About GummyGenix

Designing, Manufacturing, Integrating and Servicing Gummy Processing & Packaging Automated Solutions

Rooted in Innovation, Complete solutions & Customer Support

GummyGenix, a sub-brand of SaintyCo (Sainty International Group), leverages its parent company’s pharmaceutical machinery expertise to provide cutting-edge automated gummy production and packaging solutions worldwide, tailored for the confectionery, cannabis, and nutraceutical industries. Our genuine commitment lies in helping you to be more successful.

From compact R&D gummy depositor units to versatile gummy production lines covering kitchen setups and packaging machinery for finished gummies, our solutions are designed to save time and resources, boosting your profitability.

Our value goes beyond machinery. We offer comprehensive support, including customized gummy formulations, facility layout design, manufacturing operations, and training. With two decades of partnership-building, we are dedicated to bringing innovation, one-stop solutions, and proactive customer service to you.

Certified Excellence: Efficiency, Safety, Compliance

International Standards Organization (ISO) 9001:2015

CE Electrical Certification

Food and Drug Administration (FDA) Quality Standard & Certification

UL Certification (US)

SGS-CSTC Testing Inspection Certification

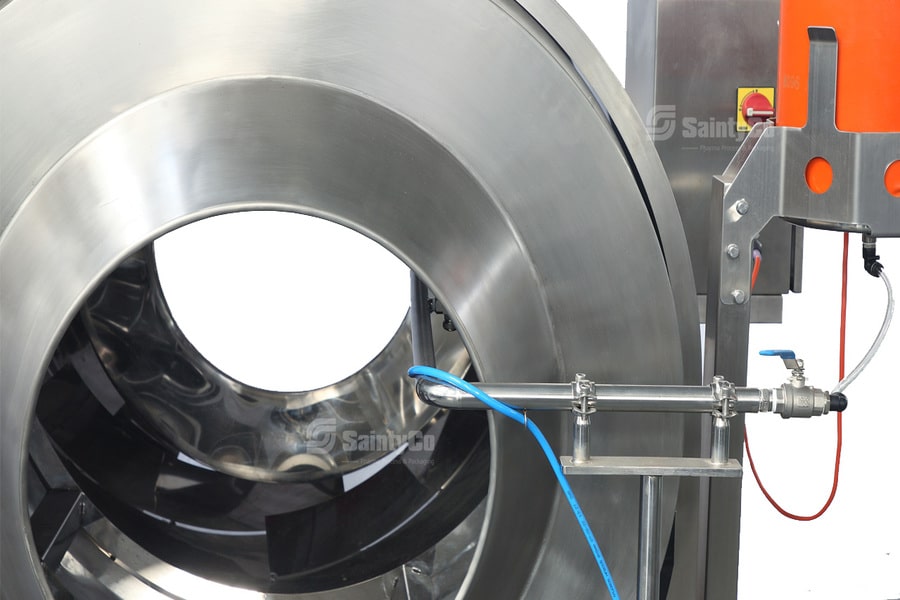

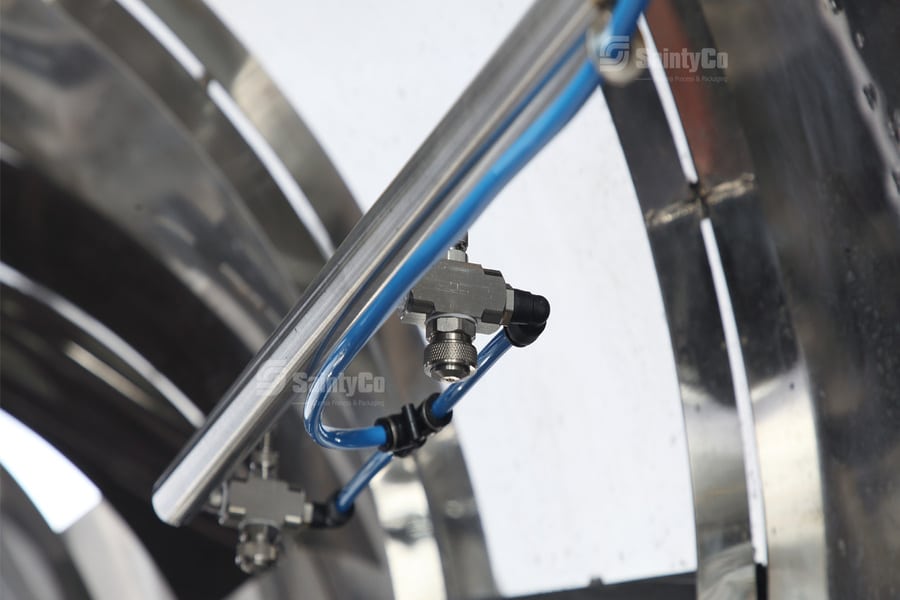

We specialize in advanced gummy production machinery, prioritizing safety, reliability, and cutting-edge technology. We focus on premium-grade materials and high-quality manufacturing processes conforming to compliance with WHO, cGMP, GMP, 21CFR part II, and CE standards for food and pharmaceuticals. The company’s Lean manufacturing system enhances equipment reliability by standardizing processes, using modular design, reducing delivery times, and optimizing costs.

Our machine meets global regulatory standards, enabling confident operation in international markets.

Join us for an in-person demonstration. Experience our commitment firsthand.

