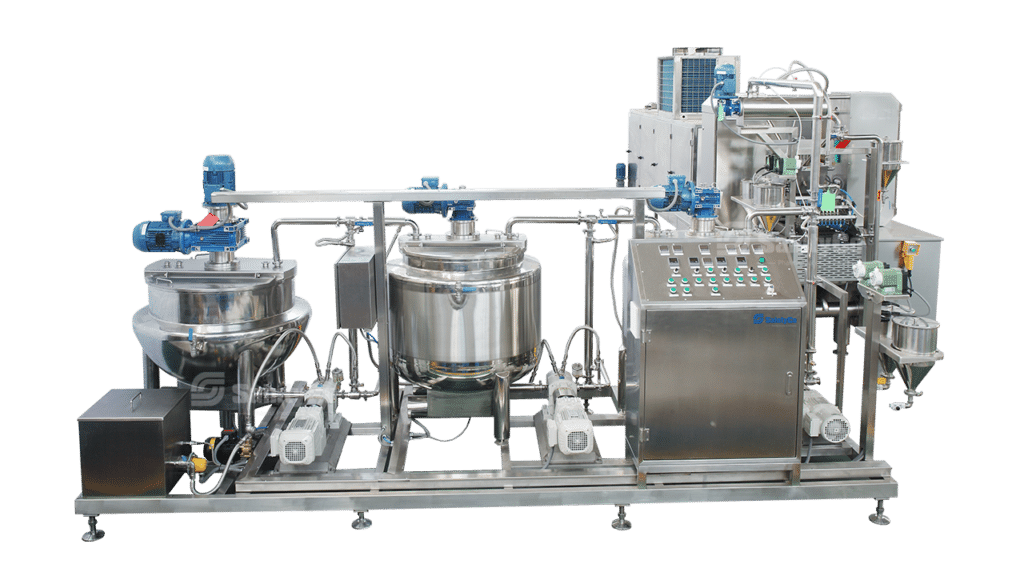

Cooking Systems

The Continuous Cooking System is adept for crafting both gelatin and pectin-based gummies. This setup boasts tanks that dissolve and heat the mix, a transfer pump to keep things flowing smoothly, and a hot water recirculation system that keeps the temperature just right.

- Temperature Mastery: Getting the temperature spot-on is key for melting gelling agents like pectin or agar, ensuring your gummy mix is always silky smooth.

- Mixers: These guys make sure every ingredient gets to know each other really well.

- Heat Exchangers: They're like the thermostat of your system, keeping the heat exactly where it needs to be.

.

Depositing Machines

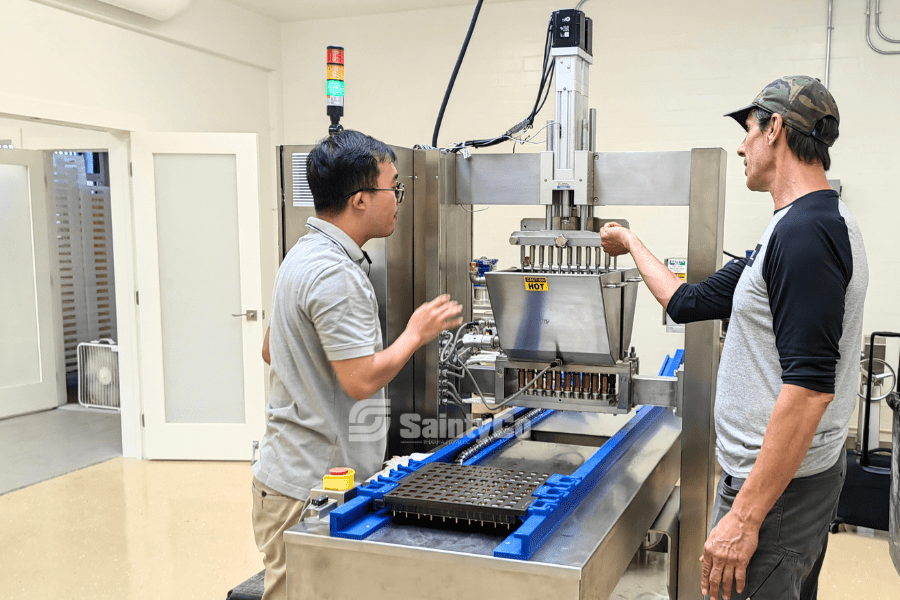

Accurate dosing is crucial for consistent gummy shapes and sizes. Depositing machines use several depositing nozzles and heated hoppers to maintain the proper slurry temperature, ensuring precise and consistent results. Consistent depositing pressure and temperature control are critical to ensuring quality and uniformity.

