Are you looking to begin your gummy production journey? Semi-automatic gummy machines offer cost-effective and flexible solutions for small to medium-scale production. They provide high precision and quality while being easier to operate and maintain, giving you greater control and reducing waste. This guide will walk you through each step, from mixing raw materials to achieving the final product, ensuring efficiency and quality to save you time and labor.

Step 1: Raw Material Mixing and Cooking

Accurate weighing of ingredients is crucial for perfect gel consistency. Start by measuring the primary ingredients: gelatin or pectin, water, and glucose syrup. Dry blend the pectin or gelatin with sugar, disperse this mixture in water using high agitation in a jacketed kettle with a surface scraper mixer and preheat it to boiling for complete dissolution.

- Heat and Stir: Slowly heat the mixture with thorough stirring until it reaches a syrupy consistency, maintaining a temperature of 140-160°F (60-70°C).

- Add Ingredients: Once the base mixture reaches 75°Bx, add flavor, color, and any other additives. Stir well for a few minutes.

- Adjust Consistency: If the Brix reading is below 78°Bx, continue cooking. If it exceeds 79°Bx, add 1% water. When the Brix level is between 78°Bx and 79°Bx, add the acid solution slowly while stirring vigorously.

.

100L tilt to pour kettle

.

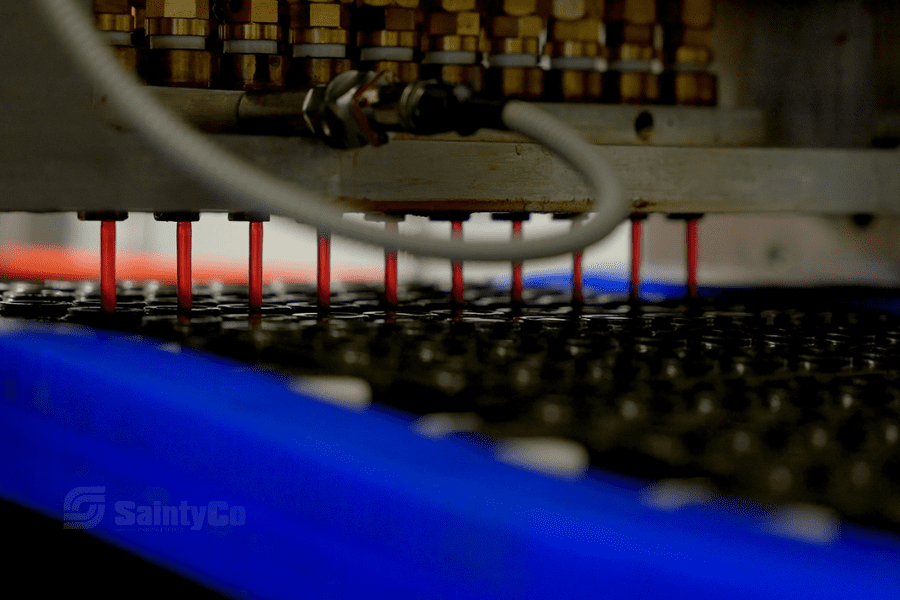

Step 2: Depositing

Preheat the depositor by setting the hopper and depositor to 200°F to maintain the optimal temperature for depositing.

- Pour Syrup: Carefully pour the prepared syrup into the gummy depositor machine's hopper or introduce it through a connecting pipe.

- Position Molds: Place the gummy molds on the depositor's indexing conveyor under the discharge port. Activate the switch to start the depositor. The nozzles will drip the syrup into each mold cavity. The conveyor will then move a new mold into place, continuing the process.

.

On-site photo from our client in Houston, TX, showcasing the efficient SaintyCo DM-50X Gummy Depositor in action.

.

Step 3: Curing and Demolding

Allow the filled molds to cool for 10 to 20 minutes at temperatures between 32 and 50°F (0 to 10°C). Once set, use a pneumatic gummy demolder to efficiently remove the gummies from the molds. Ensure you have a reliable humidity control system to maintain the specified conditions.

.

Gummy Demolder, Pneumatic, no electrical requirements

.