National Patent Certificate for 2-in-1 Gummy Depositor

National Patent Certificate for Servo-Controlled Gummy Depositing Machine

Dedicated to product Innovation

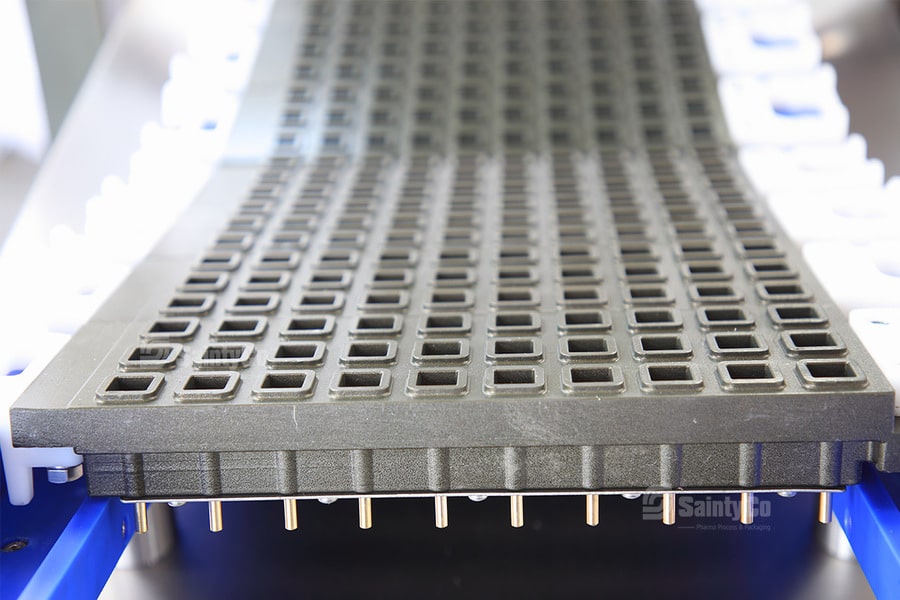

The latest engineering advances allow us to develop features such as double dosing, gummy counting, quick changeover, or micro-dosing.

We obtain maximum efficiency from each user-friendly machine. Fast and highly resistant equipment offers an OEE of over 95%, giving you more rapid production and profitability.

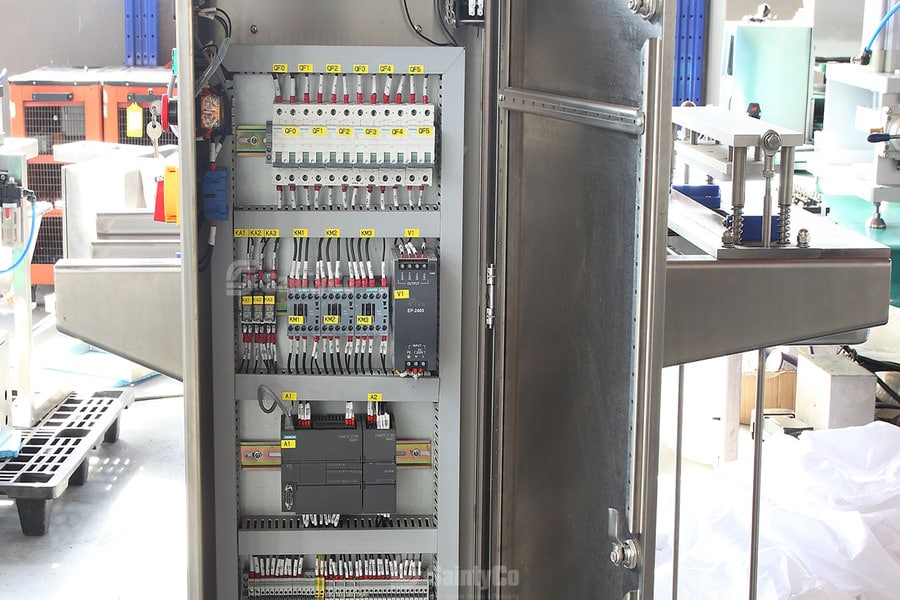

Our trustworthy suppliers

It also relies on first-level technological partners such as: Schneider, Siemens, Omron, Emerson, SpiraxSarco, Panasonic, Festo and Endress & Hauser that provide reliable, durable and universal components.

You can be sure of the quality you receive

All GummyGenix equipment goes through a complete Factory Acceptance Test (FAT) covering visual inspection, functions, controls, and safety.

Next, all components are tested to guarantee accuracy and calibration. It covers all aspects of the machine, such as temperatures, pressure, speed, rotations, dosage, safety etc. We document all tests and know the complete story of the machine.

Multinational Support

Bradenton, Florida

Toronto, Canada

Shanghai, China

With our sales and technical teams travelling across regions including the U.S., Canada, the EU, and international markets, accessing our technical support and replacement services is convenient for you.

Visit our innovation Center in Florida

Seeing is Believing

Let us show you the ins and outs of our solutions for you to make well-informed purchase decisions

Test Innovations

Test your product potential with experts in small batch trials, including recipes, products, processes

Equipment Workshops

Develop skills and knowledge of GummyGenix equipment operation and maintenance

Latest Insights

Explore industry trends, gummy products, and tech innovations to address your challenges

Bridging Program

Boost uptime using our replacement machines and resources to bridge production gaps

Easy to Travel

10 Minute drive from Sarasota Airport

Our clients share their recommendations

Let's talk about your project

Discover Our Automated Solutions Now!

- Awareness of your needs

- Recommend solutions for your reference and comparison

- Offer reasonable quotation

- 360° After-Sales Support