.

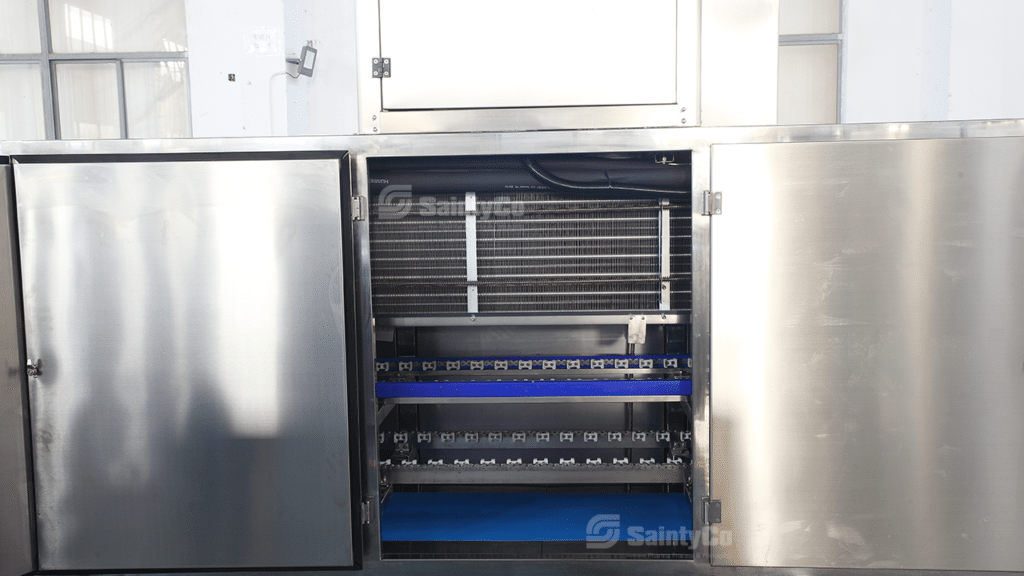

Cooling Tunnels

Controlled cooling is necessary for properly setting gelatin-free gummies. Cooling tunnels guarantee that gummies set correctly and retain their shape, and they frequently include numerous cooling steps for complete setting. Optimizing airflow and temperature gradients can improve gelling efficiency while avoiding flaws such as stickiness or distortion.

.