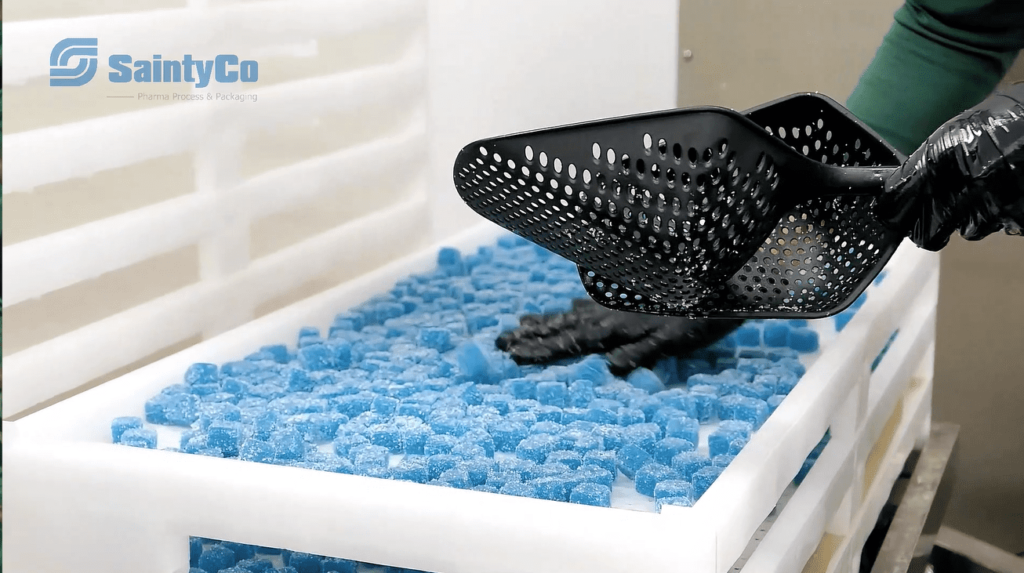

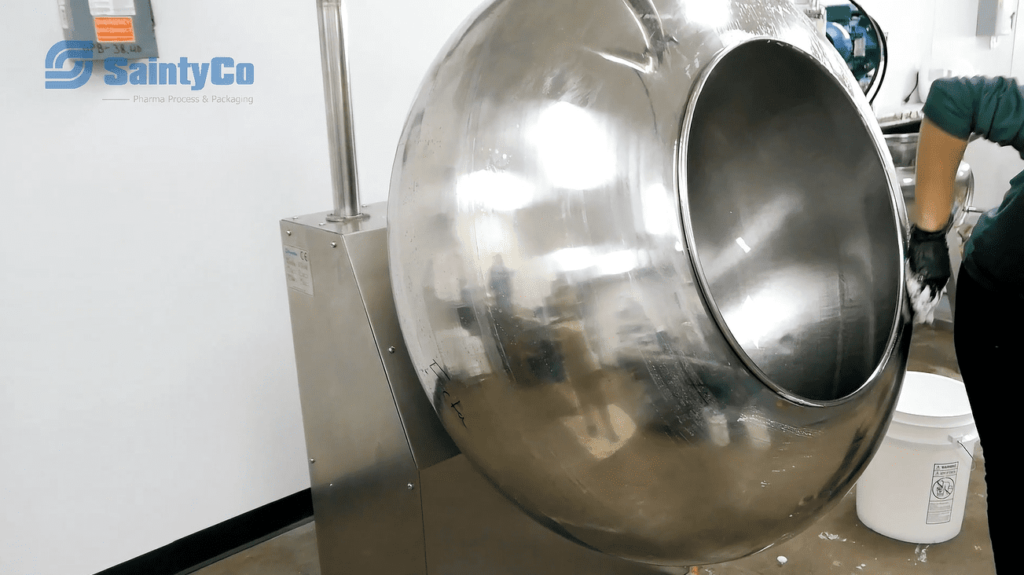

Step 4: Coating

For a finishing touch, coat the gummies with sanding sugar or wax.

- Sanding Sugar Coating: Roll the gummies in sanding sugar immediately after demolding, or use a sugar polishing pan for quicker, more uniform coating.

- Wax Coating: Melt food-grade wax and maintain it at the required temperature. Dip the gummies into the wax solution and let any excess drip off, or use a wax coating pan for more efficient coating.

.

Sugar Polishing Pan

.

Step 5: Drying

Spread the coated gummies on a tray in a single layer. Allow them to dry in a controlled environment with humidity below 40%:

- Pectin Gummies: 25-30°C for 24-48 hours

- Gelatin Gummies: 20-25°C for 48-72 hours

Ensure a dehumidifier maintains appropriate humidity levels in the drying room.

.

.

Step 6: Cleaning and Equipment Maintenance

Maintaining cleanliness and proper equipment maintenance is essential for consistent production quality and hygiene.

- Clean the Depositor: After daily production, pour a neutral detergent solution into the hopper and heat it. Activate the depositor to allow the detergent to clean the nozzles and internal components. Dispose of waste and clean water appropriately.

.

.

- Clean Other Machines: Wipe surfaces with a neutral detergent and run the machine with the detergent solution to clean internal parts.

.

.

- General Maintenance: Regularly check and maintain all moving parts, lubricate as necessary, and schedule monthly maintenance checks.

.

Conclusion

This comprehensive guide ensures a smooth and efficient gummy production process using semi-automatic machines, producing high-quality gummies with consistent texture and taste.

.

This information is provided as guidance only; users must conduct their application tests. GummyGenix by SaintyCo does not assume any responsibility for using this information. Our seasoned team can assist you with any questions concerning machine use. For more detailed information on our gummy production solutions and equipment, visit GummyGenix or SaintyCo's website or contact me at [email protected].

.

Why Choose SaintyCo?

SaintyCo specializes in providing expert automated systems for gummy production tailored to startups, retailers, and large manufacturers globally.

.

Our Gummy Machines' Advantages:

- High Efficiency: Production lines with capacities from 6,000 to 240,000 gummies per hour.

- Advanced Technology: Our machines, featuring servo-driven systems, accurate temperature control, and hygienic designs, ensure reliable and consistent production.

- Versatile Equipment: Our equipment is suitable for producing CBD, THC, vitamin gummies, and more, meeting diverse manufacturing needs.

.

Customer-Centric Approach

We focus on understanding and addressing our clients' pain points, such as reducing production costs, improving production speed and accuracy, and ensuring high-quality output with minimal waste.

.

Compliance

Our gummy machinery complies with international standards, including cGMP, ISO 9001:2015, CE Electrical Certification, and FDA Quality Standards. It is perfect for pharmaceutical-grade, high-precision production. These features enable you to streamline your production process, save labor, and maintain high hygiene standards.

.

Global Support

SaintyCo provides global sales support and after-sales service to ensure smooth operation and maintenance of your equipment.

.

Let's bring your dream gummy to life with our state-of-the-art production lines and expert support! Contact us today to get started.