What Are the Most Important Gummy Manufacturing Equipment for Scaling Production?

Gummy candies have taken the confectionery world by storm, and scaling production to meet demand requires the right equipment. From depositors to packaging machines, each piece plays a vital role. In this article, we’ll dive into the key equipment necessary for a successful gummy manufacturing process.

How Can I Stop My Gummies from Curing Too Quickly in a Gummy Depositor?

Are you tired of your gummies setting too fast, leaving them with an undesirable texture? You’re not alone! This guide dives into the intricacies of gummy production, offering you expert tips to control temperature, Brix levels, acid timing, and humidity, ensuring your gummies achieve that perfect chewiness every time.

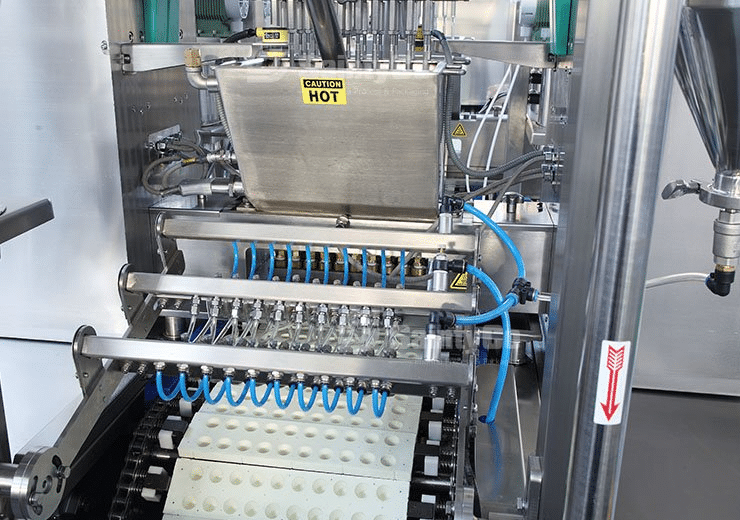

Gummy Depositors: What Are the Most Common Issues When Using Them?

Gummy depositors are vital in the confectionery industry, but they can encounter several issues. This article explores the most common problems such as inconsistent filling, clogging, and temperature sensitivity, while providing actionable insights to overcome these challenges. By understanding and addressing these issues, manufacturers can optimize their production processes and ensure high-quality gummy products.

Gummy Production Tips: How to Maintain Your Gummy Depositor Effectively?

Maintaining a gummy depositor is essential for efficient production and high-quality output. By focusing on regular cleaning, inspections, and operator training, I can ensure smooth operations and minimize downtime. Let’s dive into the key components and innovative technologies that can help enhance maintenance practices.