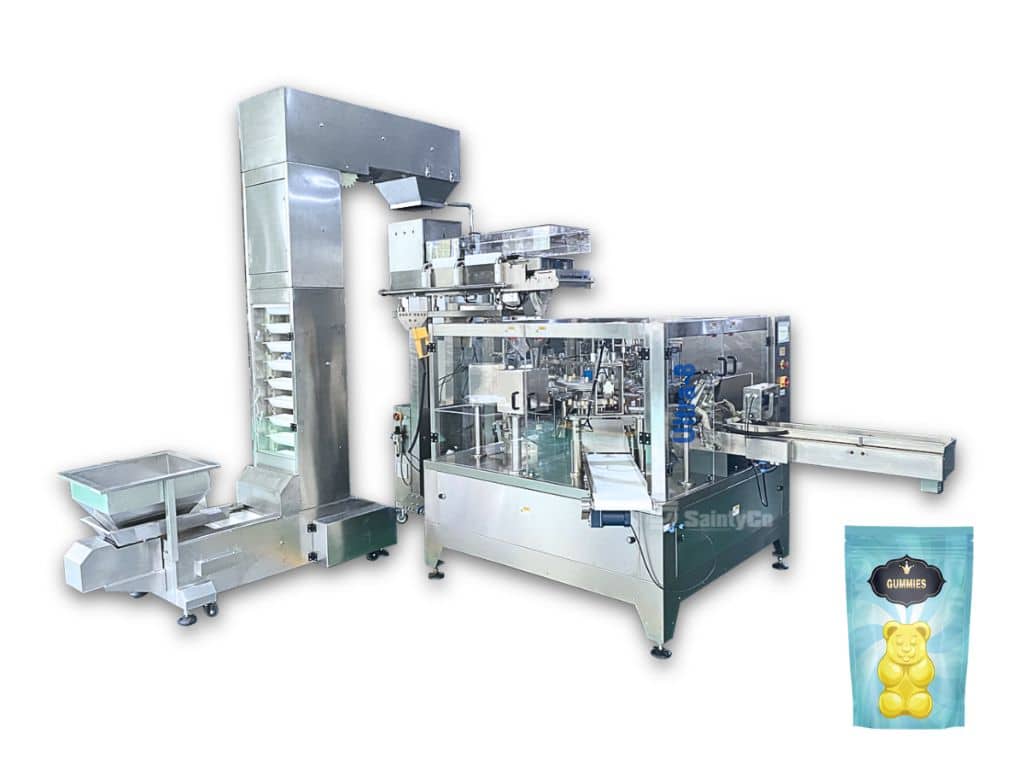

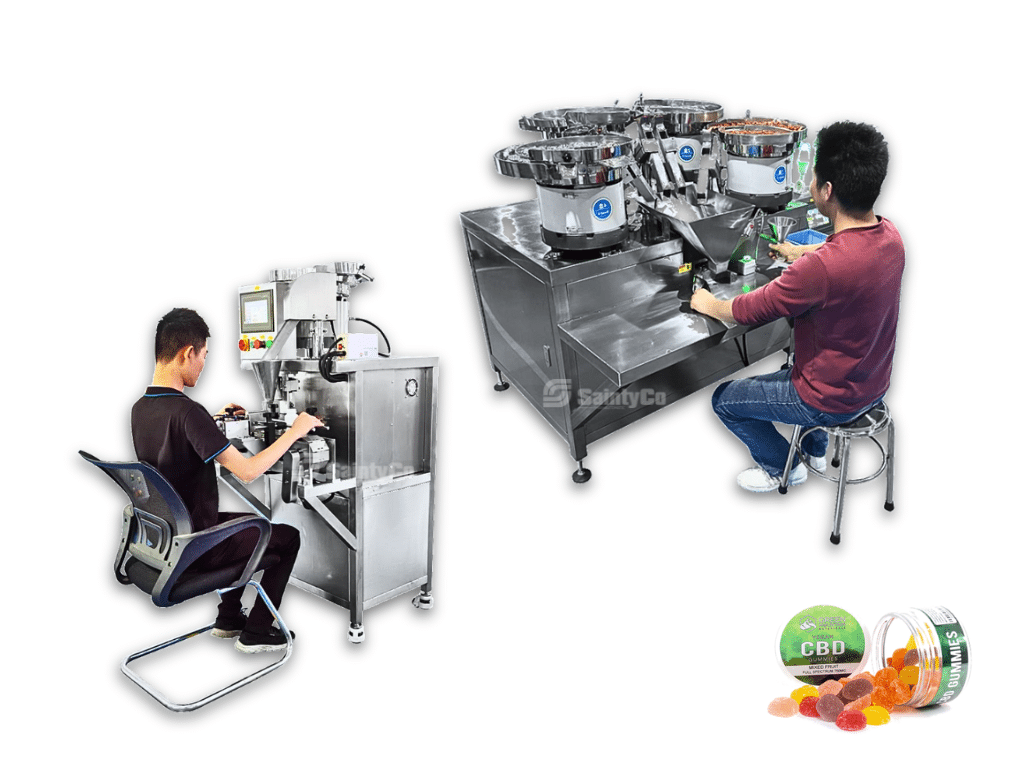

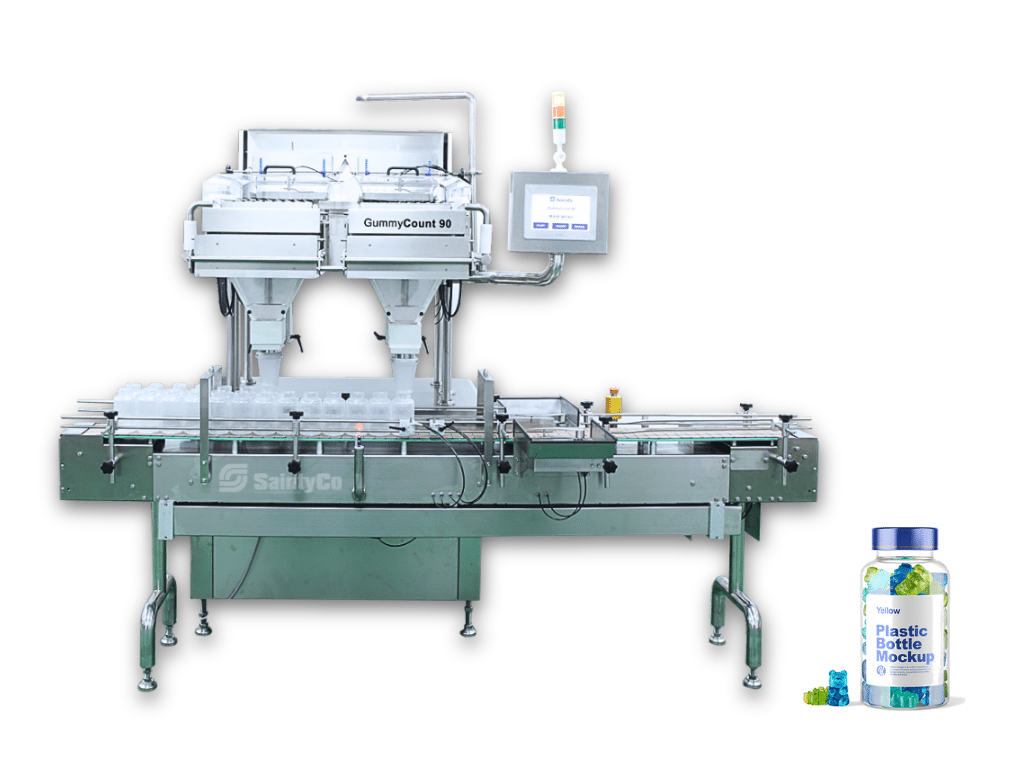

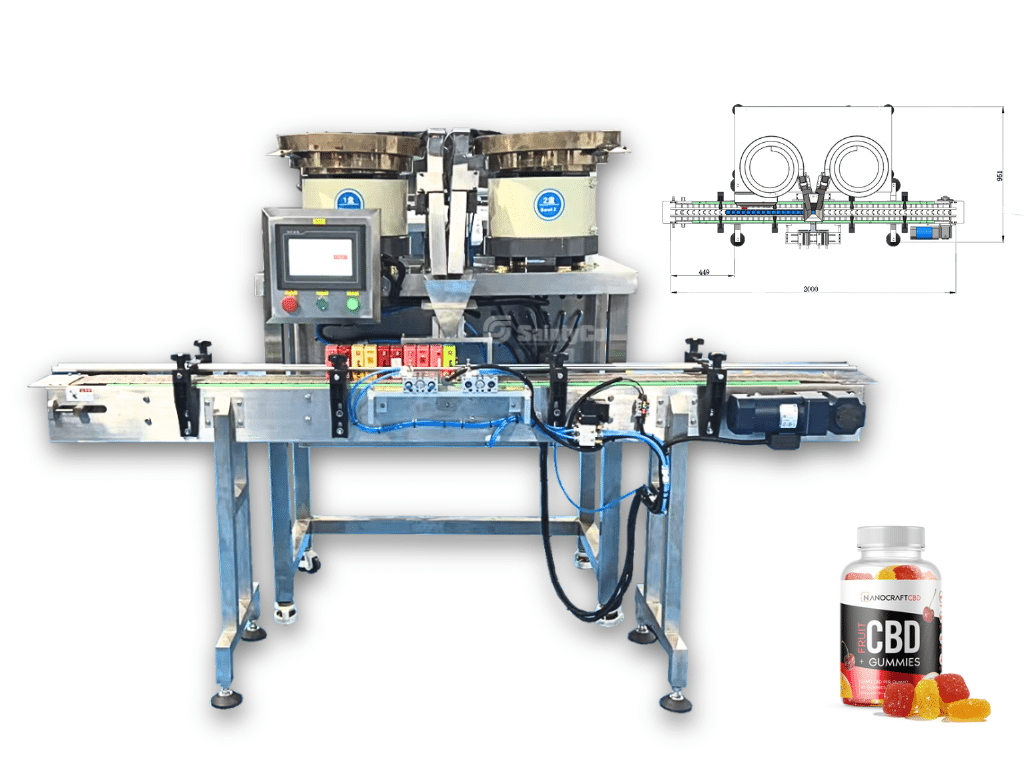

Packaging Lines

Product Quality and Shelf Life: Efficient packaging lines are necessary for maintaining product quality and extending shelf life. They ensure compliance with hygiene standards and include weighers, baggers, and wrappers. Automated packaging solutions improve productivity and reduce contamination risks, ensuring gummies remain fresh and safe for consumption.

Ultra-8 Rotary Pouch Fill and Seal Packaging Machine

with a Multi-Head Weigher

Rapid Channel Gummy Counter

Fully Automatic

Vibration Bowl Counter

.

Advanced Features in Automated Gummy Making Machines for Gelatin-Free Gummies

Modern automated gummy making machines come with advanced features ideal for making high-quality gelatin-free gummies:

- PLC Control Systems: These systems give the manufacturing process exact control and enable real-time adjustments to preserve uniformity and quality.

- Touch Screen Interfaces: Production parameters are shown on touch displays that are easy to use, which helps prevent errors.

- Servo-Driven Depositors: These ensure the right amount of gummies in each mold and help shape and size the gummies. This is important when working with gelatin alternatives like pectin or agar.

- Multi-Color and Central Filling Capabilities: Create gummies with multiple colors and a central filling to increase product diversity.

- Automated Cleaning Systems: Preserve hygienic standards while cutting down on downtime from human cleaning.

- Energy Efficiency: Modern equipment uses less energy, which lowers environmental impact and electric bill costs.

- Integrated Cooling Systems: Ensure the gummies retain their texture and shape after setting correctly.

- Flexibility in Mold Designs: Quickly change molds to produce various shapes and sizes, catering to different market demands.

.

.

Key Features of a Reliable Gummy Production Equipment Supplier

Selecting the right supplier for your gummy production line is like choosing a partner in a dance—coordination is key. Here are a few moves to keep in mind:

- Quality and Certification: Ensure your equipment checks off important boxes like ISO 9001:2015, cGMP/GMP, CE Electrical Certification, and FDA Quality Standards. Top-notch equipment doesn't just perform consistently; it also cuts down on the headaches of frequent repairs and maintenance.

- Local Support and Logistics: Think of local support as your backstage crew. They ensure the show goes on by reducing downtime and smoothing out logistics issues. With a local vendor, you're looking at quicker part replacements and on-the-ground technical support.

- Responsive Feedback and Communication: Clear lines of communication with your equipment supplier can turn a mountain back into a molehill, fast. Regular updates and quick feedback keep your production humming along with fewer interruptions.

.

.

Why GummyGenix by SaintyCo is Your Best Choice for Gummy Production Equipment

SaintyCo provides innovative, accredited, and worldwide-supported equipment for your gummy manufacturing needs. We prioritize quality, sanitation, and speed in order to provide comprehensive solutions for creating gelatin-free gummies.

Our affordable pricing, extensive support, and dependable logistics make us the ideal partner for your organization. Our equipment fulfills the highest food safety and efficiency standards, guaranteeing that your production line operates smoothly and produces consistently high-quality gummies.

.

.

Summary

Having the proper machinery for gelatin-free gummies is critical for your manufacturing process. SaintyCo provides innovative, certified, and globally backed equipment, making us a dependable partner for your gummy manufacturing needs. By investing in the correct equipment and adhering to best practices, you can make high-quality gelatin-free gummies that match market demand while also improving your brand reputation.

.

Let's chat about how GummyGenix by SaintyCo can help you meet your gummy production needs. Please leave an inquiry or schedule a call to get started!